Can Chemistry Set AM Free of the Cost and Constraints of Support Structures?

Support structure removal is costly and can prevent supports from being used in some areas of the part. This researcher may have found the answer that will make support structures easy.

Dr. Owen Hildreth, a researcher at Arizona State University in fields including chemical kinetics and corrosion, was in the audience when Dr. Tim Simpson of Penn State University came to ASU to speak about additive manufacturing. Simpson is one of the leaders of Penn State’s additive manufacturing center, CIMP-3D. At the time, ASU was about to launch its own Additive Manufacturing Center. In his talk, Simpson showed images of the AM work at his facility, including a photo of one of the students laboring with hammer and chisel to remove support structures from a metal AM part. Noting the difficulty of support-structure removal, Simpson joked, “Does anyone here know of a water-soluble metal?”

Hildreth thought something like, “Do you want one? I can do that.” Most metals are technically water-soluble. Applying solubility to solve this problem seemed to him achievable. Maybe water alone would not provide the mechanism, but certainly he saw how to perform a metal additive build with support structures that would dissolve so that they wouldn’t have to be machined or mechanically removed.

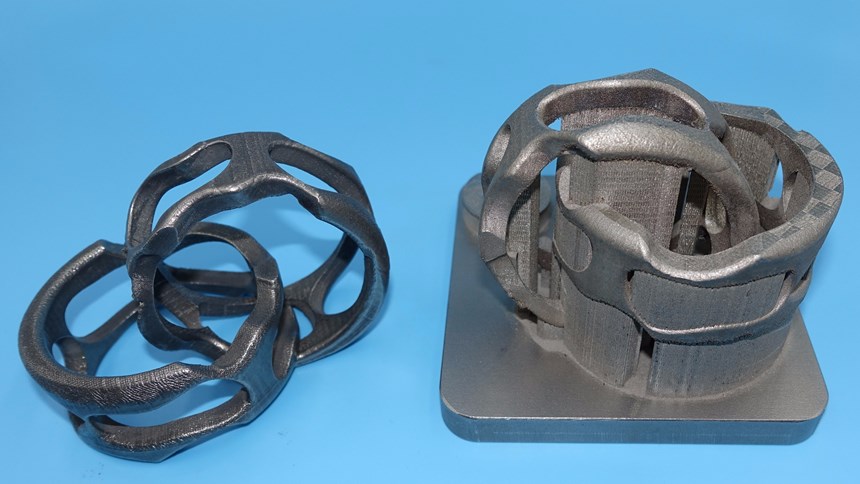

The most obvious solution he saw was to use two different metals. We have reported on his success at producing dissolvable supports in directed energy deposition AM. However, what about powder-bed machines? A powder-bed metal AM process allows for printing with only one metal, necessitating an altogether different approach to making support structures dissolvable.

As a follow-up to the multi-material work, Hildreth and his research team, working with Simpson and his team, recently found and validated that different approach. The solution they developed could, in principle, be applied in any setting using powder-bed AM. Indeed, the solution they found for realizing dissolvable support structures on a powder-bed machine could be applied using easily obtainable items available for a total cost of under $2,000.

The accomplishment potentially represents far more than just a novel alternative to mechanical removal of supports. That mechanical removal, whether through manual labor or machining, represents a significant share of the cost of a typical metal AM part. Indeed, the cost of machining away support structures might easily exceed the cost directly involved in 3D printing those parts. And then there are the constraints that mechanical support structures introduce. Today, elaborate internal features in metal 3D printing are not attainable if producing those features would necessitate support structures that no tool would be able to reach to cut them away. Dissolvable support structures would change this. The dissolvability would bring metal 3D printing nearer to the ideal of printing any geometry the user wants.

Meanwhile, Hildreth’s process for powder-bed parts also has this interesting side effect: While removing support structures, it also happens to improve the surface finish of the parts themselves.

All it took, he says, was finding a chemical mechanism that would stop at the right time, dissolving only the supports but not the part itself, even though they are made from the same metal. To find this mechanism, he looked to metal corrosion, and he looked to welds that have gone wrong.

