3D Printing and Coronavirus Check-In - Week of 4/13/2020

In this week's update we discuss how additive manufacturing is supporting injection molding for masks, and ramping up to production quantities of face shields and testing swabs.

As the pandemic continues, we are beginning to see a greater emphasis on scale production for needed healthcare items in the United States. 3D printing is still the main production technology for face shield visors, but is also being used as a tooling solution in at least once instance to support the manufacture of masks.

In this fourth weekly video, we discuss 3D printed mold tooling; high-productivity 3D printing of face shield visors; an adapter model for reusable face shields using hard hats; and 3D printed swabs, perhaps the most important production story for additive manufacturing — and coronavirus treatment — right now.

Resources and links

- Last week’s 3D Printing and Coronavirus Check-In

- Keselowski Advanced Manufacturing 3D prints an aluminum mold in 48 hours

- Avid Product Development’s face shield design

- GE Additive 3D prints hard hat face shield adapters for TriHealth

- PrintedSwabs.org

-

Injection Mold or 3D Print? How Resolution Medical Pivots Production

Transcript

Peter Zelinski

I’m Pete Zelinski with Additive Manufacturing dot Media.

Stephanie Hendrixson

I’m Stephanie Hendrixson, also with Additive Manufacturing dot Media.

Peter Zelinski

The health emergency of the COVID-19 crisis brought on a manufacturing emergency, and additive manufacturing led the charge. Stephanie, you and I cover additive manufacturing. In normal times, we have a YouTube series devoted to additive manufactured parts. And in this COVID crisis, in the space where it meets with additive manufacturing, we decided that this this weekly video check-in, kind of rough, is our best way to sort of get a handle on process, contextualize, summarize, everything that's happening, and it's all happening quickly.

Stephanie Hendrixson

That's right. And so we've been doing this, this is our fourth video, and we're starting to see some different kinds of trends emerging. So last week, we talked about this pivot to production where we're seeing manufacturers, not just additive manufacturers, but manufacturing in general kind of changing course and starting to make production quantities of PPE, ventilator parts, things like that. So Pete, I think you have a couple of updates there on that front.

Peter Zelinski

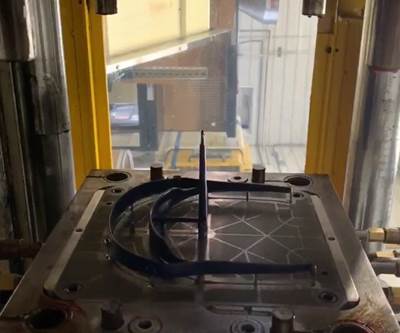

Yeah, I do have a couple examples of that happening. We talked about, you know, 3D printing was the first out of the gate, but we talked about 3D printing, sort of passing the baton to conventional processes like molding that can achieve higher production rates. Well, 3D printing still potentially has a role there. So here's an example from Keselowski Advanced Manufacturing, KAM in North Carolina. They do metal part production through both machining and additive manufacturing. They have both capabilities. And a mold came recently for a mass design developed for this crisis, and a mold that would typically be milled.

But the the KAM team looked at it and realized in this case, metal 3D printing would do it faster. In the case of this particular mold, there's no really tight tolerances. And KAM already had some parameters worked out on their SLM Solutions additive manufacturing machine for achieving really fast build rates when they needed to. So they 3D printed an entire metal mold in five hours.

Stephanie Hendrixson

So that's really interesting. You know, I think we sort of started talking about that last week, but additive shifting maybe from being the production technology to being the tooling technology to support higher and higher quantities.

Peter Zelinski

Yeah, and choosing what the right process is, that decision is sort of looking more and more like the way the decision is made in conventional manufacturing. Sometimes, Brad Keselowski, he's the founder of the business, and he talked to me a little bit about that about what this shows. You know, like manufacturing lead times, they're not carved in stone. It's just that in normal times, you have lots of work all at once competing for the same equipment. And you've got a workflow and a way of doing of doing different kinds of parts, different kinds of tooling depending on what's demanded. But in an extreme situation, like what we're facing more and more of these recent weeks, in an extreme situation, it's possible to look at the problem in an entirely different way and get the part out the door much faster than you think. So single day turnaround on an injection mold, like that is not at all common, but under the right circumstances, it's doable.

