Mold Builder Learns How to Use Hybrid AM to Build Conformal-Cooled Inserts

It is one thing to understand additive manufacturing technology, but it is another to know when to invest, who to partner with and how to sell its value.

When it comes to any new technology, the trick is determining the right time to buy in, and that has been a definite challenge for mold builders looking to invest in additive manufacturing (AM).

“For a while now, everyone has been paying attention to additive technologies. We at Custom Mold & Design (CMD) pay specific attention to the curve of new technologies. What I mean is, there is a point at which a shop can buy into technology too early and at a premium price, which ends up being cost-intensive when the technology supplier develops a better model,” says Vice President Lester Jones.

He also warns against the other end of the investment spectrum; buying technology after it has been commoditized inhibits what the user can charge because it is so readily available.

“We are around it, use it and see the value of it, but we are not a big manufacturer or consumer in the conventional additive manufacturing sense. We have been using 3D printing to make fixtures and prototype parts, and we have been buying additively produced inserts that we injection over-mold for implants,” Jones says.

This Minnesota company considers itself an engineering company that helps people develop products, not just new molds. This mission involves 320 people across three facilities—Custom Mold & Design, Paradigme Engineering and Teamvantage—performing a great deal of ultra-precision part and mold work for implants, surgical tools, pacemaker programmers, diagnostic equipment, hospital bed components and chemotherapy delivery systems. The CMD team focuses on finding creative ways to solve complex problems and AM, specifically hybrid machine technology to produce conformal-cooled inserts, is how they believe they can take advantage of additive technology to make better molds for customers.

The CMD team focuses on finding creative ways to solve complex problems and additive manufacturing, specifically hybrid machine technology to produce conformal-cooled inserts, is how they believe they can take advantage of additive technology to make better molds for customers.

Buying It

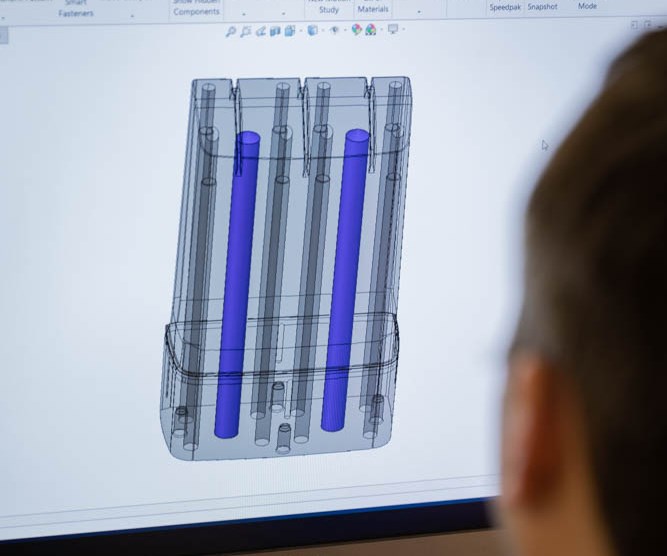

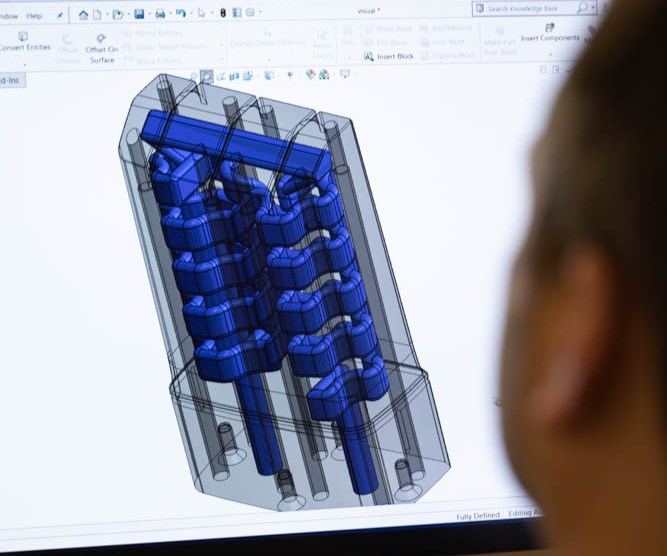

CMD Owner and President Ray Newkirk had his eye on Matsuura’s Lumex Avance-25 machine, which combines powder-bed metal selective laser sintering (SLS) along with high-speed milling in a hybrid platform. This combination of technology in a single platform enables the production of parts and component geometries in a novel way, including conformal cooling features in an injection mold or internal cooling passages in a part.

