Articles

AM So Far: A Conversation on 10 Years of Covering Additive Manufacturing: AM Radio #11A

Additive Manufacturing Media marks its 10-year anniversary. AM Radio hosts Stephanie Hendrixson and Peter Zelinski look back, talking about the advance of industrial 3D printing and expansion of the ways we report on it.

Listen3D Printing Reduces Time, Cost of Building Molds for Composites

Massivit 3D’s cast-in-motion technology uses a 3D printed gel to expedite production and lower costs associated with making molds for large, fiber-reinforced composite parts.

WatchOur 10 Year Anniversary! We Note Changes, Revisit Leading Stories

This month marks the 10-year anniversary of Additive Manufacturing Media. We return to find new stories at companies we have covered in the past, and we take stock of how dramatically AM has advanced in the span of just one decade.

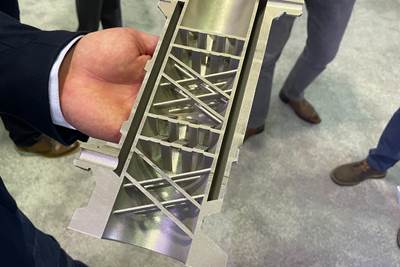

Read More3D Printed Composite Bracket Versus Machined Steel: The Cool Parts Show #41

Can a 3D printed composite bracket work as well as one machined from steel? Can it also be faster to make and cheaper to produce? In this episode of The Cool Parts Show we explore a new way of manufacturing a bracket for a helicopter door hinge, and similar small parts today made from metal.

WatchCan Additive Manufacturing Materials Challenges Be Solved with Design?

TPU manufacturer Lubrizol says yes: Production-ready materials are here, and 3D printing-enabled design has only begun to realize their capabilities.

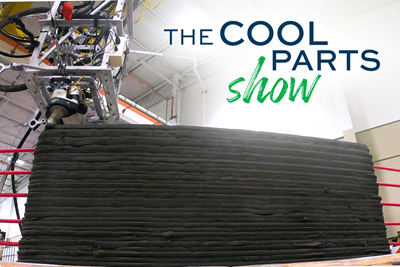

Read MoreThe Broad Promise of Large-Format AM: AM Radio #10B

3D printing makes very large parts easier to produce. Julia Hider and Peter Zelinski discuss the promise of additive manufacturing for big parts on the AM Radio podcast.

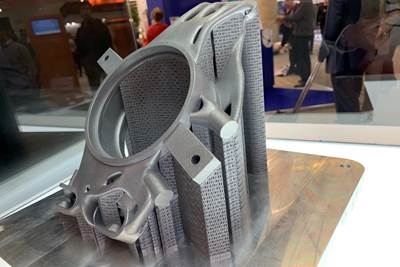

ListenVideo: Functional Excavator Features 3D Printed Parts

Oak Ridge National Lab's Project AME swapped an excavator's cab, stick and heat exchanger for 3D printed parts. Stephanie Hendrixson and Peter Zelinski get the scoop.

WatchZooming in on Micro 3D Printing: AM Radio #10A

This week on AM Radio, Peter Zelinski and Julia Hider discuss additive at the extremes, including micro 3D printing. What are the opportunities and challenges of 3D printing on a microscale?

ListenMold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

Read More3D Printed Concrete Is Key to This Smart Wall: The Cool Parts Show #40

The SkyBAAM cable-driven 3D printer creates opportunities for embedded functionality in concrete, as demonstrated in this episode of The Cool Parts Show.

WatchFor Velo3D CEO, the Future of Metal AM Is Large Producers

The growing demand for metal part production via additive manufacturing will be met by producers that start small and massively scale, says Velo3D’s Benny Buller. Thus, AM will follow a different path from other part-making technologies.

Read MoreThe First Choice Was Right: How RP+M Succeeded With Production FDM

This additive manufacturing company narrowed its focus onto the 3D printing capability it knew best and the industry sector best able to benefit from FDM production parts. Characterizing and controlling the process was the breakthrough that has led to production work from Boeing and others.

Read More