Use the Horribleness

Why does a metal dissolve through corrosion? And when a weld fails so that the two joined surfaces end up separating, why does this failure occur? In both cases, one reason Hildreth points to is the presence of excessive carbon, which is reactive. “High carbon content can be horrible for the integrity of metal surfaces and metal welds,” he says. But here is a case where that fact is useful.

Hildreth’s process dissolves carbon into the metal surface of a 3D-printed part and its support structures, doing so to a depth that is roughly the same as the support structure’s thickness. This makes the carbon-infused metal—and only the carbon-infused portion of the metal—sensitive to dissolution using a solution of potassium chloride and nitric acid.

“Basically, we use the horribleness of carbon,” he says. “We take the horribleness and put it to work for us.”

To find the cost-effective way to get carbon into the metal part’s surface, he looked to blacksmithing techniques of years past. In the process known as case hardening, a part can be carburized by exposing it to a compound while hot, then quenching it in water. One active ingredient in the case hardening compound is sodium hexacyanoferrate. The carburization works because this compound infiltrates carbon into the surface, he says. And he took note of this water quenching as an important clue. This step shows that sodium hexacyanoferrate is water-soluble. Thus, Hildreth found the elements of the process he would go on to develop.

His process uses the water solubility in this way: A supersaturation of sodium hexacyanoferrate in water is used to apply the substance evenly all over the part. After 3D printing, the build is dipped in this solution. Then, the heat necessary to infiltrate the carbon out of this agent comes from annealing, which is a step the metal 3D-printed part almost certainly would have had to undergo anyway. The result, after this annealing step, is a metal part that has been “sensitized” to dissolution. A subsequent step is then to soak it for a time in the potassium chloride/nitric acid solution that does this dissolving.

Importantly, though, the metal build is sensitized to dissolution only to a certain depth. Beyond that depth, the metal will not further dissolve no matter how long it keeps on sitting in the acid.

That depth is about 100 microns. The carbon infiltration goes that deep into the surface of the metal, all around the part. That means the part itself loses an outer envelope of 100 microns, a stock envelope that could be added to part in CAD, though this is the same amount of material that might otherwise be lost in a follow-up benching step to improve surface finish. Meanwhile, as long as the support structures were all designed to be just 100 microns thick, all of those support structures will go away.

And that follow-up benching step might go away as well. Surface finish improvement was not the objective sought in this process, but it is a useful side effect. On stainless steel parts, Hildreth's team has observed surface finish changes from 350 microinches Ra in the as-printed state to 160 microinches Ra after the support structures have been dissolved. Another useful side effect: The mechanism of dissolving away supports also serves to quite easily dissolve away any clumped or trapped powder still remaining from the additive build.

Bring the Buckets

Is this method practical? Abundantly so, Hildreth notes. Technology required consists of a power supply ($300), a reference electrode ($200) and buckets compatible with nitric acid ($100). Moreover, this method is scalable for production. In fact, it is far more easily scalable than machine tools or hammers and chisels. All that is required to accommodate a bigger batch of parts is a greater volume of the necessary chemicals and larger containers for soaking.

Is it ready to use? Basically yes, he says. It has been proven for stainless steel and Inconel 718. He believes he knows the chemistry that will work for titanium and aluminum. He just hasn't gone that far yet because he has reached the end of the pool of funding that has so far fed this research. And testing to validate mechanical properties of the part’s surface after this treatment has not yet been completed. Even so, the process is available to use by anyone wishing to license it from ASU.

Not only is the process easy to use, Hildreth says, but it also makes support structures easy to use. Any structure able to be reached by a fluid can now be removed; designers can now put support structures practically anywhere they wish. The only requirement is keeping to a maximum thickness of 100 microns. To make this requirement easy to meet, he is working with a manufacturer to develop the design rules and optimal forms of support structure systems in metal AM built solely out of 100-micron-thick members. Ideally, the result of this investigation will ultimately be a “dissolvable supports” checkbox in AM software that automatically applies this style of support system throughout the design of the build.

Related Content

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read MoreFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More