Stephanie Hendrixson

Okay, so that's 3D printing used as the support technology for making the mold. Do we have any good production examples where 3D printing is the manufacturing technology?

Peter Zelinski

Yeah, I've got an example of that, personal protective equipment: face shields. We've been talking a lot about face shields. I spoke with Kyle Harvey at Extol Incorporated in Western Michigan to get a sense of rates and quantities. He's in production scale additive manufacturing, what that now looks like. So Excel uses HP’s Multi Jet Fusion 3D printing technology. So again, this is this is industrial manufacturing, 3D printing for production quantities, and HP has kind of organized its users of this technology around this COVID challenge.

There's another HP user, Avid Product Development, that developed a design for the face shield headband, but also a design for the nesting within the additive build in the HP machine. And Extol and other HP users now have access to this. You get about 290 headbands per build out of this nesting. And on Extol’s machines they can do about a build and a half per day.

Another thing HP has done is they've locked in a supplier for the clear plastic that completes the face shield. So what all that means together is that Extol is capable of on each one of its machines producing about 450 face shields per day. And that is pretty sizable quantities compared to some of the very first 3D printers that were able to engage in this work.

You know, face shields in particular continue to move ahead. And Stephanie, I know you found an example of a different idea and how to solve the facial problem.

Stephanie Hendrixson

Yeah, so this is this is an interesting story. It's actually a local story. So we should say we are filming this right now from different places in Cincinnati, Ohio. And this story is actually about the TriHealth hospital system here in Ohio. So, yesterday I talked to Mike Waterman who is the director of lean for TriHealth, and he leads the process improvement team for the hospital system and they are responsible for basically just implementing lean procedures throughout the hospitals. So everything from making sure patients are getting their meals delivered on time to standardizing the way that surgeons lay out their tools in the operating room.

Of course, right now a lot of what they're focused on is trying to make sure that they have the items in stock that they need. And one of the areas of need that they identified was face shields. So as we've talked about before, the face shields allow you to extend the lifespan of an N95 mask by providing an another layer of protection. And so they identified this as an area of need, they actually went so far as to buy some face shields from Grainger, the industrial supply company. But they could only buy the shield part; they actually couldn't get the headbands. So they ended up connecting with GE Additive which is also based here in Cincinnati to see if they could get some of those, like the visor piece printed that they could attach this existing shield to.

But when Mike actually went there to have a meeting and bring them some of these shields, in the room where they met, there was a hard hat sitting there. And so somebody grabbed that and thought and said, you know, well, instead of printing the entire visor, what if we figured out a way to attach these shields to something like a hard hat? And it turns out that hard hats universally have these these slots around around the brim where you can attach accessories. What they ended up doing instead was creating this design for an adapter basically, that allows you to attach an existing visor on to a hard hat and it sort of is like a hinge so you can lift the visor as you need to.

From a manufacturing perspective, this makes a lot of sense. You're using some off-the-shelf components and you're just printing the small pieces that you need to connect them together. These adapters are much smaller than a full visor would be so you can make more of them more quickly. You're not using quite as much material,

But the hospital really likes the solution for a couple of reasons. So some of the earlier visor designs we saw were critiqued because they left the top part of the shield open, and so conceivably some sort of aerosol could get up and behind the shield. With a hard hat, you have that brim there so that's kind of blocking that that area of access.

But the other thing they really like about this is that the hard hat solution is reusable. With a lot of the other visors that are out there, they're either single-use, they're disposable, or maybe you can get like a week's worth of use out of them if you're wiping them down and making sure that the same person is always using the same visor for that whole week. But that introduces difficulties with storage and cleaning it as well as you can.

