Additive manufacturing can create parts. Can it also create jobs?

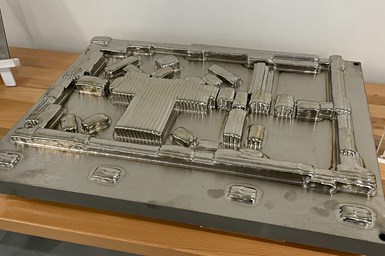

Norsk Titanium’s Rapid Plasma Deposition is a wire-fed DED process. Parts like this offer properties comparable to forging and can proceed to machining without heat treating, the company says. The part seen here is for General Atomics Aeronautical Systems, which is developing components with Norsk for use in unmanned aerial systems.

Yes. And demonstrating that it can is just one of the missions of a newly opened AM factory in the northern part of New York state.

Start with the opening statement above: Additive makes parts. Specifically, it can make high-quality parts in a challenging metal more economically than other processes. Norsk Titanium, founded in Norway, is the inventor of an AM process it calls Rapid Plasma Deposition (RPD), a wire-fed method of directed energy deposition (DED) able to produce titanium 6Al4V parts featuring forging-like properties and no requirement for hot isostatic pressing. When Norsk began to commercialize RPD in 2016, it faced the question of whether to make machines for others or make machines for its own use as a contract manufacturer. Choosing the latter course meant Norsk would be able to measure parameters and outcomes for every component produced through this process and use the data to make the process better over time. This is the route the company took; Norsk became an RPD contract producer. And aerospace, particularly the commercial aircraft sector, is the market it saw as most promising.

The company’s facility in northern New York has future capacity already waiting on the production floor. Some machines await final assembly but are otherwise ready to be brought into service.

Now here is how that development connects to jobs, specifically job creation in the United States: Norsk’s first major production opportunity came from Boeing. The U.S. aircraft maker identified a series of titanium components for its 787 airliner that could be produced more efficiently and with less wasted material through RPD. Taking on this production meant Norsk needed a production facility, and it aimed to build one in the United States to be near its leading customer. New York state extended the winning offer: The state would build an 80,000-square-foot facility for Norsk in Plattsburgh, New York, and would fund the production and installation of the RPD machines Norsk would use to equip this site.

The primary requirement: Norsk would need to grow to employing more than 230 full-time employees at the site within the first 10 years of operation.

Stephen Eaton is VP of operations for the Plattsburgh factory, which opened and officially began operations in 2019. A global pandemic and the resulting hit to Boeing’s demand adversely affected the site’s activity during its first two years. But even so, Eaton says, “I believe we will hit the employment goal not in year 10, but in year six.”

Director of production engineering Steve Schuster (left) and VP of operations Stephen Eaton help to lead a U.S.-based production team for the Norwegian company.

I recently visited the Plattsburgh site, where I spoke with both Eaton and director of production engineering Steve Schuster about the advance and promise of AM part production here. Today, this factory, plus a smaller companion site nearby that opened while the factory was under construction, employs 53. Next year the number will likely be 80. The new facility has nine RPD machines in operation, and 11 more already on the floor and soon to be brought online. AM is largely an unattended production process and RPD is no exception, but Norsk’s business is growing so rapidly that even the staffing needs of an unattended process are expanding quickly. This factory is in production now with about 50 different part numbers seeing annual volumes of at least 100 units apiece, and before the end of 2024, that range of ongoing production part numbers will have expanded to 125.

This structural component for the Boeing 787 is seen here in both the form made via RPD and in its final form after finish machining. The final part is 0.45 kg.

Aircraft will remain the driver of this growth. Other aircraft makers also see cost-saving opportunity in parts made with RPD, and new orders from these sources are ramping into production.

However, another meaningful factor will be Norsk’s first significant production opportunity outside of the aerospace industry. It turns out that DED of titanium has an important role to play in semiconductor manufacturing. And in this application, says Schuster, RPD displaces an operation that is secondary to the one it is most commonly measured against.

“We usually compete against forging,” he says. “Here, we were competing against machining.”

Escalating production demands plus the company’s commitment to hiring for its New York facility mean training of new employees is a regular and ongoing part of the plant's operations.

Titanium Parts at Lower Cost

That measure — production methods and their costs — goes all the way back to Norsk Titanium’s founding and its reason for existing. Company founders and RPD inventors Alf Bjørseth and Petter Gjørvad were driven by the high cost of working with titanium, and aimed to develop a process that could deliver otherwise costly titanium components at a lower unit cost. Wire-fed DED offers a way to build titanium parts both without the tooling investment needed for forging, and without the effort, energy and material waste that goes with hog-out machining. Norsk’s process goes farther than DED in general (more on that in a moment), but its customers today come to the company to realize these very benefits: avoiding the need for forging in producing titanium parts and/or achieving nearer-to-net-shape titanium parts that deliver a better ratio of material purchased to material actually used in the finished plane. That is, better “buy to fly” ratio.