Newkirk and Jones traveled to Japan to tour Panasonic, which partnered with Matsuura to develop this hybrid process. Panasonic has built hundreds of molds utilizing this practice, and after seeing their operation, Newkirk and Jones felt it was the right time to invest in the technology. It was their belief they would be entering a flatter part of the new technology curve where the likelihood of massive change on the Matsuura equipment was less likely.

“This hybrid machine is on its fifth version, so Matsuura has been doing this for quite a while. They are constantly making improvements but more on the software side now,” Jones says.

But more importantly, it was the partnership. “We created a relationship with Matsuura whose goal is not to manufacture product for people (outside of testing to demonstrate the equipment) but to sell the equipment,” Jones says. With that in mind, CMD came to an agreement that if Matsuura identified contract manufacturing work to make inserts on the Lumex, CMD would manufacture them. “This agreement helped push us along in our decision to invest. We believed this was a real opportunity to partner with Matsuura and turn this into something special.”

CMD is also in a unique location in Minneapolis/St. Paul, which is also home to Matsuura’s national headquarters. Matsuura has a showroom for its AM technology, but they were looking for a partner to showcase the technology in a real environment. And having the Lumex amidst CMD’s other highly precise machine technology, like its nine Yasda machine tools, does not hurt either. “We are doing real stuff with the technology onsite instead of making pretty trinkets,” Jones says.

“Compared to conventional post process cooling pipes, those created on the Lumex are more efficient at cooling. Companies have seen improvements of up to 30 percent in cooling effectiveness with up to 40 percent reduction in cooling time. This is what we like to call the ‘magic’ of conformal cooling,” Jones says.

Learning It

Another curve of technology is the learning curve, and AM has a tremendous one, according to Jones. “You need to embrace the unknown and accept a temporary lower level of efficiency to achieve success," he says. “You cannot underestimate how big of a step it is to move to additive technology or how much it is going to cost in terms of money and time for people to learn it,” Jones says.

He explains that this step means taking someone proficient at a job and placing him or her where they are going to struggle for a little while. As the workload increases, it may seem counter-productive, but you need to stick with it. The CMD team knew that if they did not push through it, they would never figure it out, and their goal is to be an expert in this arena.

However, another real advantage for CMD is the family of companies it operates within, which includes contract manufacturer Teamvantage and mold builder Paradigme Engineering. “We can take lessons from making a part and then producing an insert for a tool, running it in a mold, and testing it, all in house,” Jones says.

A true partnership also comes into play with new technology. “By learning and working together, you both get smarter,” Jones says. CMD is Matsuura’s local partner in offering contract Matsuura production and in the application of the Matsuura Lumex technology for the mold industry. However, this role is not new to the organization. The company has worked through this type of learning process with its plastic injection molding machines, for example. It has a similar partnership with Sodick Plustech, who did not have much equipment in operation in the United States when Teamvantage purchased its first Sodick press. The organization learned how to help the technology supplier grow and expand so that Sodick Plustech could better support them.

As CMD identifies issues with the hybrid technology, Matsuura is quick to develop solutions and is committed to keeping the machine current. Matsuura focuses on serving the mold manufacturing industry with these machines, so they work closely with mold builders to continually develop machine technology. As such, they acknowledge that mold builders consider certain aspects of the process that they would not consider themselves.

Mold builders think about the process from a practical standpoint because they are performing mold work all day, every day, whereas a machine tool builder would not naturally think that way.

