AM Materials Consortium Selects Partners for LPBF Fabrication and Testing

The consortium is developing open LPBF parameter sets to streamline machine, material and process qualification, with the goal of expediting customers’ process development leading to serial production.

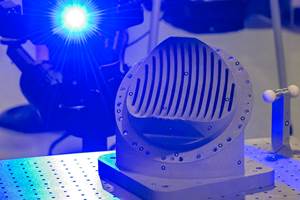

Build plate showcases a qualification build studying material defect formation using parametrically defined and varied parameters. Created by MIMO Technik Inc. with testing by Astro Mechanical Testing Laboratory and printed on SLM Solutions’ 500 3D metal machine. Source: Dyndrite

Dyndrite and the AM Materials Consortium have selected Mimo Technik and Astro Mechanical Testing Laboratory as their lead fabrication and testing partners for developing open laser powder bed fusion (LPBF) parameter sets for consortium members in the U.S. The consortium is utilizing the companies’ Mastro method and Dyndrite software to streamline and accelerate machine, material and process qualification, with the goal of expediting customers’ serial production process development for additive manufacturing (AM).

In late 2023, Dyndrite joined with AM materials producers Constellium, Elementum 3D and Sandvik to establish an industry-led Materials Consortium for AM. The joint effort is designed to make LPBF powder parameters and related testing data for common materials freely and publicly available to end users, enabling increased knowledge sharing and better outcomes as well as faster adoption of AM machines, materials and techniques. The LPBF material parameters support Dyndrite’s LPBF Pro’s extended toolpathing capabilities, including support-free parameter sets.

Research Partners Proficiencies

As part of the research, Dyndrite provides its expertise as a provider of its GPU-accelerated computation engine used to create next-generation digital manufacturing hardware and software. Constellium’s focus lies in the development and manufacturing of high value-added aluminum products and solutions, including Aheadd Aluminum Powders such as CP1 for AM. Meanwhile, Elementum 3D brings its innovation for gas-atomized aluminum alloy AM feedstock powders, while Sandvik is a high-tech engineering group that offers solutions to enhance productivity, profitability and sustainability for the manufacturing, mining and infrastructure industries.

Developing Qualification Protocols

Mimo Technik and Astro spent the last two years developing the “Mastro AM-MCQP-2024: Additive Material Characterization and Qualification Protocol for Production Readiness,” a process for streamlining qualification efforts for the additive industry. This “hyperfast” qualification process involves iterative experiments to determine values for all variables that influence the metal printing process. The parameters are then stored in Dyndrite build recipes for usage. The platform consists of standardized and shareable Mastro Dyndrite build recipes, which are used for parameter development and the Astro testing process.

Mastro-qualified materials are now in production for fracture-critical hardware such as landing gear, propulsion systems, payload structures and defense applications. The Mastro Dyndrite process is the foundation of this protocol and can be explored at www.mastro.vision.

Streamlining Materials and Process Development

The partners say that materials and process development has historically been a long, costly and labor-intensive process. The consortium aims to disrupt this tradition and provide for a more streamlined and cost-effective future for qualifying AM materials and processes for LPBF machines.

“A lack of known, well-tested and flexible printing parameter sets is slowing adoption of additive manufacturing,” says Ravi Shahani Ph.D., Constellium’s AM chief engineer. “Metal 3D users are either limited by materials offered by their OEM or waste an inordinate amount of time and resources developing and requalifying parameter sets, often starting from scratch each time. Working with Dyndrite and Mastro, users can now leverage the transparency of publicly available, tested parameter sets upon which to build.”

Elementum 3D says it has been pleased with the partnership to co-develop parameter sets for its materials. It believes the partnership with the AM Materials Consortium will lead to continued success of developing faster, more reliable parameter sets for materials of the future with production success in mind.

Sandvik is also optimistic about the consortium research. “Sandvik has been producing metal powders for 45 years and LPBF powders for over 20 years, offering the widest selection of alloy powders,” says Luke Harris, sales director for Sandvik’s metal powder business. “Working with our consortium partners, we can democratize AM knowledge, accelerate technology adoption and drive industry innovatIon.”

Dyndrite LPBF Pro is a GPU-powered 3D application that brings power and control to the additive computer-aided manufacturing (CAM), materials and process development process. It enables engineers to develop sophisticated and repeatable toolpathing and manufacturing processes. It also offers advanced tools for process development, including 3D geometric queries to detect and optimize print parameters for difficult-to-print geometric features such as domes, cantilevers and thin walls. Users can also speed build rates, expand available materials, improve part quality and deploy support-free print strategies. The software supports 3D metal printers, including Aconity 3D, EOS, NikonSLM, Renishaw and more.

“We’ve enjoyed working with Mimo Technik and Astro Testing in applying Dyndrite LPBF Pro to the previously manual and laborious world of parameter development,” says Steve Walton, head of Product at Dyndrite. “In powering the Mastro process, we speed the delivery of public metal 3D printing parameter sets to market, opening new opportunities for companies leveraging metal 3D printing for rocketry, aerospace, automotive and numerous other uses. We look forward to working with our materials partners to bring many open parameter sets to market.”

Accelerating Paths to Production

Mimo Technik and Astro are continuing to work with metal powder providers to develop, test and release publicly available LPBF parameters for popular materials.

“Dyndrite has been the perfect partner to address the complexities of collecting significant data for understanding manufacturing with novel superalloys,” says Jonathan Cohen, CEO & co-founder of Mimo Technik. “The journey of bringing a new material into the AM process is fraught with challenges. Recognizing this, our teams embarked on demystifying the process, ensuring that the standardization of testing and data collection — following the development of parameter sets — is straightforward and unambiguous.”

Astro says its goal from the outset has been to streamline the process for organizations to onboard new materials and become production-ready on their machines sooner. “We aim to reduce the iterative process traditionally associated with material qualification, lowering both the time to market and the cost of introducing new parts,” says Humna Khan, Astro CEO and co-founder. By establishing a clear, standardized framework for material characterization and qualification, we are not just facilitating a smoother entry to market but also fostering confidence in the parts produced through AM.”

Related Content

Jeol’s Electron Beam 3D Printer Meets Aerospace Qualification Standard

The company says that meeting the AMS7032 operational qualification standard ensures manufacturers that Jeol’s JAM-5200EBM is capable of producing aerospace-grade material with stable performance and meets all material specification requirements.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreValve Manufacturer Outlines Path to Qualification for Additive Manufactured Pressure Equipment

In this case study, Samson shares how manufacturers can design and produce pressure equipment using additive manufacturing that is compliant with the European Pressure Equipment Directive (PED).

Read More7 Takeaways on 3D Printing As a Pathway to Polymer’s Future

The Cleveland section of SPE hosted “Additive Manufacturing: Printing the Path for the Future” on October 17, 2024. Speakers signaled where AM is and where it is headed with session topics ranging from pellet-based 3D printing to qualification and commercialization of additively manufactured products.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More