Energy & Power

Velo3D System Chosen for Aftermarket Gas Turbine Parts Production

Additive manufacturing will help keep aging engines operational with greater flexibility and shorter delivery times than traditional MRO supply chains.

Read MoreDirected Energy Deposition (DED) Error Turns Nozzle Into Chess Piece — AM: Why the Failure? #3

Chess pieces are often 3D printed as demo parts, but this one was an accident! What happened? The answer involves heat transfer.

WatchEssentium Printer Features Independent Dual Extrusion System

The company is also introducing Essentium PP-CF, a new high-performance material for chemically resistant and low surface energy AM parts.

Read MoreMetal 3D Printed Part Has Unplanned Feature, Not Part of the Design — AM: Why the Failure? #2

This component for the oil and gas industry features a shelf through the lattice structure that does not appear in the CAD model. How did it get there? The answer does not involve STL, but we talk about that anyway.

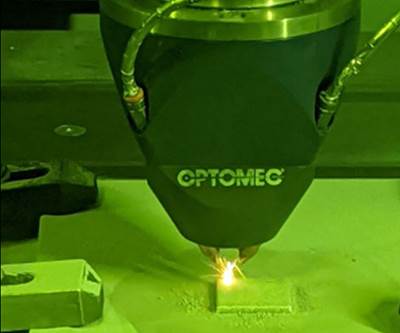

WatchOptomec Metal 3D Printers Designed for Research, Production

Compact Directed Energy Deposition (DED) machines include automation for batch processing.

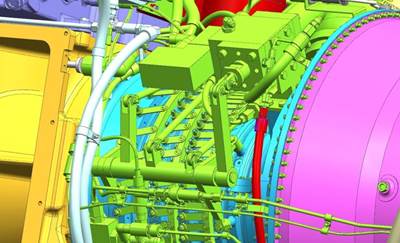

Read MoreTopology Optimization Delivers Nonintuitive Design Features for Legacy Part (Includes Video)

Refurbishing a legacy turbine engine for energy efficiency provided the opportunity to demonstrate topology optimization in concert with metal 3D printing. The design for this torque arm comes from computer simulation insight refined with a human touch.

WatchOptomec's Aluminum 3D Printing Capability Uses Directed Energy Deposition

Aluminum DED processing is said to open the transportation and aerospace industries to AM and repair of complex aluminum alloy parts.

Read MoreOptomec Releases Pure Copper DED Process

Optomec has developed a pure copper Additive Manufacturing process using Optomec’s LENS directed energy deposition (DED) systems.

Read MoreSLM Solution’s Powder-Bed Fusion Machine Emphasizes Efficiency

Formnext 2019: SLM Solution’s SLM 500 powder bed fusion machine features improved gas flow along and quad-700W laser technology, enabling increased productivity.

Read MoreExtrude Hone Thermal Energy Method Removes Metal AM Supports

Rapid 2019: Extrude Hone showcases a proprietary approach that uses thermal energy method (TEM) to address metal support structure removal.

Read More