Articles

Custom Canine Wheelchair From Carbon Fiber-Reinforced PP: The Cool Parts Show #44

A dog with a condition that affects her mobility gets a custom 3D printed wheelchair in this episode of The Cool Parts Show, enabled in part by a new polypropylene filament.

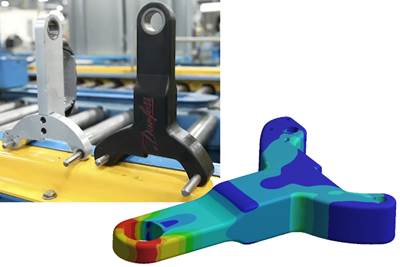

WatchWorkflow Validates 3D-Printed Composite Part Performance

A new workflow connecting 3D printing data with finite element analysis (FEA) enables simulations of fiber-reinforced 3D-printed parts that can predict mechanical and structural performance.

Read MoreVacuum Cycling Nucleation (VCN) Removes Resin, Powders from 3D Printed Parts

Vacuum Processing Systems’ proprietary VCN process is well suited for parts with small holes and tiny passageways. A combination of vacuum and fluid clears uncured resin or unsintered metal powder. See it in action.

WatchObservations on the Development of Additive

An ASTM leader describes the current and changing role of AM for industry.

Read MoreFaster FFF Build Rate Using Rectangular, Variable-Orifice Nozzle (Includes Video)

A new nozzle design plus sophisticated slicer software offer control over layer width in polymer 3D printing while the layer height stays constant.

WatchWhy Inventors and Additive Manufacturing Go Together: AM Radio #13

The ease of beginning to produce at small scales using 3D printing opens the way to a new class of manufacturer: the inventor making their own product.

ListenFinding the Serial Production Wins for Polymer Additive Manufacturing

Aerosport Additive is aiming to grow its serial production work by seeking out the niches where AM materials, costs and capabilities align — challenging the notion that “production” of plastic parts always means molding.

Read MoreAdditive Manufacturing: March 2022

The March edition of Additive Manufacturing is now available! This month's edition covers binder jetting, 3D printed baseball mitts, AM material challenges and more.

Read More3D Printed Heat Exchanger Uses Gyroids for Better Cooling | The Cool Parts Show #43

Replacement heat exchanger for a helicopter is half the size and delivers 4× the cooling, thanks to a geometry that could only be made via additive manufacturing.

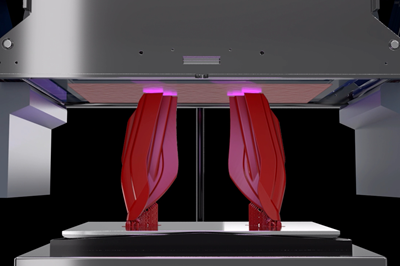

WatchFrom BCN3D, Lithography 3D Printing With No Vat Brings Bigger Scale Plus Viscous Materials

Parts take shape in the open air. Viscous resin is rapidly carried on a laminate to build each layer. LCD screen size, not vat size, is the limit on productivity.

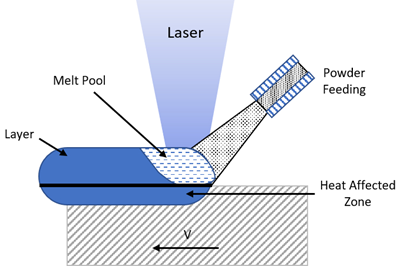

WatchPowder Comparison: Standards for DED Material Substitutes

What powder properties lead to performance similar to a DED powder? Basic flowability energy, particle density and particle morphology are key candidates.

Read MoreUsing (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

Watch