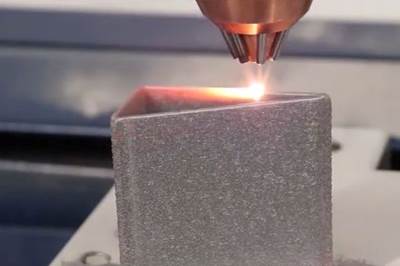

Norsk is the sole user of its own machines, developed within the company. The proprietary additive process on these machines involves separate torches for preheating and melting plus forced argon gas for cooling.

Norsk realizes forging-like properties through its DED process, an important distinction. Specifically how RPD does this is proprietary, but the elements of the process include two plasma torches applied to the metal in quick succession — one to preheat the surface and one to melt the wire stock — followed by forced argon gas applied to each layer in an immediate cooling step. Important process parameters and how they vary throughout the build are among the details the company guards. Schuster says parts resulting from the process behave so much like forgings that they are machined just like the parts they replace. “Our customers don’t have to relearn their machining,” he says. The RPD part offers a smaller envelope of stock to remove than a comparable forging, but after accounting for that difference, he says, “You use the same tools and tool paths you would on a forging.”

Trays for silicon wafers now begin as preforms like this one. Machining needed to complete the part is considerably less than hogging out the entire form, allowing the semiconductor equipment maker to keep up with escalating demand.

The new semiconductor work does not involve forging, but it does even more to reduce machining. Semiconductor equipment maker Hittech produces titanium trays carrying silicon wafers. Each of the carrier trays used to be hogged out of a block of solid titanium, but now Norsk provides this company with 3D printed preforms that are much nearer to net shape. The solid blocks were 220 kg; the RPD replacements are 80 kg. The difference is 140 kg of titanium that now does not have to be machined. That represents dramatic savings in material, but Eaton says the equally important factor was time savings.

The RPD process involves a build plate, but the plate is generally incorporated into the part design. RPD features plus the build plate are finish machined together to realize the final form.

“They turned to us to help them keep up,” he says. Semiconductor demand has increased. Milling 140 kg of titanium produces a long machining cycle time. Hittech had to either add more machining centers or find a different way, and it did the latter. The result is a success that departs from common expectations about metal additive production. Metal AM is generally seen as producing parts designed for additive that are made at relatively slow production rates. But here, AM took on a production part as-designed, and will help realize the needed production more cost- and capital-efficiently than machining alone would have allowed. Norsk will be shipping these preforms to Hittech for finish machining at expected annual rates of about 100 units apiece for four different tray models.

Optimization Through Control Over Production

Serving as the sole user of its own RPD process allows Norsk to control production inputs. One of these is the wire. The Plattsburgh facility is served by a single titanium wire supplier.

Serving as a part maker, rather than machine supplier, is the way Norsk saw for realizing the full promise of its proprietary technology. Making machines only for its own use and acting as a contract manufacturer allows the company the best chance to control production outcomes by controlling all the production inputs. Material is a vital example of this. The Plattsburgh factory works with just one carefully chosen supplier of wire feedstock it uses in its machines. (Norsk’s focus is even more specific than its name implies. R&D work with other materials is underway, but for now, a more fitting and literal name for the company might be “Norsk Titanium 6-4.”) Making machines only for its own use and acting as a contract manufacturer also allows the company to gather data on every part made, which helps it both further refine the process and offer validation for future production opportunities.

Plus, the build speed is so fast that a small number of machines accounts for considerable production. Eaton says, “If we could have run machines nonstop around the clock, then five machines could have handled all our production this year, and 12 machines would be able to handle it next year.”

Machines cannot be run nonstop, because there are delays for job changeover along with maintenance needs — but even so, the point can’t be understated: AM part production for a process optimized to a particular material is so productive that just one site can account for considerable output. Norsk’s 80,000-square-foot facility (60,000 of which is production) currently offers, in theory, 700 metric tons of annual capacity. The machines that will offer future capacity expansion have already been built, for the most part, and are already waiting on the Plattsburgh production floor in some state of disassembly. This facility can scale up quite a long way — many multiples of its current production — before another facility like it would be needed. Indeed, the immediate needs related to future production are part of why Eaton can forecast the site’s job creation with such confidence. Part of the labor demand Norsk is facing is for technicians to help bring its equipment, the machines that are ready and waiting on the plant floor, fully into service and into production.

Aircraft of various forms account for the majority of the plant's work. The company's Defense Articles Development team is concerned with ITAR-related developments, including the unattended aerial vehicle component. Seen here, from left to right, are team members Chris Hickey, Elijah Gorton, Joe Girard, Steve Schuster, Tristan Gilmour, Greg Reynolds and Patrick Borrette.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

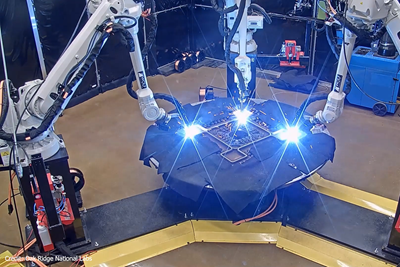

Robots Combine for Faster DED Build Rate (Video)

The Medusa system merges multiple robots into a single system for efficient additive manufacturing of large metal parts.

Read MoreInfrared Camera Supports Real-Time Process Control for Laser Metal Deposition and Cladding

New Infrared Technologies’ Clamir system provides continuous meltpool monitoring for cladding and directed energy deposition 3D printing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More