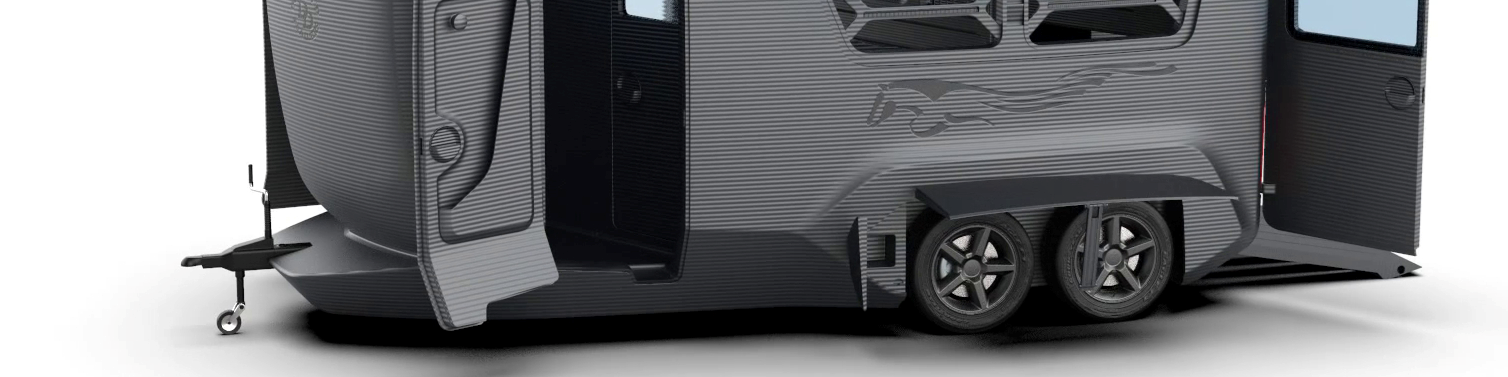

A rendering of a 3D printed horse trailer. Double D Trailers sees large-format additive manufacturing (LFAM) as an opportunity to not only deliver custom trailers more easily, but to also reduce weight and improve their efficiency in various ways. Image Credit: Double D Trailers

“It would be easier to build the same widgets over and over,” says Brad Heath, founder of Double D Trailers. “It’s much harder to build custom.”

But Heath’s company specializes in this challenge, designing and sourcing horse trailers made to customer specifications. Soon, some of these trailers will be made via large-format additive manufacturing (LFAM). Robot-based 3D printing will bring reduced labor and weight to these recreational vehicles, plus advanced new features and a more flexible way of producing exactly the trailer a client wants. And, Heath says, the company will gain more control over its own components and supply chain.

Meeting Manufacturing Challenges for Custom Trailers

Double D’s patented innovations include the SafeTack compartment seen at the left, which keeps the riders’ tack (saddles, bridles, etc.) separated from the horses being transported. Photo Credit: Double D Trailers

Heath founded Double D Trailers in 1994 with two other family members, originally distributing then manufacturing horse trailers, farm equipment and similar items at a facility in Pinkhill, North Carolina. But with the recession in 2008, “The world stopped turning for recreational vehicles,” he recalls. Both Double D and one of its key manufacturing partners were suffering from the reduced demand, and in 2011 the North Carolina company decided to shut down its production and transfer the remaining work to a Wisconsin-based supplier. Since then, the company has worked closely with this supplier as its focus has shifted to the design of new models and custom client trailers, plus the development of patented innovations for these vehicles.

Coronavirus in 2020 brought another bump in the road, this time in terms of supply chain challenges. “Lead times have stretched to 10 months or a year for a new trailer,” Heath says. Shortages of materials and parts, coupled with a drop in quality for those parts and a lack of skilled labor, have combined to raise costs for these products as well.

“The average cost for one of our horse trailers has risen 62% since 2020,” he says. A standard trailer model that might previously have cost $30,000 is now priced above $50,000 as a result of increasing costs in manufacturing.

