“The cost per 3D-printed part is almost always going to be more expensive than molding for us,” says Shawn Patterson. “But it comes without the cost of tooling—including its long lead times, maintenance and costly mold changes. When the material for the project is a match, that’s a win for 3D printing.”

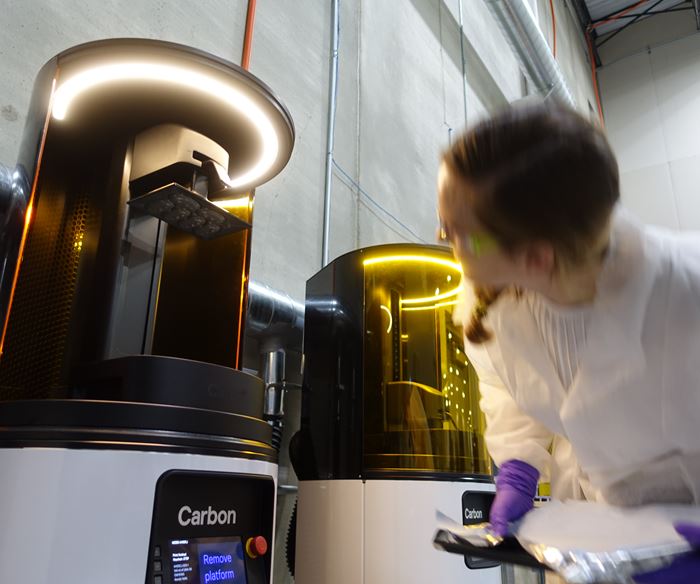

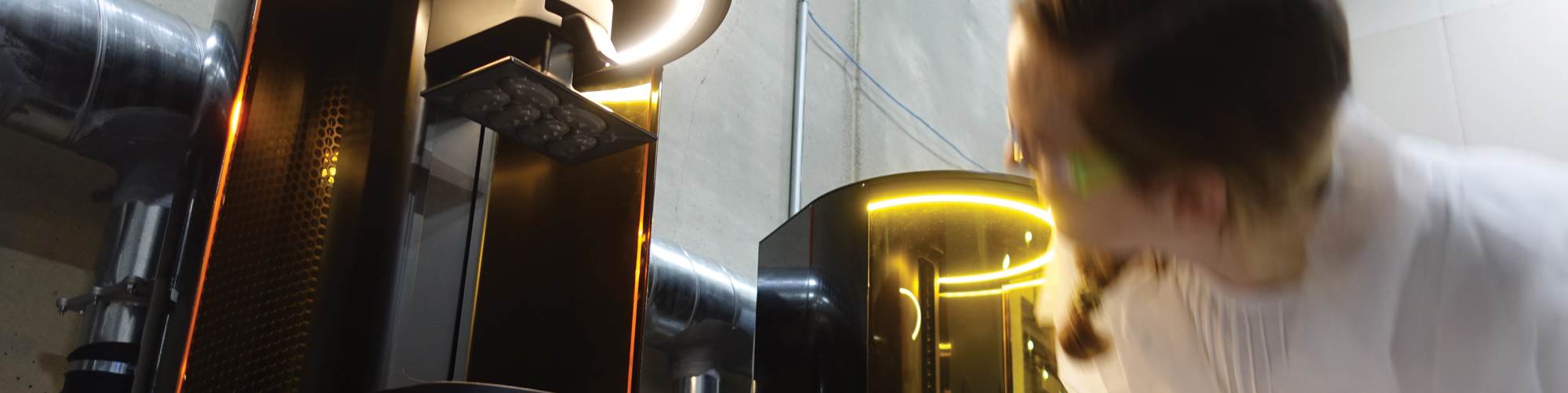

Patterson is founder and president of Resolution Medical, a Minnesota manufacturer that is seeing those wins for 3D printing play out right now. The company recently invested in Carbon Digital Light Synthesis (DLS) technology enabled by Continuous Liquid Interface Production (CLIP). As a Carbon Production Partner, company has committed to the installation of three printers at its Minneapolis facility. Its second printer had only just arrived when I visited in December 2018, but the company was already using these machines for production work that otherwise would have gone straight to its injection molding presses. Those presses won’t be leaving the shop floor any time soon, but the company can now provide 3D printing as another production option for its customers.