With the hard hat solution, every part of this — the face shield, the hard hat, the adapters — every part of this face shield solution can go into the existing sterilization process the hospital uses for surgical instruments and other things. And so at the end of a shift, they can just collect all of the hard hats, sterilize them all. And then the next day or the next shift, it doesn't matter who's wearing which hardhat they're all going to be clean and safe to use.

And so I think that kind of speaks to a larger trend that we're seeing right now. You know, we're learning a lot about how to design and clean PPE. And it could be the case that as we come out of this pandemic, that's that might be one of the things that sticks, we see more and more reusable solutions for healthcare providers.

But for right now, Mike Waterman and his team, they are really focused on the existing stock of PPE that they have. They're very closely following the forecasts to try and figure out how many patients they could be expected to see, and whether they're going to have the supplies that they need and whether they might need to be ordering more.

Peter Zelinski

Boy, a couple things to react to there. So the idea that the top of the head is covered, like everything's trade offs, right? And we saw that in different PPE headband designs. We've spoken in earlier versions of this video about how different hospital systems seem to have different preferences about what they're willing to accept. And that trade off is, does the headpiece protect the top of the head? Because eliminating that top of the head protection allows a quicker build time and faster production rate. But now this idea that you found at TriHealth completely short circuits that trade off all together.

I guess the other thing I picked up out of that is this idea of they're looking at their existing stocks. They're kind of looking at what this new idea gives them, how much it stretches what they have. Back to Extol and what they're experiencing. So they've reached out to hospitals all around them, let them know that they have this capacity, let them know that they can go in to production for 3D printed PPE and have gotten a lot of interest in that. But so far, it's just interest. It's just the mode of sort of standby. What's becoming clear is the hospitals just really don't know what's coming. They have standard PPE now, but they're aware they have a finite supply and they don't know how long it's going to last them. And some of their existing sources of supply are starting to ramp up and become part of the solution, maybe all the solution. It's sort of it's not yet clear how much this production quantity PPE that 3D printing could provide, is going to come into play.

Extol actually invented another product for first responders for firefighters. One of their employees is also a firefighter and help them invent a cap for the self contained breathing apparatus that firefighters use, a cap that holds a filter and turns it into a filtered mask. But again, it's the same situation with fire departments. First responders all over the country, according to Extol, are ordering one or two of these and really interested and might be getting ready to place larger orders if their current PPE stocks start to look dangerously low. It's just not clear yet to what extent that's going to happen. But maybe that brings us around to what I think might be the biggest production story to come from this crisis. You teed it up last week, Stephanie, I'm referring to testing swabs, which are now being 3D printed in large quantities. Have you learned more about swabs?

Stephanie Hendrixson

Yeah, so I do have an update there. I think first we should just take a moment to say why these swabs are so important. So these are part of the testing kits that healthcare providers are using to determine if patients have COVID-19, which is really, really important right now, as we're trying to, you know, flatten the curve, we need to be able to track how many cases are out there to see what the trends are. And then as the country starts to open back up, we're going to need to be able to test patients very quickly to contain any future outbreaks or cases. And so right now, the swabs are really kind of the bottleneck in this process.

So the way that they work, these swabs are six to seven inches long. There are a couple of different types of there are there are nasal swabs there are throat swabs, but the ones that are the most reliable are nasopharyngeal swabs, or NP swabs, which go through the patient's nose to kind of the back of the throat and they are usually flocked with cotton or nylon or something like that. But the the 3D printed solutions that we're seeing right now, they're all one piece. So it's it's kind of simplifying the manufacturing because it's all one material.

