In Coronavirus Uncertainty, 3D Printing Is a Potential Solution for U.S. Manufacturing

The impact of the COVID-19 virus has reached U.S. manufacturers by way of the supply chain. Here are several ways 3D printing could help, plus a video discussion of the data with economist Michael Guckes.

If you source materials, parts or products from Asia, chances are your business is or will soon be impacted by the coronavirus. Since the first case was reported in Wuhan in December 2019, the virus has spread to at least 40 countries and claimed more than 3,000 lives. Millions of people remain under lockdown in China’s Hubei province, and it could be weeks or months before life returns to normal for areas affected.

(Are you a U.S. 3D printing company that has been affected by coronavirus? Tell us your story and hear from others.)

Welcome! You’ve unlocked premium content.

On the industrial front, China’s factories are reopening, but February’s purchasing manager’s index (PMI) shows that production and new orders are down; normal production is not expected to resume until at least mid-March. Meanwhile, shipping of goods and materials has slowed considerably. On February 27, The New York Times reported more idled container ships than during the global economic crisis in terms of tonnage. With airlines canceling flights in and out of the country, the opportunities to move freight by air have been reduced as well.

The situation in China is beginning to have a ripple effect on manufacturing supply chains leading to other parts of the world. Many U.S. companies are already feeling some impact. In a survey of composites industry professionals in the United States conducted by Gardner Intelligence (research arm of our publisher Gardner Business Media) and sister publication CompositesWorld, nearly 60% reported some level of impact on procuring parts and materials just 12 weeks after the first reported case of illness.

Anecdotally, I and my colleagues have heard about OEMs that can no longer get parts and materials from China reliably. Retrieving necessary tooling such as injection molds for the purpose of moving production elsewhere is equally, if not more, difficult. In the United States, 3D printing service bureaus and other manufacturers are fielding questions from existing clients anxious about their supply chains, as well as queries from potential new ones looking for alternative suppliers. If the supply chain for raw materials is disrupted by COVID-19, even U.S. contractors with manufacturing capacity could reach a point where filling orders is difficult or no longer possible.

All told, the slowdown in shipping may be the thing to have the most lasting impact on U.S. manufacturers and their customers.

All told, the slowdown in shipping may be the thing to have the most lasting impact on U.S. manufacturers and their customers. The issue is not confined to current shortages; when China’s ports eventually return to full capacity, the shipping industry will have to deal with a significant backlog of freight that will stretch delays even further.

Despite the challenges, the situation also presents a few silver linings for U.S. manufacturing. Here are three potential strategies for coping right now that could have an impact extended beyond that of the coronavirus:

1. Rethink the manufacturing process for needed parts.

The resources needed to make an injection molded part are the raw material and the tool. If completed parts cannot be transported and the mold is now inaccessible, one option might be to change how that part is made to make it possible to produce in the U.S. A 3D printer needs only the raw material and the part file, no tooling required. A component designed for a conventional process may not be reproducible as-is, but reworking a design for 3D printing may result in additional benefits like assembly consolidation and lightweighting. This may be a good time to explore additive manufacturing and potentially redesign an existing part, product or assembly.

2. Consider stop-gap measures.

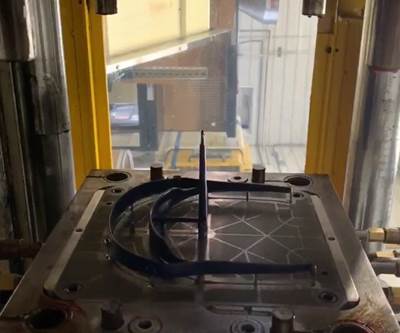

If a mold is absolutely necessary, 3D printing could be a fast way to build a replacement in the U.S. and reshore manufacturing. We’ve reported on a number of companies that make injection mold tooling using metal 3D printing, but it’s also possible to 3D print plastic and composite molds suitable for short runs. Recreating tooling this way (or printing some parts directly) could help manufacturers bridge potential production gaps.

3. Start building a disaster recovery plan now.

Even if your business hasn’t been affected, the spread of coronavirus is a good reminder to plan ahead. Identify the weak points in your supply chain, and create strategies to mitigate them. “De-risk” operations where practical, perhaps by reshoring production or distributing it among more than one location. Digitize as much as possible for flexibility in a future crisis. Build up a network of backup suppliers before you need them. (We have a directory of service providers that could help. And if you provide 3D printing services, reach out to be listed.)

Video: What the Data Shows

I sat down with Michael Guckes, chief economist for Gardner Intelligence, to talk about the impact that coronavirus is having on manufacturing. Our discussion in the video below includes analysis of China’s PMI for February, as well as data from additive manufacturing companies based primarily in the U.S. (drawn from AM’s print readership). While created with an AM audience in mind, the information is relevant to U.S. manufacturers regardless of current 3D printing usage. Watch here:

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreVelo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreThis Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreRead Next

6 Reasons to Use Plastic 3D Printing

Smaller batches and shorter lead times are just two of the benefits of 3D printing parts in plastic. Here are six reasons to choose polymer additive manufacturing (with examples).

Read More3D Printing and Coronavirus: U.S. Additive Manufacturers Share Their Experiences

The COVID-19 outbreak has brought both setbacks and opportunities for American manufacturing. 3D printing companies share their stories.

Read More

.jpg;width=70;height=70;mode=crop)