What will production additive manufacturing (AM) mean for Resolution Medical? Offering 3D printing to customers at the outset means faster time to market for new products and easier changes to existing ones. It means economic viability for smaller batch sizes and improved product design and functionality. Additive manufacturing via CLIP also promises the process control necessary for the medical device work that forms the core of the company’s business.

Bringing 3D Printing to the Foreground

Cofounders Patterson and Steven Schmidt started Resolution Medical in 2012, after working for about a decade at another medical device contractor. As their previous company began to grow rapidly, going after larger and larger jobs, some of its small- and medium-sized customers began to get overlooked. Patterson and Schmidt started Resolution Medical to serve those medical device firms that were being left behind, leveraging their own resources to get the business off the ground in a 10,000-square-foot facility. Its core business is manufacturing medical devices such as leads and implantable pulse generators, and complex delivery systems such as catheters, covering a range of operations. For catheters, for example, Resolution can manufacture the housings and components of the handle, create the composite catheter shaft, and assemble the final device including internal components in a cleanroom.

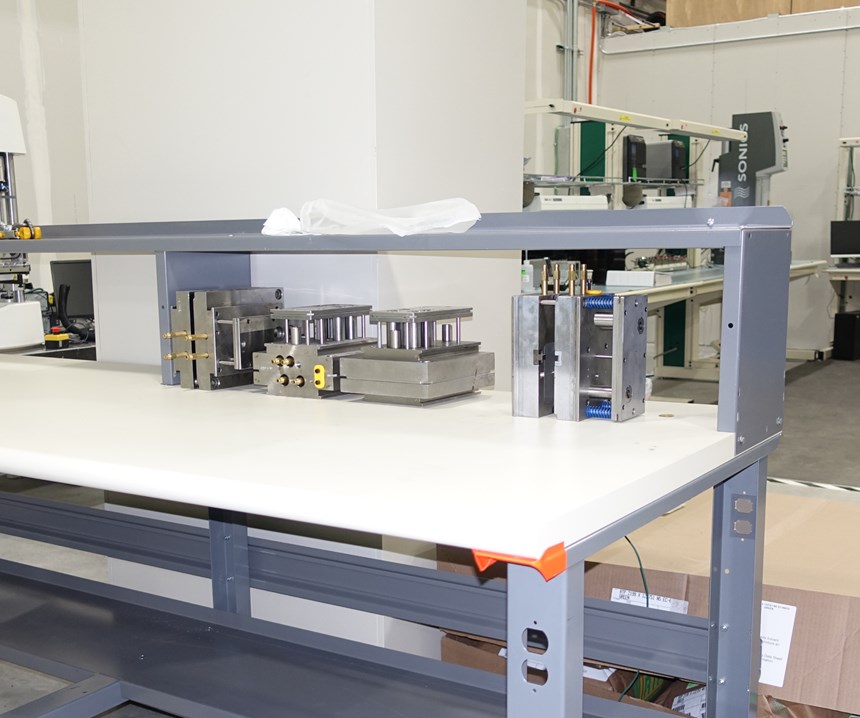

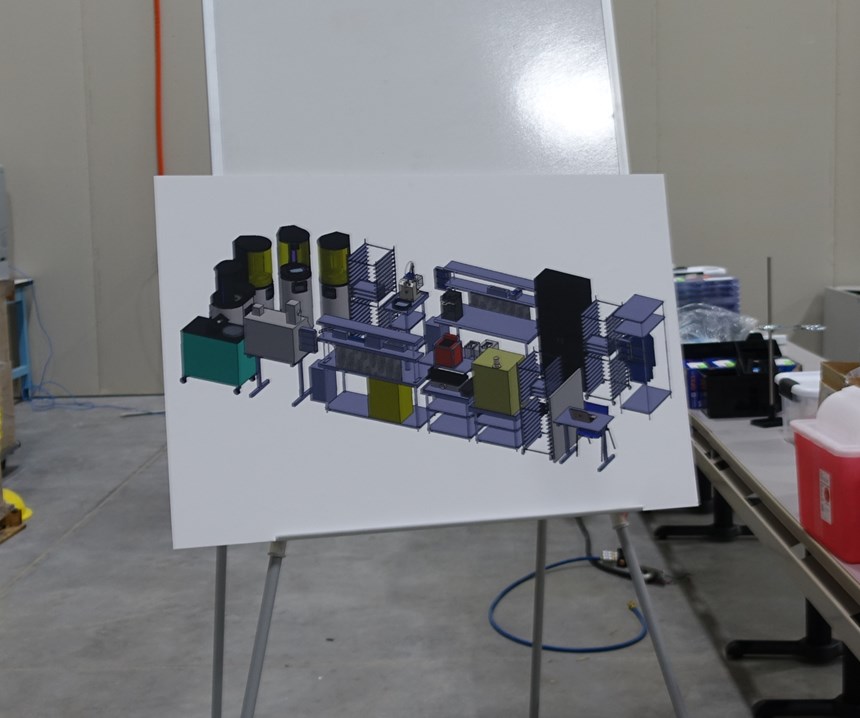

Today the company has about 50 employees, and in spring 2018 moved to a new, 36,000-square-foot space with room for two cleanrooms, a machine shop, injection molding presses, electromechanical assembly areas, controlled materials storage, decontamination labs, and research and development labs. This facility also has something new: a dedicated 3D printing department equipped to expand considerably, offering space and utilities to support as many as 18 Carbon printers in a footprint smaller than its injection molding department.

3D printing has always been present at least in the background at Resolution Medical. When the company was founded in 2012 its equipment list included an FDM 3D printer that is still part of its prototyping capacity. Its machine shop leverages desktop FDM and SLA printers to make tooling and fixtures. But its DLS 3D printers are different beasts. These machines are designed for speed, support biocompatible materials and are intended for production—as Patterson puts it, they have more in common with the injection molding presses than the desktop printers, though the promise they offer is entirely new.

Similarities and Differences with Injection Molding

Let’s start with the similarities. On a macro level, Patterson sees Resolution Medical’s 3D printing workflow as not so different from that for injection molding. “You have a tech or engineer tending to the machine, you’ve got resin, you’ve got maintenance on the equipment, you’ve got operators taking off parts and doing inspection,” he says. “It ends up looking a lot like injection molding, just maybe in more of a chemical lab setup.”