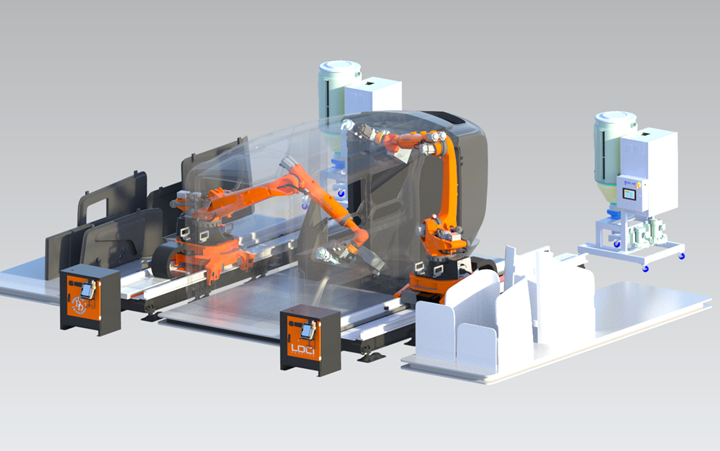

Loci Robotics’ current setup with just one robot does not have quite enough build space to print a full trailer right now (hence the scaled-down prototype). But two robots on tracks could print the entire structure working in tandem. Image Credit: Loci Robotics

But for the last year or so, Heath and his company have been actively pursuing a possible solution for some of these challenges. Double D Trailers has been exploring the viability of a 3D printed horse trailer with startup Loci Robotics out of Knoxville, Tennessee. The latter uses a 3D printing head mounted on a robot arm to build large-scale structures from polymer pellet material; the printhead can also be swapped out for a milling tool to perform finish machining in areas where it is needed. The companies recently completed a successful scale model of the horse trailer prototype.

Along with demonstrating the viability of the technology, the prototype unveiled a new streamlined and aerodynamic design for a horse trailer. The concept was developed with One One Lab, an automotive design studio based in Poland. Heath says he wanted something futuristic, a trailer that would draw inspiration from cutting-edge designs seen in next-generation automobiles.

Streamlined Design, Streamlined Manufacturing

The single-piece (monocoque) design for the trailer body brings manufacturing benefits as well. Today conventional trailers are built through a multi-step process that involves welding together a metal chassis and frame; installing the flooring, roof and skin of the trailer; mounting doors, ramps and dividers; installing windows; and painting. For a horse trailer that also includes living quarters for people, the process includes the installation of plumbing and electrical systems as well as the addition of trims and other touches that human occupants expect.

Fabricating a horse trailer conventionally requires quite a few individual parts and a fair amount of welding and other assembly steps. Photo Credit: Double D Trailers

3D printing can simplify and automate this process in either case. With robot-enabled large format additive manufacturing, it is possible to 3D print the entire body of a horse trailer in one go including the chassis, with much less assembly and without the need for substantial human involvement or intervention. Some components of the trailer will still be made separately and installed (like windows and fender covers), but the manufacturing process will be highly consolidated compared to present day.

A conventional two-horse bumper-pull trailer like this currently retails around $50,000. 3D printing the same configuration will likely come at a higher price tag, but with reduced weight, shorter lead times and greater opportunities to customize. Photo Credit: Double D Trailers

“I don’t want to buy steel, pay for a welder and a paint booth, and order trim and windows from a supplier,” says Heath. With 3D printing, he says, Double D could potentially print nearly all the parts it needs in-house with the exception of a few items including the wheels, axles and tires.

Integrated, “Smart” Climate Control

Heath also sees the potential to incorporate upgraded and entirely new features into horse trailers with AM. One that he is most excited about involves climate control. Today, most horse owners open windows in their trailers to provide air flow and ventilation while towing or parked. The 3D printed trailer design includes (printed) windows that can open, but that are designed to be kept closed during hauling for sound insulation, Heath says.

The windows on the 3D printed trailer can be opened, but are designed to stay closed during transport. Smart climate controls inside the trailer will monitor horse health and engage air conditioning (with built-in ducting) when needed. Image Credit: Double D Trailers

To ensure that horses stay comfortable, however, Double D Trailers is developing an Internet of Things (IoT) enabled climate-control system that will integrate with ducting 3D printed right into the structure of the trailer body. Thermal cameras will monitor horse body temperature and automatically activate fans and vents to control the climate inside the trailer. An associated app will enable horse owners to monitor both their animals and trailer conditions. The IoT solution is applicable to standard trailers as well and could be retrofitted onto existing vehicles, but 3D printing offers the unique opportunity to easily integrate features designed specifically for this purpose.

