Dyndrite SMART Script Automates Generation of 3D Layouts That Adhere to ASTM/ISO Standards

Developers say that automating this process enables manufacturers to achieve approximately 99% labor savings, eliminating human error and accelerating workflows across multiple machines and materials.

Dyndrite’s SMART script automatically generates build layouts in accordance with ASTM/ISO standards. Source: Dyndrite

Dyndrite worked with the ASTM Consortium to develop the Specimen Management via Automated Resource-efficient Techniques (SMART) script which automates how manufacturers create build layouts for characterization and qualification in additive manufacturing (AM).

It is a Python script developed as part of the ASTM’s Consortium for Materials Data and Standardization (CMDS) initiative. Operating through Dyndrite’s programmable laser powder bed fusion (LPBF) Pro software, the SMART script automates the generation of layouts that adhere to ASTM/ISO standards, thereby streamlining an otherwise labor-intensive process.

The SMART script is designed to deliver a comprehensive solution that automatically generates build layouts in accordance with ASTM/ISO standards, including standardized testing coupons, labeling schemas, machine configurations and data management protocols. The company says collective tasks that once took over a week and a half to complete manually using legacy build preparation software can now be accomplished in minutes. Automating these tasks can enable manufacturers to achieve approximately 99% labor savings, eliminate human error and accelerate workflows across multiple machines and materials.

“The ability to automatically drive 3D print build automation that adheres to ASTM/ISO Standards and CMDS best practices marks a major milestone in additive manufacturing,” says Steve Walton, head of product at Dyndrite. “With the SMART script, we’re enabling manufacturers to easily and consistently adhere to layout standards preventing re-derivation of industry rules and objectives, reducing costs to the community and improving confidence in public consortium products — this is how we grow the adoption of additive manufacturing.”

Initially targeting midsized single-laser laser powder bed fusion (LPBF) systems, this script can optimize build layouts codifying part placement rules developed by CMDS. Subsequent iterations of the SMART script will broaden machine selection to include large-format, multilaser machines, as well as other powder bed AM processes such as binder jetting. The script implements the ASTM labeling schema to ensure all specimens are labeled appropriately and generates standardized reports, which drives efficiency in documenting key attributes to ensure high-pedigree data capture across builds.

The benefits of this innovation are said to extend far beyond workflow efficiency. By accelerating the characterization and qualification process, the SMART script can open the door to economically viable production in rigorously regulated industries, such as aerospace, medical and defense.

Dyndrite LPBF Pro is a software solution designed to optimize AM processes with automation and control. Specifically built for LPBF, it enables engineers and materials scientists in highly regulated industries to create scriptable CAD-to-Print automations; conduct complex materials and process development studies; streamline qualification and calibration workflows; and smoothly transition from development to full-scale production. With Dyndrite’s toolpath control, users can print challenging parts — such as thin walls, cantilevers and domes — while codifying knowledge, ensuring repeatable quality and minimizing human error.

“Standards are the backbone of any emerging industry, and in additive manufacturing, they are critical for ensuring quality, safety and consistency across every step of the process,” says Richard Huff, director, Industry Consortium and Partnerships, Global Advanced Manufacturing Division at ASTM International. “By establishing clear guidelines for generating and managing high-pedigree material datasets, CMDS aims to establish the foundations for manufacturers to innovate faster and create a pathway for industries — especially those that are heavily regulated like aerospace and medical — to adopt new technologies with confidence in a faster and less costly manner.”

As automation shapes the future of additive manufacturing, the company says that tools like this can transform how companies innovate and operate by accelerating qualification processes and reducing labor costs.

Related Content

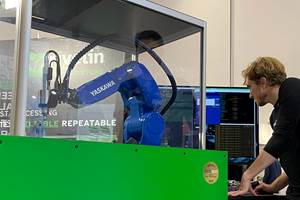

The Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreSavage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More