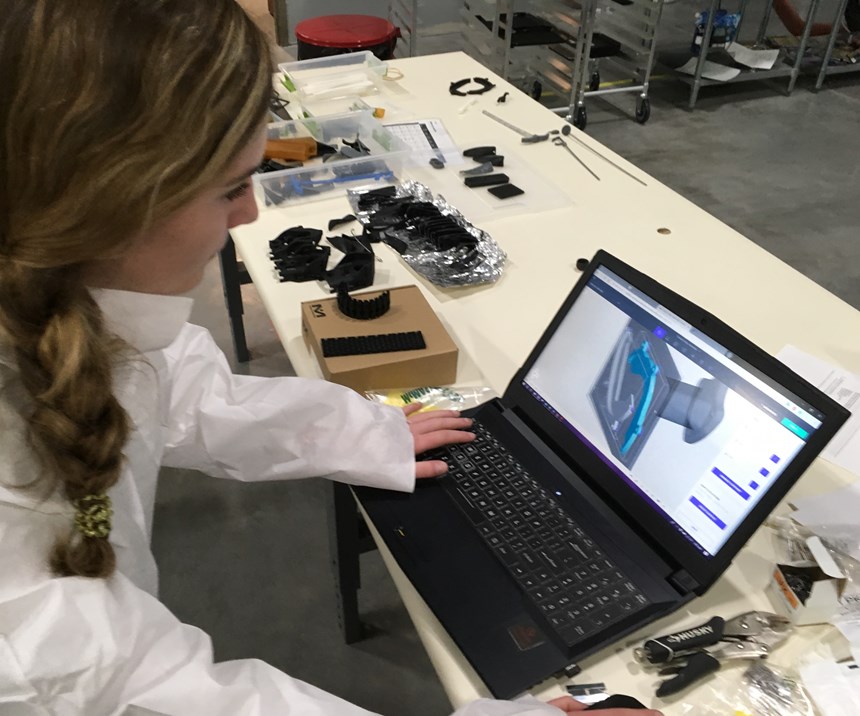

There are also overlaps in design that the company’s engineering team is discovering. According to Kenzie Veith and Taylor Wisgerhoff, product design engineers, there are some lessons from injection molding that translate into 3D printing with DLS. For instance, the principles of gate placements for injection molding can apply to the design of support structures for 3D printing; like gates, supports should avoid critical areas of the part and be located in places where they are easy to remove. With injection molding, designers worry about draft angle so that parts can be removed from the mold. With Carbon, draft is replaced by print angles and drainage: Can the uncured resin adequately drain from the part? Will it drain fast enough to avoid creating suction inside during a print?

But design is also the point where 3D printing begins to differ, and where its promise versus injection molding starts to show. Whereas injection molding is a method for production, DLS can be a strategy for production-plus.

“...that’s the kind of end thing the customer sees. They don’t want it to look like a 3D-printed part.”

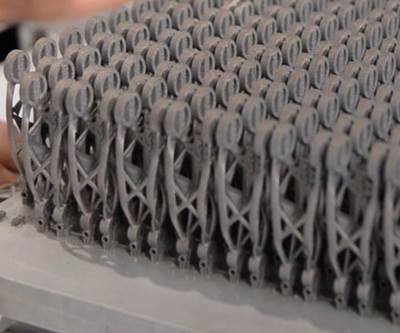

Assembly consolidation and simplification are clear wins for parts designed or redesigned for Carbon DLS. Other product improvements can come from features within the design software. Carbon’s latticing tool, for instance, will automatically adjust the parameters of the mesh as it approaches edges of the part to achieve the desired part properties and weight while preserving its outer design. Textures can also be applied to the part surface that wrap around edges, preserving their geometry; applying texture can be a way to hide the “grain” of the layer lines and give the finished part a more polished look.

“To apply texture to an injection molded part, you would have to build it into the mold design by drilling in texturing marks or sand blasting, and you certainly can’t do the variety of textures that you can do with Carbon,” Patterson says. “And that’s the kind of end thing the customer sees. They don’t want it to look like a 3D-printed part.”

On a workflow level, the Carbon printers offer ways of manipulating timelines by adjusting variables that wouldn’t be possible with injection molding. Part orientation is one of these. A long, thin part could be built horizontally, but, “Do you want to clean five parts every 30 minutes, or build more parts vertically and clean less often?” Veith asks.

Batch size and makeup are added variables. “You could think about one print equaling one catheter handle, for example, and print all the parts for that assembly in one build, for instance,” Patterson says. This might make sense in a development scenario where only one or several sets are needed, but for production purposes it would be more efficient to print one part number at a time.

The differences between injection molding and 3D printing processes don’t necessarily indicate whether a part fits one process over the other at Resolution Medical. Both are valid production options. Indeed, frequently it is the circumstance of the part, not its quantity or geometry, that determines which process is better suited.