3D Printing Materials and Advantages

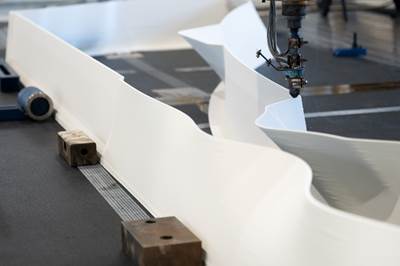

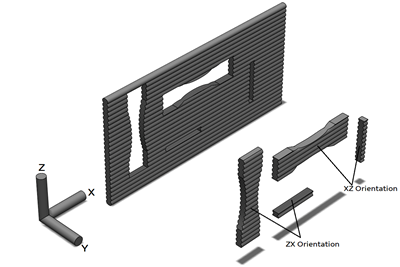

At this point, Double D Trailers is on the hunt for exactly the right platform and materials to make these trailers in production. The final monocoque bodies will likely be printed from a 10 to 20% carbon fiber-filled ABS, but dialing in the exact blend needed for safety, performance and aesthetics is still a work in progress.

Most of these materials are black due to the carbon fiber content, but a light grey or white would be more preferable for climate control and horse comfort — in addition to temperature control, horses prefer bright, well-lit environments to dark ones. Materials testing is ongoing; in addition to tensile and fatigue testing (even tests that simulated a kick from a horse hoof), the company is also working with partners to evaluate the composite polymer’s resistance to horse urine, UV exposure and more.

Tests so far have given Heath confidence in the durability of the 3D printing materials. Switching from steel to carbon fiber-reinforced polymer composite will also bring weight savings; the full-scale prototype will weigh about 3,500 pounds compared to 5,100 pounds for a conventional steel trailer in the same size and configuration. That reduced weight potentially translates to fuel savings for the towing vehicles.

And, while repairs to a monocoque 3D printed trailer would be challenging, Heath sees opportunities to grind up and reuse damaged products in the 3D printing process for potential sustainability benefits. If a printed trailer gets damaged enough to need repair (most likely in a traffic accident), Heath anticipates that simply reprinting the vehicle will be the safest and most expedient way to replace it and plans to offer longer warranties on these trailers as a result.

(The final cost of a 3D printed custom horse trailer is still yet to be determined, but for a two-horse trailer as seen in the prototype concept art, the price tag might be around $70,000. That’s a bit more than the $50,000 conventional version — but includes the new features described above and can accommodate more flexibility in customizations without necessarily adding additional cost.)

Forward With LFAM

Double D Trailers expects that a two-horse trailer like this could be 3D printed in about 15 hours, speeding lead times and helping the company deliver more value with manufacturing capacity it plans to own and operate internally. Image Credit: Double D Trailers

Taking the 3D printed horse trailer concept into production will involve the purchase of a 3D printing system to be operated by Double D Trailers in Wilmington, North Carolina. The company is currently under NDA with a supplier of a dual-robot LFAM platform that is large enough to manufacture the full-scale trailer bodies in one piece, exceeding the current capacity of the Loci Robotics system.

With both robots working in tandem, Heath estimates that the company could print one two-horse trailer in about 15 hours and envisions producing two or three per week in the beginning. As demand increases, the company can add additional printer cells to replicate its capacity. Down the road, Heath also intends to vertically integrate the 3D printing business to produce the feedstock in house as well, giving the company further control over its supply chain.

There’s still plenty of work to do to bring this product to the market, but Heath is optimistic. “If it’s possible, we’re going to do it,” he says. “We’ll be printing a full-sized prototype within the next six months, and we already have preorders for 2024.”

Related Content

Sustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreVideo: A Mechanical Method for Metal Powder Production

Metal Powder Works has developed a method for producing powders from solid barstock, no melting required. This video covers how the process works and benefits of mechanical production of powders.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreRead Next

3 Points About 3D Printing Large Parts We Can Learn From the Lunar Habitat (Video)

Ingersoll Machine Tools describes the capabilities and promise of large-scale additive manufacturing as seen in the 3D printed sections of the Rosenberg Space Habitat.

Read MoreAutonomous Underwater Vehicle With 3D Printed Hull: The Cool Parts Show #24

Our first episode of The Cool Parts Show from inside a 3D printer! Big Area Additive Manufacturing (BAAM) produces exterior components of a robot submarine and changes how this AUV is marketed.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read More

.jpg;width=70;height=70;mode=crop)