Brackets

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreCan Additive Manufacturing Compete With Conventional Manufacturing on Cost?

When it can, says Evolve, the design advantages of AM find their way in. The company is beginning to ship its high-speed AM system for polymer part production.

Read More3D Printed Brackets Secure Fuel for Nuclear Power: The Cool Parts Show #45

Can additive manufacturing improve the design of nuclear power plants? These steel brackets are the first step.

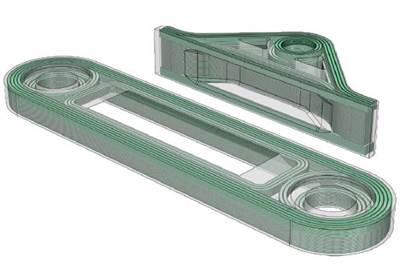

Watch3D Printed Composite Bracket Versus Machined Steel: The Cool Parts Show #41

Can a 3D printed composite bracket work as well as one machined from steel? Can it also be faster to make and cheaper to produce? In this episode of The Cool Parts Show we explore a new way of manufacturing a bracket for a helicopter door hinge, and similar small parts today made from metal.

WatchAMGTA Commissions Its First Life Cycle Assessment Research Project

The study will be ISO 14040 compliant and compare the cradle-to-grave environmental impacts of a jet engine low pressure turbine bracket produced through traditional manufacturing methods with one that is produced via additive manufacturing.

Read MoreHow Tilt Hydrometer Fights Supply Chain Disruption with 3D Printing

The maker of a digital hydrometer for beer brewing keeps its supply chain and product flexible through selective laser sintering of a critical component.

Read MoreCadillac Blackwing Models Are First GM Cars Using Additive Manufacturing for Full-Scale Production

Three functional components are 3D printed thanks to cost savings and design freedom. Layers lines on the shift knob signify this advance.

Read MoreFiber-Reinforced 3D Printing Expands Control, Applications for Composites

9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste, and more precisely control the structure of preform composites.

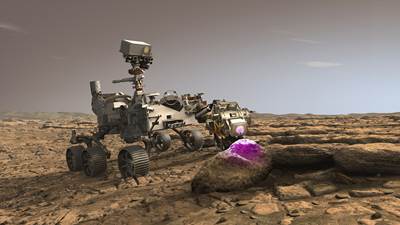

Watch3D Printed Parts on the Mars Perseverance Rover: The Cool Parts Show #23

The Perseverance parts made through additive manufacturing are extreme examples of lightweighting. We have replicas of the 3D printed parts that were sent to Mars.

ListenMars Rover Instrument Is Manufacturing Challenge, 3D Printing Victory

A critical instrument on the Perseverance rover requires five components that could only be made via additive manufacturing. Carpenter Additive overcame obstacles to produce them.

Read More