Brent Donaldson Editor-in-Chief

Brent Donaldson is Editor-in-Chief for Modern Machine Shop, where he is oversees the brand’s writing staff as well as day-to-day management of editorial operations. Brent also serves as a columnist and feature writer and reports regularly about his travels to machine shops, trade shows and conferences around the country and internationally. Brent is also co-host, producer and editor of Modern Machine Shop’s documentary-style podcast, “Made in the USA.”

Before joining Gardner, Brent was editor-in-chief of Northern Kentucky University Magazine — the same university from which he received his journalism degree in 2005. Brent previously served as associate editor for Cincinnati Magazine, and is the recipient of two Ohio Excellence in Journalism awards for feature news writing, Cincinnati Society of Professional Journalists awards, and more than 40 individual awards from the Council for Advancement and Support of Education for writing and editorial.

Fun fact: Brent was the last journalist ever to interview Evel Knievel.

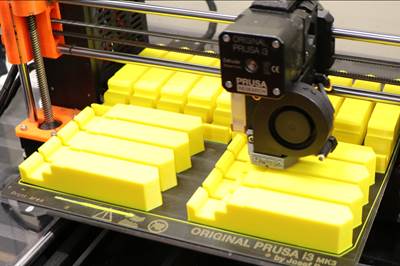

Ford is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read MoreA Resonant Harmony for Bell Casting and 3D Printing

When a 180-year-old bell foundry sought an alternate solution for expensive metal mold patterns, it turned to a 125-year-old company for a modern solution: large-format additive manufacturing.

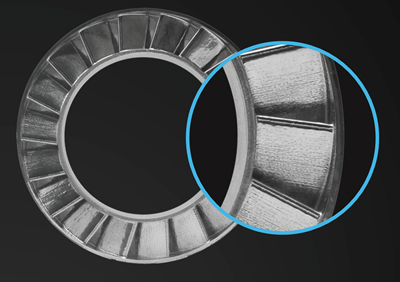

Read MoreSpace Launch System Accumulator is a Giant Leap for 3D Printing

A collaboration between Aerojet Rocketdyne and NASA is resulting in critical parts being 3D printed for new versions of the workhorse RS-25 engine.

Read More10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

Read MoreThe Case for Tackling the Toughest Material First

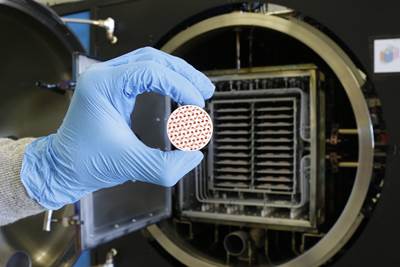

The increasing speed and power of high-end processors and data centers has created a market for advanced thermal management solutions. A Silicon Valley startup called Holo is dedicating its first line of products toward this market, starting with 3D-printed copper heat exchangers.

Read More3D Printing and the Next Giant Leap for Mankind

A collaboration between Aerojet Rocketdyne and NASA is resulting in critical parts being 3D printed for new versions of the workhorse RS-25 engine.

Read More26 Steps Vs. 9: The Metal AM Case for Mission Critical Parts

Knust Godwin introduced metal AM into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

Read MoreInside Oak Ridge’s 3D-Printed Machine Tool Moonshot

The widespread outsourcing of large machine castings led a collaborative team at Oak Ridge National Laboratory to tackle the machine tool supply chain. The first step? 3D print the largest cast component.

Read MoreWhat's the Big Idea in Additive Manufacturing?

A new series presented by Additive Manufacturing Media tackles important themes AM is touching that promise to change manufacturing in a big way.

Read MoreHow a 3D-Printed Metal Ankle Implant Replaces an Entire Bone

Through a novel surgery involving a 3D-printed talus bone, surgeons at the University of Miami found success — and unexpected challenges — with a patient suffering from sickle cell disease.

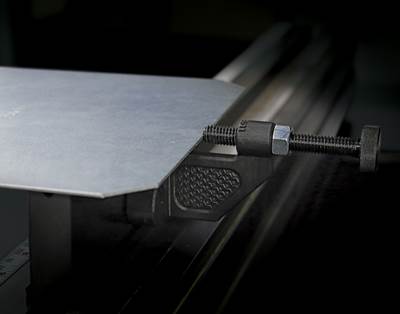

Read MoreA Methodical Strategy to Bring Additive into Sheet Metal Fabrication

When Wilson Tool International launched its additive manufacturing division in 2018, it had already proven 3D printing’s value through dozens of printed parts for its own line of equipment. Demonstrating that value to customers required a new, highly focused approach.

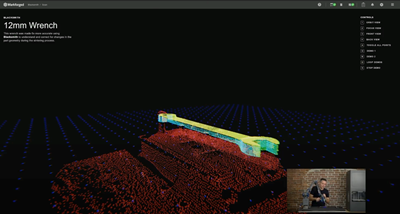

Read MoreAI-Driven Adaptive Manufacturing Software Aims to Self-Correct 3D Printing (Includes Video)

The AI software platform Blacksmith from Markforged shares feedback from its cloud-connected fleet of printers to identify and correct distortions in a 3D-printed part.

Watch