Aerospace

Drones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

WatchCollins Aerospace Chooses PrintSky for Flight Actuation Project

PrintSky will use its expertise to develop flight actuation systems that can resist mechanical loads, dissipate heat emitted by the components, and be tight and insensible to electromagnetic disturbances.

Read MoreEOS, Hyperganic Partnership to Elevate Space Components

Integration of Hyperganic Core, an AI-powered engineering software platform, with EOS’ digital additive manufacturing solutions aims to advance the space propulsion field.

Read MoreGeneral Atomics Aeronautical Systems Establishes Additive Design, Manufacturing Center

The center focuses on additive manufacturing applications, R&D, large-scale tooling and next-generation flight hardware to streamline the manufacturing of unmanned aircraft systems.

Read MoreOptomec, Acme Manufacturing Collaborate on Fully Automated Work Cell

Said to be the industry’s first fully automated work cell for the additive repair of turbine parts, the turnkey solution includes seamless integration of preparation, additive repair and finishing functions.

Read MoreFarsoon Assists in 3D Printing of Large Combustion Chamber

Farsoon’s technology also enables an accelerated design-validation cycle of 80% faster compared to conventional manufacturing processes.

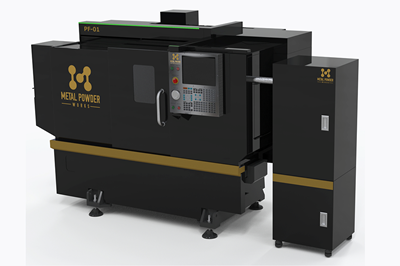

Read MoreMetal Powder Works Joining Additive Manufacturing Production Campus

The 10,000-square-foot space at Neighborhood 91 will function as MPW’s main production facility, enabling it to grow production capacity by a factor of eight times.

Read MoreVelo3D Adds StarHagen to Contract Manufacturer Network

StarHagen is a provider of high-quality production parts for aerospace companies and specializes in manufacturing with extreme precision for prototype and production-volume manufacturing.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreMilitary Aircraft Undergoes Testing With Additively Manufactured Parts

Hardware produced as part of the AMNOW Program undergoes flight testing on operational aircraft.

Read More