For home brewers, a hydrometer is an eye on the inside of the beer tank. The device measures the specific gravity of a batch of beer, offering clues as to how fermentation is progressing. When a beer reaches its expected final gravity, brewers can feel confident about its flavor, body and alcohol content—all factors that contribute to consistency across batches. While a hydrometer isn’t a required piece of equipment for home brewing, it can be an invaluable tool for ensuring recipe success.

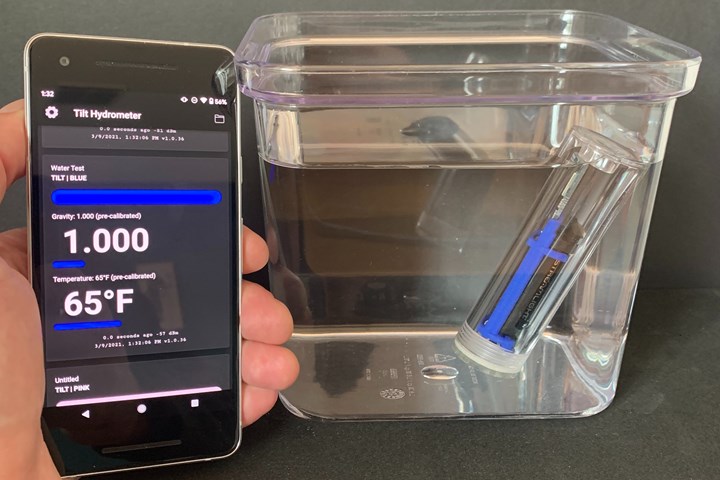

"It brings all this information to home brewers they wouldn’t have access to otherwise,” says Noah Neibaron, cofounder of Tilt Hydrometer and an avid home brewer himself. While it’s possible to take samples from a batch of beer and derive this information manually, the testing process is lengthy and opening the fermenter risks contamination. Tilt offers an alternative with its product, an affordable wireless digital hydrometer that floats in the beer itself and delivers this data automatically, with no need to open the tank until fermentation is complete.

The Tilt Hydrometer allows brewers to measure the temperature and specific gravity of a batch in progress without opening the tank. The watertight device floats directly in the beer and relays information back to the user’s smartphone through a Bluetooth connection. Photo Credit: Tilt Hydrometer

In essence, Tilt Hydrometer is offering users a new, simple and affordable way to improve the product they are making — not unlike the way that accessible, affordable 3D printing has enabled the making of this instrument. Through 3D printing provided by a manufacturing partner, Tilt has been able to develop and produce a key component of its hydrometer. But the development isn't done; although this part is in continuous production now, Tilt accepts and expects that it will change — and for this reason, 3D printing will continue to be the right manufacturing method.

The Bracket That Holds It All Together

Tilt Hydrometer offers two main products today, its original hydrometer aimed at home brewers and the Tilt Pro for small- to medium-sized craft breweries. In both cases, the device is cylindrical, only a few inches tall, and “deceptively simple,” Neibaron says. The company’s hydrometers consist of an accelerometer and temperature sensor to capture information; a Bluetooth antenna to relay the data to a user’s smartphone; weights to serve as ballast; a battery; a bracket that holds these internal components in place; and a watertight, cylindrical capped case to keep everything enclosed. The hydrometer must seal, but must also allow the user to open it in order to change batteries as needed.

The part in question is the 3D printed bracket—dyed red here. Photo Credit: Tilt Hydrometer

Neibaron formed the company circa 2011 with two friends who brought electrical engineering and marketing expertise, but it took several years to develop the original Tilt Hydrometer product. As the team progressed from home-grown prototypes (an early device utilized the accelerometer from a Wii controller for instance) to finer design iteration, it worked with a number of manufacturing processes and service providers, including 3D printing specialist Shapeways.

While most of the components used in the hydrometer are off-the-shelf parts, the one that proved critical is custom: the plastic bracket that holds the other pieces in place. If the instruments move, or the weights shift and affect the way the device floats, its accuracy will be thrown off. The bracket is removable, but must be precise enough to sit inside the tube with almost a "spring fit," Neibaron says.

In the product development stage, Tilt had these brackets milled from plastic at a cost of about $30 per unit. The cofounders always saw this cost as a difficulty that would need to be overcome in order to offer their final product at a price point attractive to home brewers. Injection molding was considered as an option, but would have meant molding the part in two pieces, introducing an assembly step to glue the parts together and potential weakness at the joint.