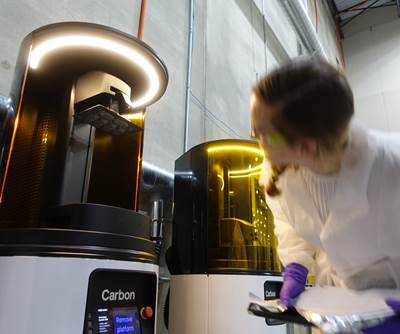

There were a couple of different effort to design these to start getting them tested, and now this week now there is this consortium of companies. You can go to Printed Swabs dot Org and learn more. But it's basically Origin, Carbon, Envisiontec, and Formlabs, who are all kind of coordinating their efforts to 3D print these different swabs. And so I actually talked to one of the companies that's been involved—one of the manufacturers who's been involved: Shawn Patterson at Resolution Medical. They have six Carbon printers there, and they are an FDA registered facility, which is what you need to be to be making these swabs. And so they have sort of taken the lead on Carbon’s efforts as sort of the quality control hub and the shipping hub.

Carbon has mobilized Resolution Medical and a lot of the dental labs that use its printers and some other manufacturers to make these swabs because actually the material that they're using is a resin that is typically used to make mouth guards and some other dental devices. So it's got a little bit of flex to it, but it's biocompatible, it's safe for applications like this.

And so these dental labs and these other facilities are making swabs. They send them to Resolution Medical, who is then validating and and inspecting everything as it comes in. And they're the ones now that are doing the packaging and the labeling and the shipping. They're doing all of the packaging right now by hand and they're in the process of getting some automated equipment to help speed that process up. Between the swabs that they themselves are printing and the ones that they are receiving from these other facilities, they are ramping up to be shipping about a million swabs every week. So yeah, definitely production quantities here.

Peter Zelinski

In talking to Resolution, did you get any sense of what that production is like for them or how it's playing out for them? They've been a medical manufacturer all along. They were doing production quantities, but not quantities like this. What's it like for them?

Stephanie Hendrixson

So actually, Shawn said that a lot of their regular production is still happening. So they do make medical devices that are still in demand. And so this is something, this is sort of a project that they've taken on over top of all that, but they are really well suited to to coordinate an effort like this. They know how to inspect these things. They have a cleanroom. They're, they're able to process this this large quantity in addition to the other things that they're doing.

Something else interesting that he said is, you know, we've talked a lot about workforce measures and social distancing. And that that is something that they've put in practice, they're running shifts with fewer people. But they've actually brought on some some temporary help. He said they put out a call and they got like a lot of college students and other people who are looking for work to help do the the packaging and just process this huge quantity of swabs that they're now handling.

Peter Zelinski

So we talked about 3D printing kind of being the first responder among manufacturing processes, but then passing the work off to established conventional manufacturing processes at higher volume, but not in this case. It sounds to me like test swabs are a product design well suited to additive manufacturing. And it now on these platforms that are designed for production additive, it's going to be like millions, scale quantity production through 3D printing.

Stephanie Hendrixson

Yeah, and the part is simple enough that you can make a lot of them. I think the number from Origin is that they can put like 1,500 in one build, and even like a Formlabs printer, which is a much smaller machine, you can put 300 in one build. So yeah, this is a an example of a part that might be actually really well suited to additive manufacturing.

Peter Zelinski

All right, I think that does it for this week. Follow us on social media. You can find both Stephanie and me. We're active on Twitter and LinkedIn and additive manufacturing. The brand we write for is on Twitter, LinkedIn, Facebook, Instagram. Additive Manufacturing dot Media is where to go to see our latest COVID-19 coverage as it relates to 3D printing but also coverage of additive manufacturing successes and technology in general.

Stephanie Hendrixson

And we'll put some links to related stories and other resources in the show notes below. Thank you for watching. See you next time.

Related Content

Zeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreDurable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreRead Next

Injection Mold or 3D Print? How Resolution Medical Pivots Production

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read More3D Printing and Coronavirus: U.S. Additive Manufacturers Share Their Experiences

The COVID-19 outbreak has brought both setbacks and opportunities for American manufacturing. 3D printing companies share their stories.

Read MoreNeed Parts? These Additive Manufacturers Are Ready to Help

Disrupted supply chains are just one more effect of the coronavirus pandemic. These 3D printing service providers are ready to help fill production gaps with parts, tooling and prototypes.

Read More

.jpg;width=70;height=70;mode=crop)