Dyndrite Corporation

1201 3rd Ave.

Suite 20-121

Seattle, WA 98101 US

800-995-1038 | 800-995-1038

info@dyndrite.com

dyndrite.com

IS THIS YOUR COMPANY?

As Seen On Additive Manufacturing

Editorial, News, and Products

-

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

-

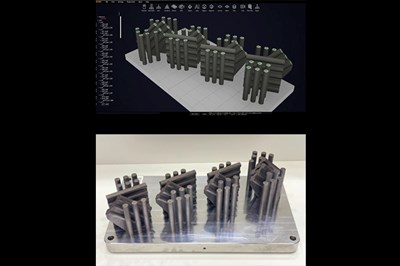

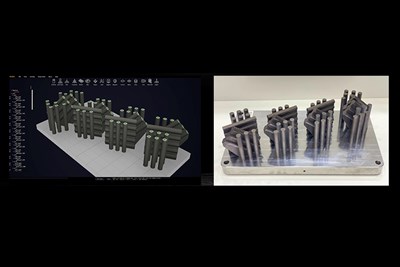

Dyndrite SMART Script Automates Generation of 3D Layouts That Adhere to ASTM/ISO Standards

Developers say that automating this process enables manufacturers to achieve approximately 99% labor savings, eliminating human error and accelerating workflows across multiple machines and materials.

-

Dyndrite Enhances LPBF Pro Software for Expanded Program Control

The updated Dyndrite LPBF Pro offers expanded supports control, integrated learning and expanded Renishaw metal 3D printer compatibility.

-

AM Materials Consortium Selects Partners for LPBF Fabrication and Testing

The consortium is developing open LPBF parameter sets to streamline machine, material and process qualification, with the goal of expediting customers’ process development leading to serial production.

-

Dyndrite’s 3D Print Preparation Software Now Supports HP MJF Printers

New GPU-powered software to bring Dyndrite performance and advanced capabilities to HP MultiJet Fusion polymer and metal Jet 3D printers. Dyndrite is accepting beta users via its Early Adopter Program.

-

AM Workshop at IMTS: Succeeding With Powder Bed Fusion

A half-day event at the International Manufacturing Technology Show focuses on tactics for success for machine shops and other manufacturers preparing to embrace production 3D printing via powder bed fusion.

-

America Makes Announces Recipients of $2.9 Million Defense Project Call

The project award winners are tasked with demonstrating data gathering and analysis methods to drive industrywide metal additive manufacturing operations acceptance.

-

Dyndrite’s LPBF Pro Software Enhances Precision, Traceability, Repeatability for 3D Metal Printing

The software for laser powder bed fusion streamlines processes by enabling the development of innovative parameter strategies and optimization routines, while eliminating manual build preparation hassles.

-

Dyndrite, Constellium, Elementum 3D, Sandvik Establish Materials Consortium for 3D Metal Printing

This joint effort aims to make laser bed power fusion (LPBF) powder parameters and related testing data for common materials freely and publicly available to end users, enabling increased knowledge sharing, better outcomes, and faster adoption of materials and techniques.

-

Dyndrite Powers BCN3D’s High-Viscosity, Production-Oriented VLM System

The collaboration brings users high-performance, end-use resin part printing with GPU-powered automated production software.

-

Dyndrite Joins NMIS to Advance 3D Metal Manufacturing Research

Dyndrite has joined NMIS to help develop build recipes and shareable knowledge in materials process development across all major laser powder bed fusion OEM file formats.

-

Dyndrite, MIMO Technik, Astro Collaborate on Machine, Material Qualification for 3D Metal Printing

The companies chose to collaborate on the development of the Mastro process in order to streamline and automate a closed-loop source for additive production and qualification.

-

Dyndrite Joins ASTM to Provide AM Reference Data

Collaborative effort aims to create shareable reference datasets that drive consistency across the industry, accelerating qualification and adoption of metal additive manufacturing.

-

Dyndrite, UPM Work to Bring Data Intelligence to Metal 3D Printing Build Plates

The collaboration aims to reduce print failures and enable reliable supply chain for additive manufacturing production.

-

Dyndrite Collaborates With AMFG for Cross-Platform 3D Metal Automated Production

AMFG powered by Dyndrite is an integrated solution that is said to unlock the full potential of metal 3D printing by bringing order-to-part automation, eliminating bottlenecks and streamlining the entire production process for increased efficiency and cost savings.

-

Dyndrite, Novanta Collaborate to Enhance Laser-Based AM Metal Printing Machine Capabilities

The companies are working to create proof-of-concept, enabling Dyndrite software to directly generate low-level scanning trajectories for use with Novanta hardware.

-

Dyndrite End-User Software Expands Development for LPBF Machines

System supports multioptic build strategy operations and laser parameter control limited only by vendor openness.

-

Dyndrite, SLM Solutions Cooperate to Maximize Digital Manufacturing Software Tools

The companies are working together to enable users to fully create SLM parameters and tool paths to fit their individual needs, maximizing materials development and application or part-specific build rate strategies.

-

Impressions and Trends from RAPID + TCT 2021: AM Radio Bonus

Peter Zelinski, Stephanie Hendrixson and Julia Hider discuss what they saw, heard and learned at RAPID + TCT 2021 in a special episode of the AM Radio podcast plus slideshow.