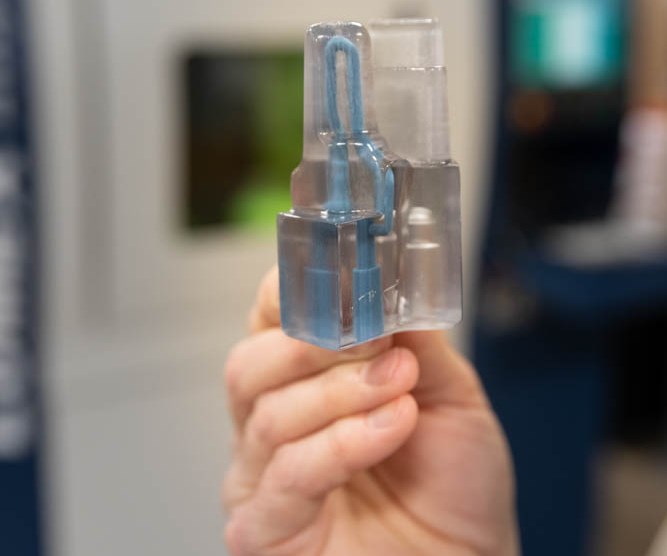

“For example, the base of the mold insert, where mounting holes and water inlet and outlets, are can be easily produced conventionally,” Jones says. “This can then be used as the build plate with the laser sintered material added on top for the detailed molding surfaces with conformal cooling lines created inside the block.”

“Because we build high-end molds with tighter tolerances, we are zeroing in on all the process parameters that impact accuracy and nailing that down to where we can be a lot more consistent and precise,” Jones says. “We are going to ask questions that Matsuura might not have ever thought of, which could help them improve their machine technology and, in the end, sell it to other mold builders,” Jones says.

Using It

Often referred to as a “one machine, one process” system, the Matsuura Lumex series permits production of the most complex and challenging parts by combining both high-speed milling and laser sintering capability. The system produces highly accurate parts from metal powders that are sintered using a laser while surfaces are precisely milled at high speeds.

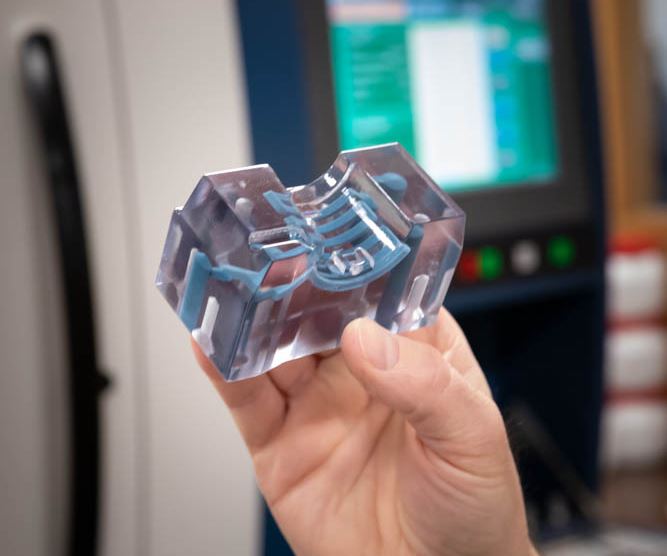

Matsuura’s Lumex is an extremely effective method of creating conformal-cooled injection mold inserts. Inserts traditionally produced through machining and EDM contain straight cooling paths whereas conformal-cooled inserts produced with this hybrid process incorporate complex curved, shaped or spiral cooling channels. On top of that, this process easily forms the channels in small, narrow or awkwardly shaped inserts.

“Compared to conventional post process cooling pipes, those created on the Lumex are more efficient at cooling. Companies have seen improvements of up to 30 percent in cooling effectiveness with up to 40 percent reduction in cooling time. This is what we like to call the ‘magic’ of conformal cooling,” Jones says.

The benefits to the owner of the mold are clear to Jones:

- Improved cycle times, sometimes as much as 50 percent using conformal cooling

- Improved part yields and enhanced quality

- Shot-to-shot consistency and repeatability

- Lower cavitation for high-volume production parts, with a consistent molding cycle (which is 33-50 percent faster than without conformal cooling)

- Improved injection molding machine usage with faster cycles

The result is a new generation of molds with consistent and accurate cooling across the entire forming area, even within small or complex shaped pockets. This technology also eliminates many of the distortion and poor part quality problems that are traditionally associated with inefficient cooling.

Today, Custom Mold & Design has been working with the Lumex equipment for a little less than six months. Time has been spent training with Matsuura’s application engineers, building parts on their own, and now they are experimenting with other ways to use the equipment to establish the limits of the process. There is a lot of collaboration going on between Matsuura engineers, Custom Mold & Design’s personnel and customers who are looking for the utmost efficiency in the injection molds they buy.

