Aerospace

Optomec, Acme Manufacturing Collaborate on Fully Automated Work Cell

Said to be the industry’s first fully automated work cell for the additive repair of turbine parts, the turnkey solution includes seamless integration of preparation, additive repair and finishing functions.

Read MoreFarsoon Assists in 3D Printing of Large Combustion Chamber

Farsoon’s technology also enables an accelerated design-validation cycle of 80% faster compared to conventional manufacturing processes.

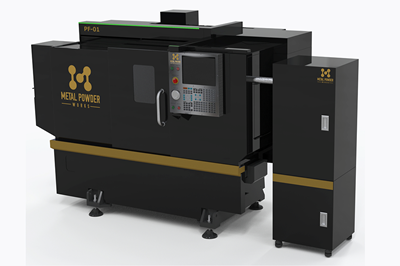

Read MoreMetal Powder Works Joining Additive Manufacturing Production Campus

The 10,000-square-foot space at Neighborhood 91 will function as MPW’s main production facility, enabling it to grow production capacity by a factor of eight times.

Read MoreVelo3D Adds StarHagen to Contract Manufacturer Network

StarHagen is a provider of high-quality production parts for aerospace companies and specializes in manufacturing with extreme precision for prototype and production-volume manufacturing.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreMilitary Aircraft Undergoes Testing With Additively Manufactured Parts

Hardware produced as part of the AMNOW Program undergoes flight testing on operational aircraft.

Read MoreVelo3D Qualifies Copper Alloy for Use With Its Sapphire Printers

Velo3D has qualified the NASA-developed GRCop-42 alloy for use with its Sapphire family of printers to deliver the conductivity of copper with high strength for aerospace applications, such as rocket engine combustion chambers.

Read MoreHow An Airline Addressed Supply Chain Issues with 3D Printing

COVID-19 not only grounded most of Scandinavian Airlines’ (SAS) fleet in 2020, but also limited its access to engine covers critical for safe storage. CNE Engineering used BigRep machines to 3D print molds to produce the covers.

WatchHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreCollins Aerospace Opens North Carolina Additive Manufacturing Center

New facility expands company’s global repair capabilities at Monroe, North Carolina, campus

Read More