Recap: The Additive Manufacturing Workshop for Automotive

The inaugural AM Workshop for Automotive at the North American International Auto Show brought together the world’s top automotive and additive manufacturing technology experts on one stage. Here’s what they had to say.

Of all the industries to be disrupted by additive manufacturing (AM), it can be argued that AM’s potential impact on the auto industry is the least understood. The common assumption seems to be that additive’s central role in automotive is for prototyping and small-volume production for motorsports—and that while generative design and lightweighting hold promise for the long term, printing speed and production capacity are years or even decades away from impacting automotive design and manufacturing in meaningful ways.

But to believe these arguments is to ignore the presence and purpose of additive technologies on automotive factory floors around the globe today. Lingering assumptions from only two years ago ignore the intense focus by auto engineers, designers and executives on how to create and deploy new digital workflows that take into account process parameters for generative design, setup for AM and simulation testing necessary for true production of critical parts.

A clearer understanding of additive’s current impact on the automotive industry was on full display during the inaugural Additive Manufacturing Workshop for Automotive (AMWA) at the 2019 North American International Auto Show (NAIAS) in Detroit on January 16. AMWA brought together the world’s top automotive and AM technology executives, designers and engineers to discuss how 3D printing is transforming automotive design and production—not only in the future, but today. In fact, two of the companies that presented at AMWA, Ford and Carbon, used the event to to make a major announcement.

That this event—the first of its kind to be held at the largest auto show in North America—attracted a crowd of hundreds to the atrium stage at Detroit’s Cobo Center was itself a testament to the significance of how automotive OEMs are using additive technologies to advance the auto industry at large. If you missed it, stay tuned to Additive Manufacturing Media for a video recording of the event that will post in the near future. In the meantime, here is a roundup of each of the five presentations from the workshop.

End-Use Parts on Demand with Ford and Carbon: Ellen Lee, Ph.D., Additive Manufacturing Technical Leader, Ford Motor Company; Paul Dilaura, Vice President, Enterprise Partnerships, Carbon

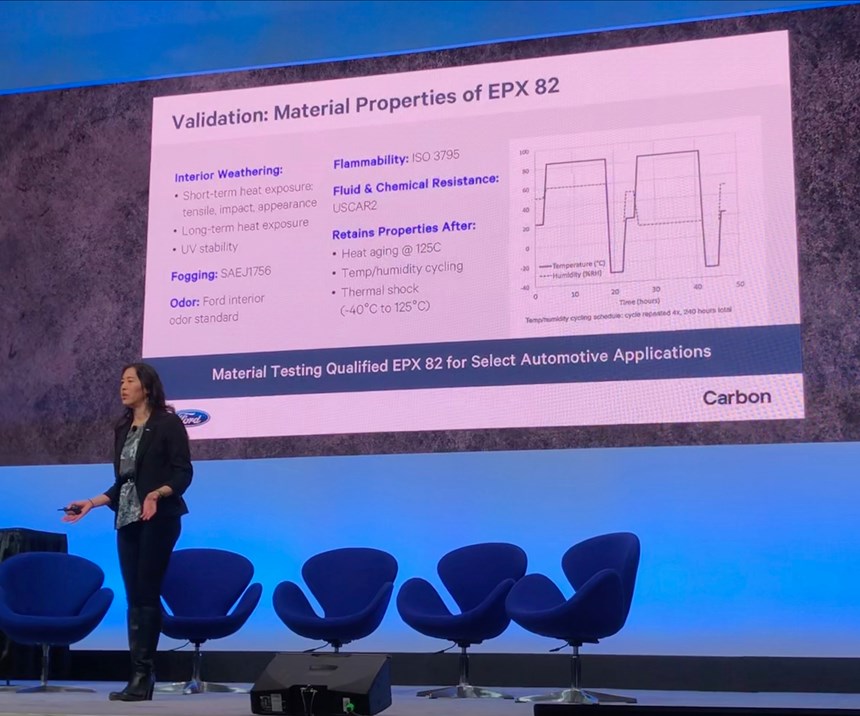

It was fitting that the first presentation for the first Additive Manufacturing Workshop for Automotive broke actual news. Lee and DiLaura used their presentation to showcase the first digitally manufactured polymer parts in production for Ford Motor Company, including a Ford Focus HVAC lever arm (a service component for older models), a Ford F-150 Raptor auxiliary plugs (a niche market part), and Ford Mustang GT500 electric parking brake brackets. The parts, created with Carbon’s digital light synthesis technology using a Ford-qualified epoxy material, exceeded rigorous performance testing and critical requirements such as interior weathering, short- and long-term heat exposures, UV stability, fluid and chemical resistance, flammability and fogging.

