Christina Fuges Editorial Director

Christina M. Fuges has 28 years of experience in trade publishing. She has been MMT’s Editorial Director for the past 25 years. She was a founding partner of Communication Technologies, Inc. (CTI), which launched the publication and its annual trade show, the MoldMaking Expo (now Amerimold expo).

She also was editorial director for CTI’s three other trade publications: Time-Compression Technologies, Continuity Insights and Emergency Number Professional.

MMT was acquired by Gardner Business Media in 2004 where she continues to serve as the brand’s Editorial Director.

Christina is also the Technical Conference Director for the annual Amerimold expo and was a contributing editor for Additive Manufacturing focused on mold and toolmaking applications.

Prior to MMT, Christina was with Witter Publishing as Managing Editor for two critical cleaning publications: Precision Cleaning and Parts Cleaning magazines.

Christina’s passion is building community within the audiences her publications serve by providing relevant print, digital and conference content focused on technology and business issues, while working cooperatively with technology suppliers, mold builders, industry associations and educational facilities.

She was secretary for the Society of Plastics Engineers Mold Technologies Division for five years to help foster growth in the moldmaking and design profession by encouraging the training of moldmakers at the apprentice level, supporting the continuing development of established moldmakers, and by gathering and exchanging information on materials and mold performance.

Christina also works with other moldmaking trade associations, such as the American Mold Builders Association and PLASTICS, on special projects such as the MoldMaking Matters educational video series.

Christina moderates panels and speaks at industry trade events on workforce development, mold manufacturing, and the brand’s annual Leadtime Leaders Awards program.

Christina uses various media outlets to help educate her audience, including industrial video projects that highlight shop innovations, and guest spots on IMTSTV for IMTS, and Plastics TV on the NPE Network to discuss moldmaking trends and technology.

Most recently, she hosts MMT Chats—quick casual but insightful video conversations with leading mold builders. She has also co-hosted The Manufacturing Alliance podcast onsite at mold-building facilities and trade shows to spotlight mold builders across the country. Kula Partners interviewed Christina for their Kula Ring podcast on how she uses podcasts to share stories and personal connections to break down the brand barrier. She was also a guest on The WAM Podcast to talk about the origin of MMT and her journey as a woman working within the mold manufacturing industry.

Christina received her bachelor’s degree in telecommunications from Wilkes University in Wilkes-Barre, Pennsylvania.

Christina lives outside of Philadelphia with her husband and son who are all active within their church, school and the local community. When she’s not working, she spends time raising awareness for Williams Syndrome, which is a genetic disorder her son has. Christina also enjoys being outdoors, day-hiking, fast-walking, cruising back roads in her Jeep, binge-watching original Netflix series, and planning family events. She loves music, the sun, and relaxing by the water or on a beach.

MoldMaking Conference Session Spotlight: 3D Printing

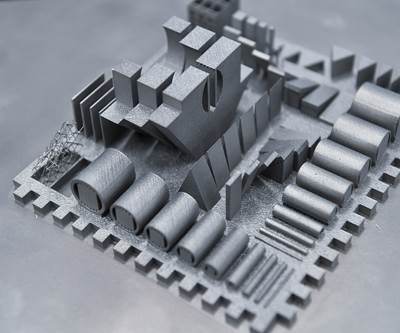

Want to learn about hybrid tooling inserts or the current state of 3D metal printing?

Read MorePVD Coatings Solve Common 3D-Printed Mold and Part Problems

The right surface modification solution can alleviate a few common additive manufacturing pain points that typically require creating new molds or parts.

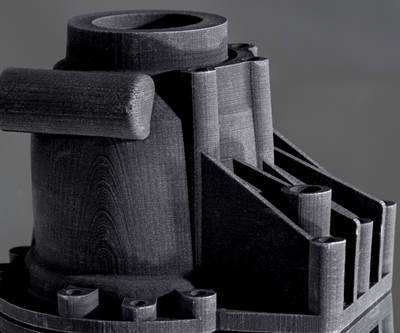

Read MoreBuilding Confidence in Additive Manufacturing for Tooling

New potential for mold tooling applications is reached with custom-designed materials for additive manufacturing.

Read MoreMold Builder Learns How to Use Hybrid AM to Build Conformal-Cooled Inserts

It is one thing to understand additive manufacturing technology, but it is another to know when to invest, who to partner with and how to sell its value.

Read More3 Ways a Small Mold Builder Uses 3D Printing

How mold builder Byrne Tool + Design uses 3D printing for simultaneous mold manufacturing, conformal cooling and hybrid designs.

Read MoreHow to Calculate the Full Cost of Additive Manufacturing Versus Injection Molding

A true evaluation of additive includes a look at materials, speed, quality, scalability and cost. Bruce Bradshaw of Evolve Additive Solutions explains how to evaluate AM in an injection molding environment in terms of these 5 factors.

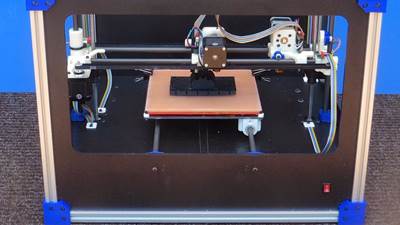

Read MoreWhen Is 3D Printing Cost Effective?

Hype continues to surround additive manufacturing. These three factors can help determine whether a part is worth 3D printing.

Read MoreRoush Uses Engine Cylinder Head to Prove Out Additive Manufacturing

A 3D-printed cylinder head investigation reveals the possibilities of additive manufacturing.

Read MoreAccepting the AM Revolution at Baker Industries

Making a case for additive manufacturing integration whenever it makes sense is the standard at Baker Industries.

Read MoreLinear AMS Returns, Retooled and Refocused

After splitting with Moog, the company is getting back to mold tooling and homing in on low-volume plastic part production.

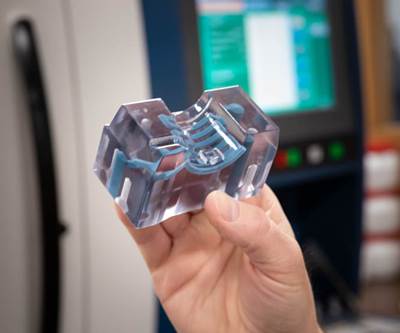

WatchThe Right Design, Material and Machine Combination Takes the Risk Out of 3D Printing Molds

Full-service design and mold delivery, moldmaking materials, and a low-cost, high-precision printer minimize the technical risk of 3D-printed mold tryout.

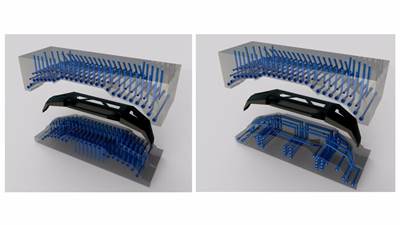

Read More3D Robotic Deposition Advances Conformal Cooling

A new conformal cooling technique has emerged, rooted in a multilayer robotic deposition technology that is capable of manufacturing near-net shape objects.

Read More