Selling It

CMD is big on selling the total cost, believing mold builders need to recognize when they have a better mousetrap and then be proud of the fact that it is a better total value for the customer. The most important consideration is the length of time a mold is going to run and remain trouble-free. Cycle time is a significant part of that, and AM can help CMD produce molds that run faster, saving customers money. CMD’s approach is to educate customers on the long-term value of a conformal-cooled insert to further justify the purchase of a more expensive mold.

“If a shop can build a mold that cycles at 85 percent of the cycle time previously, then they need to do the math and determine what that 15 percent is worth,” Jones says.

CMD truly understands the benefits of 3D-printed, conformal-cooled inserts because their sister company, Teamvantage, quotes plastic parts all day, every day. This competency gives the company an advantage in terms of selling the true cost of an additively produced insert. They are even creating a white paper that shares some of the costing information to more effectively demonstrate the payback period of the mold investment, as a result of reduced cycle time.

However, many times the decision boils down to having the right customer. The right customer will be looking for opportunities to reduce overall costs, not just reduce their supplier’s margins. “If your customer is a purchasing agent who only compares the acquisition price of each mold and does not consider the warranty, mold material or number of actions then he or she will never understand the true cost of the mold over its lifetime. They are never going to buy this premium priced product because they do not understand how to value it. We have many examples of tools that run many millions of cycles, and if the customer does not value that, then we are talking to the wrong people,” Jones says.

To help sell that more expensive, conformal-cooled mold, simulation software to model and prove out all scenarios is key. Typically, moldmakers tend to design conformal cooling channels using gut-feel. However, today’s advanced software does a much better job of designing those systems, predicting efficiency and identifying areas that a mold builder may overlook when using a gut-feel approach. Currently, CMD contracts out the cooling simulation portion of the mold design. The team is still getting to know the additive piece of the puzzle, but they know the next step from a software standpoint is to roll in the analytical segment.

CMD is also tackling some warpage issues with AM. The shop wants to improve tolerances, but warp is a limiting factor, so anything that they can do to reduce warp will allow CMD to pursue more challenging parts. “Because we build high-end molds with tighter tolerances, we are zeroing in on all the process parameters that impact accuracy and nailing that down to where we can be a lot more consistent and precise,” Jones says.

Success to Custom Mold & Design is a satisfied customer, which means a mold that runs faster, and with this additive technology, customers can have a mold that runs 20 percent faster than a mold manufactured using conventional methods.

Growing It

Mold builders are good at coming up with creative ways to use equipment. “We are always looking for how we can take technology and apply it to a different problem. We are problem-solvers. We want people to come forward with concerns or issues, and we will try to come up with solutions,” Jones says. And additive manufacturing technology is no different.

However, the CMD team is also conservative by nature. They are only committing to what they know they can do, which means that they are prepared to walk away from work they determine too risky. They need a series of successes, so they are trying to be smart about the projects they take on. They want to make sure that they are slowly building up an installed base of molds running successfully, rather than having some catastrophic failures.

Success to Custom Mold & Design is a satisfied customer, which means a mold that runs faster. With this additive technology, customers can have a mold that runs 20 percent faster than a mold manufactured using conventional methods.

“We set the Lumex machine in the facility in a way that we can have a second one next to it. We hope that we find ourselves busy months or a year down the road needing to add another machine. Then we will know we have been successful!” Jones says.

Related Content

JuggerBot 3D Chooses Research Partners for Air Force Large-Format Hybrid Additive Manufacturing Project

Oak Ridge National Laboratory and Mississippi State University’s Advanced Composite Institute have been selected to assist in the research and technical development of production workflows using thermoplastic and thermoset deposition.

Read MoreVideo: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreSidus Space Successfully Launches LizzieSat Hybrid 3D-Printed Satellite

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Steps up in Size

The bigger size of this combination milling/laser-metal-sintering machine could enable it to enter new markets.

Read MoreListen: Podcast Discusses Trends, Benefits of Metal AM for Moldmaking

An episode of the Manufacturing Alliance podcast recorded live at NPE2018 features industry experts discussing who benefits from using additive manufacturing in moldmaking and which AM trends are helping moldmakers.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More