Both Lee and DiLaura noted that printing the Ford Focus HVAC lever arm eliminated inventory and warehouse requirements, reduced lead time by 50 percent, and reduced minimum order quantities. Likewise, for the Mustang GT500 electric parking brake bracket, the presenters highlighted a 60 percent weight reduction compared to the previous part manufactured from stamped steel. 3D printing the bracket also simplified the production process through a new design that reduced complexity: The old part used to require two separate components for the right and left sides, whereas the new “mono” design fits both.

Lee and DiLaura ended their presentation looking toward the future of additive’s role in the auto industry. Ford is seeking new sources of value, Lee said: service parts, low-volume production, series production, mass customization and distributed manufacturing. DiLaura said that Carbon is focused on new automotive grade materials, new software and design tools, and end-to-end manufacturing processes that interface with robotics in factories.

From Powder to Part and Beyond – A Holistic Manufacturing Solution: Kevin Brigden, Additive Manufacturing Advanced Concepts, Renishaw

As Bridgen began his presentation, on the screen behind him was an illustrated image of the sun emblazoned with the words “additive manufacturing” across the center. “Additive manufacturing started with pure hype,” he said, as clouds started to appear around the central image. Words such as “use cases,” “generative design,” “material properties” and “process consistency” appeared over the clouds, which eventually overshadowed the sun—and, according to Brigden, the hype of AM. “Now the hype can’t poke through,” he said, referring to technological advances that have allowed additive’s capabilities to summit the hype-curve from just a few years ago.

Leveraging metrology, calibration and performance testing technologies that define Renishaw’s CMM inspection equipment, the company is applying those process foundations to additive manufacturing. Brigden compared Renishaw’s well-established industrial metrology, process control and automation technologies to how Renishaw has approached innovation in the additive space—specifically in Renishaw’s Additive Manufacturing Solution Centers, where Renishaw engineers guide customers from design for AM through process validation to production deployment. Brigden highlighted Renishaw’s four-laser powder-bed metal printer, the RenAM 500Q, and suggested that the greatest opportunity in AM today—which he said Renishaw is pioneering—is in-process control and the ability to capture data during the build process.

Additive Manufactured Mold Tools – An Integrated Manufacturing Approach: Evan Syverson, Additive Manufacturing Business Development Manager, Sodick

While discussing Sodick’s latest hybrid metal 3D printers, the OPM250L and the OPM350L, Syverson used the bulk of his presentation to focus on mold tool applications requiring quick turnaround and short injection cycle times. In fact, Syverson said, throughout the cycle of a plastic part—which includes mold open time, mold closed time, filling stage and packing stage—the biggest time waste is cooling time, which can represent 60 to 70 percent of the entire cycle time. Conformal cooling, he said, offers the greatest opportunity to reduce overall cycle time—a opportunity for which said hybrid manufacturing is particularly well suited.

Sodick’s powder-bed printers combine a 500-W ytterbium laser with a 45,000-rpm linear motor spindle, which can perform milling operations during pauses in the printing process that allow access to internal features that otherwise would be inaccessible when the part is finished. When applied to building conformal cooling channels, this capability allows for the building of printed lines that match the part shape, nearly eliminate hot spots, reduce cooling and cycle time and result in low-to-no deformation when compared to two-dimensional gundrilling. Syverson also pointed out that hybrid manufacturing of molds also reduces the reliance on specialty materials such as beryllium copper, which he said takes 17 percent longer to cool and has a much-reduced tool life.

Industrializing Additive Manufacturing – Design and Produce Useful Parts at Scale: Chris Weber, Director of AM Portfolio Development, Siemens PLM Software; Douglas Ramsey, Chief Development Officer, Hackrod

