Video: Update on Hybrid Manufacturing

Greg Hyatt of DMG MORI notes expanded range of subtractive operations and applications likely to benefit from hybrid.

DMG MORI continues to explore and advance the “hybrid” concept combining additive and subtractive operations into one machine, says Greg Hyatt, vice president and chief technical officer for the company. He describes the company’s progress in this video. Grinding and ultrasonic machining are additional subtractive operations that can complement additive, he says, and in the future, industries not typically associated with additive manufacturing are likely to show interest in this means of making parts.

Transcript:

Pete: I’m Pete Zelinski with Additive Manufacturing magazine. I’m here with Greg Hyatt, senior vice president and chief technical officer with DMG Mori. Dr. Hyatt, you have been involved for a number of years now in hybrid manufacturing. Hybrid systems combining additive manufacturing with CNC machining in a single platform. Make the case for the hybrid concept, why is that idea valuable for deploying additive manufacturing?

Greg: I think it’s absolutely essential, as we move from applying additive largely to rapid prototyping to actual production of parts because what’s most exciting about additive is the new designs that are enabled, that it enables design engineers to take what were previously assemblies, build those as a single piece, eliminating the joints and flanges, the leakage, the assembly time, but that means the machined features get trapped inside. So, it’s impossible to machine those features after the fact. The only way to give the design engineers that degree of freedom is to be able to machine them in process.

Pete: Yeah, DMG Mori was among the first leaving machine tool builders to introduce a hybrid machine. It’s been out there for a little while now. What have you learned, are there ways you’ve gotten a better sense of the possibilities for this machine and what can it do?

Greg: Yes, we’ve expanded. I guess our definition from hybrid from including only milling and turning to grinding and ultrasonic machining, which extends the range of applications extends the range of work that can be consolidated into a single operation, and that has been exciting.

Pete: I wonder if you could talk about a recent test or experiment with the hybrid machine? Is there any new application that you’re playing with or learning about right now?

Greg: No, there are dozens, so, but I think you’re gonna force me to talk about one, so I think I would choose titanium and the reactive metal. The traditional solutions that have addressed the unique challenges of reactive metals and additive machinery don’t apply to the hybrid so we had to invent our own enabling technology. We’ve done and we’ve commercialized titanium and in the future, we’ll be extending the reactive portfolio into other alloys.

Pete: Additive and machining our complementary processes recognizing that, what is the future that you see? Are there particular sectors, industries, types of products that are particularly prone to be affected going forward by additive and machining working in tandem?

Greg: Yes, I think in particular we’ll see a lot of interest in the coming year or two. In heavier components from energy in general, oil and gas, mining, also agriculture, industrial equipment, the fields where the components are large and they didn’t fit in the original generation of additive equipment. So, there’s a large pent-up demand to be able to build these longer, more robust components that is finally being enabled.

Related Content

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreNew Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

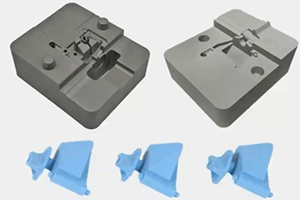

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More