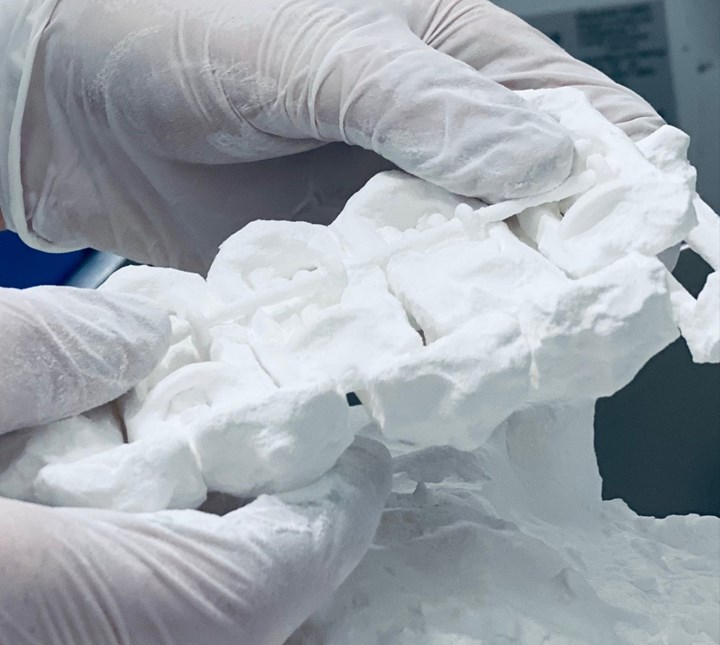

Tilt Hydrometer decided instead to go into production with a different technology that had served it well in prototyping: selective laser sintering (SLS). Rather than investing in injection mold tooling or continuing to pay the high cost of milling, Tilt is now able to source this bracket directly from Shapeways through the company's on-demand manufacturing services. (Automated workflows and digitized processes make this model possible; Shapeways recently celebrated the printing of 20 million parts for more than 1 million customers ranging from small businesses to large enterprises.)

The part is 3D printed as a single piece from durable nylon and dyed a range of colors. (Brewers using multiple Tilt hydrometers select different colors to distinguish between batches.) Shapeways can provide the printed parts within just a few days, allowing Tilt to order them as needed rather than keeping large amounts of brackets in inventory.

The brackets are 3D printed in nylon using selective laser sintering (SLS), then depowdered as shown here before being dyed. Shapeways can produce small batches of the part as needed, reducing the need for Tilt to stockpile inventory. Photo Credit: Shapeways

Although the SLS 3D printing process results in a slightly higher price per part than injection molding, it comes without an expensive investment in mold tooling, the need for glue, and the cost of labor to assemble the bracket. While Tilt Hydrometer outsources the component manufacturing, all the final assembly for its products happens at its Santa Rosa, California, facility so the company has a vested interest in keeping this process fast and simple.

“We don’t want to be spending time assembling things,” Neibaron says. “It’s worthwhile to pay a dollar or two more for a 3D print that can be just one piece.”

The 3D printed brackets cost slightly more per part than injection molding, but selective laser sintering allows the component to be made in just one piece, which saves time in assembly. A “cage” fixture printed with the parts organizes the brackets into groups of 10, making it easier to count the pieces needed. The cage is later cut off with scissors. Photo Credit: Shapeways

Product Design, Supply Chain Flexibility Through 3D Printing

Since its first sale in 2015, Tilt Hydrometer has sold tens of thousands of its product for home brewers. It recently launched the Tilt Pro, which offers similar data and insight to commercial breweries without the time or cost associated with manually collecting samples.

“It’s like having a technician come in and manually take a reading every 15 minutes,” Neibaron says. “it would be an incredible amount of data to capture, and to do it manually would be astronomically expensive.” For a small craft brewer, the automated data capture possible with a digital hydrometer could enable levels of consistency and quality on par with a larger company, without major added investment in workforce or equipment.

“It’s like software — you can make a little change, and it’s fixed.”

Not long after the introduction of the Pro line, however, Tilt Hydrometer found that the battery holder was failing to keep the battery in position. The company sourced a new holder but its design made it possible to put the batteries in backwards, which would fry the device. Working with Shapeways, Tilt developed a 3D printable polarity protector to prevent mis-insertion of the battery.

“Without that protector, we would have had tons of returns from fried boards,” Neibaron says. “But with 3D printing we can anticipate these kinds of issues and 3D print a solution. It’s like software — you can make a little change, and it’s fixed.”

The colored 3D printed bracket inside each hydrometer is the key to holding all the instruments in place and ensuring accurate readings. Tilt has been able to adapt its supply chain to utilize the electronics that are available by altering the geometry of this 3D printed piece. Photo Credit: Tilt Hydrometer

This small alteration to the Tilt Hydrometer Pro speaks to the company’s larger philosophy around production. Where other manufacturers have worked toward developing the final, “best” version of a product, Tilt sees greater opportunity in staying flexible. Supply chain disruptions such as recent electronics shortages caused by the COVID-19 pandemic are less disruptive to Tilt because of this software-like, continuous development mindset. Working with Shapeways’ user application team makes it simple for a small business like Tilt to make modifications, optimize new designs for 3D printing and scale production as needed. The use of 3D printing for brackets and other custom parts means that Tilt is never locked into a particular supply of sensors, weights or enclosures. On-demand manufacturing of the printed parts makes it possible to adapt the product on the fly, utilizing whatever other components are at hand.

“We don’t have to stock out or pay huge prices because there’s not much available. We can source an alternate part and 3D print something to make it all work,” he says. “Having flexibility with 3D printing can save you.”

Related Content

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

The Future of Jewelry Manufacturing Is Custom, On Demand and Perfectly Sized

The Melvin sisters launched their startup, The Future of Jewelry, when they couldn’t find matching signet rings. Now, customers can design exactly the ring they want, to be produced affordably through 3D printing and/or lost wax casting.

Read MoreAngled Makes It Possible for Anyone to Launch a 3D Printed Product

The online store utilizes open capacity at its sister 3D printer farms for on-demand production with no startup costs, allowing designers to sell physical products as easily as digital ones.

Read MoreVideo: Periscope Case Shows 3D Printing for Niche Manufacturing

Manufacturing without mold tooling allows the production quantity to be tailored to the market size.

Read More

.jpg;width=70;height=70;mode=crop)