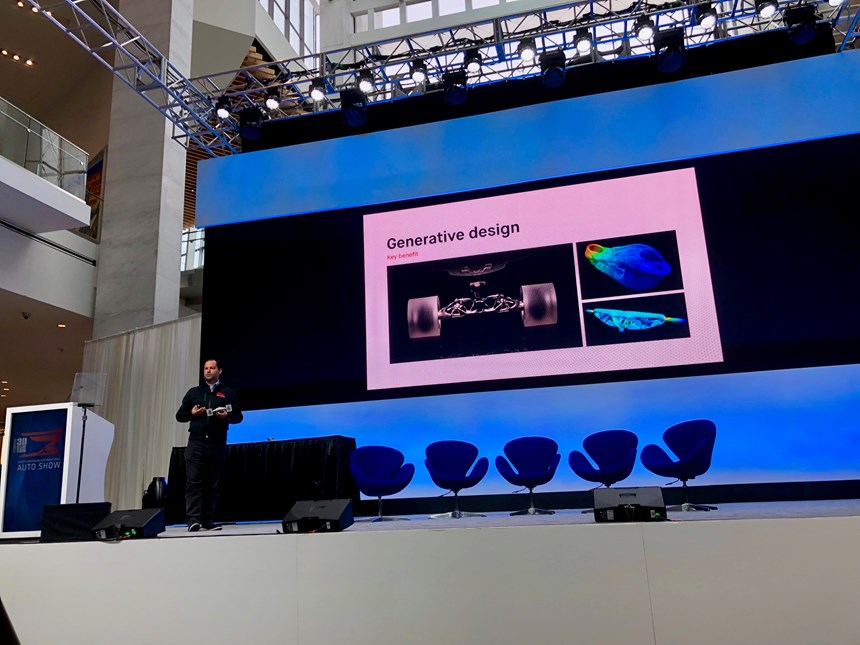

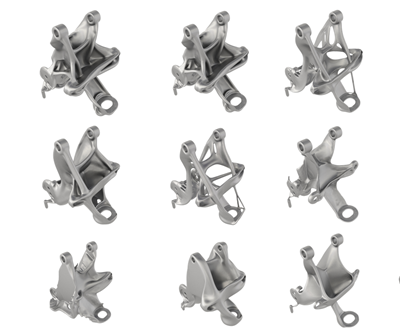

“This is the most exciting time in my career of 30 years,” Weber began. Weber said that while he wasn’t around when they figured out how to stamp metal or CNC a component, the additive manufacturing revolution happening today is equally important. Projected behind Weber as he spoke was a closeup image of the Bugatti Chiron sports car that focused on the “wing active control system”—a hydraulically powered spoiler that helps keep the car on the ground when traveling at speeds up to 240 mph. Weber highlighted aspects of the control system that were reimagined for additive, including the bell crank, the shuttle, carbon-fiber tubes, and attach point brackets. He said that the end result was an “innovation process” that was accelerated tenfold, reduced aerodynamic drag and lightweighted the system by 50 percent.

Hackrod’s Douglas Ramsey took a broader view for his portion of the shared presentation, which began by telling the story of the La Bandita speedster, which Ramsey says is the first car designed in virtual reality with a chassis and other large structural components being 100 percent 3D printed. The company, headed by stuntman and founder of the Bandito Brothers creative studio, is using artificial intelligence and large-scale metal deposition printing to create generatively designed critical components—a process that Ramsey says will someday be achievable “while playing a video game.” “(Manufacturing) is getting back to an artisanal world,” he said. “There’s a convergence of tech coming together around additive manufacturing, generative design, material characterization and machine learning. The engineering knowledge is locked in our heads. I think we're about democratize the information.”

Additive Trends & Technologies in Automotive: Ric Fulop, CEO and Founder, Desktop Metal

While discussing Desktop Metal’s FDM metal 3D printing process for its Studio System, in which the metal is encased in polymer which is removed via heat treatment, Fulop pulled no punches when addressing the challenges and limitations of both traditional manufacturing and powder-bed fusion AM processes. As we approach the 2020s and beyond, he said, the desire for mass customization and lightweighting will increase the ubiquity of generative design. This, in turn, ensures that parts will become too complex to manufacture via traditional methods. Yet the powder-bed fusion process, he argued, has drawbacks that need to be addressed, including slow printing speeds, limited build space, laborious postprocessing, a narrow range of material choices, limited geometrical resolution and limited automation capacities. While Desktop Metal began with its office-friendly Studio System, Fulop noted that shipment of Desktop Metal’s Production System—which employs binder jetting technology rather than FDM—begins in February of 2019.

Panel Discussion

The first Additive Manufacturing Workshop for Automotive ended with a panel discussion with all of the presenters, moderated by Additive Manufacturing Media’s editor-in-chief Peter Zelinski. Visit this page to view the discussion, as well as all presentations (free registration required).

Related Content

From Polymer Tooling to Metal Production Via 3D Printing

As Azoth has adopted new additive manufacturing technologies, its work has transitioned from tooling to production parts for automotive, medical and defense.

Read MoreThis 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreRead Next

Why GM’s Electric Future Is Also an Additive Future

Production capacity isn’t the only reason that additive has been slow to make inroads into the automotive industry. There is a larger barrier to entry—one that General Motors and Autodesk are working to overcome.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreNew Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read More