Beyond the Mold

Why move an existing product from injection molding to 3D printing? The most common instance is that there is a problem with the part or the customer needs to make a change that would mean costly alterations to the tooling or new molds altogether. “The choice is either invest $100,000 in mold tooling and then maintain the tooling over time, or go with Carbon with no tooling costs and maybe invest a little bit more upfront work to get the part nailed down,” Patterson says.

One example where 3D printing played out as a production option for a new product involved a threaded nut. This is a part that would typically be machined or molded, and nothing about it suggests an obvious 3D printing candidate. However, the piece is small enough that Resolution Medical can 3D print a batch of 50 nuts in just half an hour—a speed that makes it competitive with injection molding, without tooling costs. The best-case scenarios for 3D printing at Resolution Medical are those where the application allows for the necessary upfront development time, the cost of tooling would outweigh the overall costs of setup and price per part, and the material needs are met by one of the Carbon resins. Most of Resolution Medical’s parts are printed with MPU 100, CE221 or SIL30, some of Carbon’s resins that are biocompatible and sterilizable.

“Once we get...into large-scale production, you can continue to pull files and rerun parts exactly the same way; across all those steps, everything’s safe.”

What about moving a 3D-printed part to injection molding? Once a part starts down the 3D printing road, Schmidt explains, it’s easiest to keep that part in an additive manufacturing production flow. “Once you set up or convert a part to 3D printing, you have a master file for the material. You still have to submit reports to confirm biocompatibility, but all the data is readily available,” he says. “If you go the other way, from 3D printing into molding, nine times out of ten you’re going to have to go back and redo all of that data to submit for biocompatibility.”

This issue of biocompatibility points to how 3D printing can be a consistency win for the medical industry. Part solid files, print layout, inspection drawings and additional information is highly controlled through Resolution’s quality management system and design controls just like other components. Because of the lack of tooling, the end part’s geometry and properties are determined by material and print file; the same file printed with the same material will result in the same part each time. Other controls like automated washing and validated oven curing settings provide added insurance to the process.

“Once we get that engineering side, and we get into large-scale production, you can continue to pull files and rerun parts exactly the same way; across all those steps, everything’s safe,” says Dale Carlson, senior product design engineer.

Seeking the Material Win

Resolution Medical now has its three Carbon M2 printers running two shifts during the week, as well as some weekends. The 3D printing area of the shop is set up, however, to support up to 15 more printers as a dedicated additive manufacturing cell.

Resolution Medical also sees growing opportunities as materials continue to advance. Currently, resin and equipment costs, along with some design constraints, are the primary limiting factors for DLS, but costs are coming down, Patterson says. That’s partly a result of Carbon’s bulk resin pricing introduced in 2017, and as well continued increase in resin volumes. Already it’s rare that Resolution can’t come up with an acceptable material for its customers, so more affordable resins will help to expand the economic cases where 3D printing makes sense. The company expects that more production will move this way in the future, with products developed, launched and then produced on the same 3D printing platform.

“The speed at which you can iterate is a game-changer,” Schmidt says. “If you can get the customers locked in at that early stage, they can get through clinical and into the market even at lower and mid volumes. This is prototyping and manufacturing.”

Related Content

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreDurable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read MoreCranial Implant 3D Printed From Hydroxyapatite Ceramic: The Cool Parts Show #76

Cranial implants are typically made from titanium or PEEK; in this episode of The Cool Parts Show, we look at how implants made from a bioceramic can improve osseointegration and healing.

Read MoreRead Next

The Technology House Steps into 3D Printing for Production

The Technology House was founded on stereolithography for prototyping, but each step forward has been a move toward production. The company is now 3D printing end-use parts, enabled by Carbon’s SpeedCell line and durable materials.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreAdditive Manufacturing Is Succeeding in Production! Here Are Examples

We are no longer predicting that additive manufacturing will be used in production — because it already is. Find real stories of 3D printing for full production at AM's leading edge in this collection.

Read More

.jpg;width=70;height=70;mode=crop)