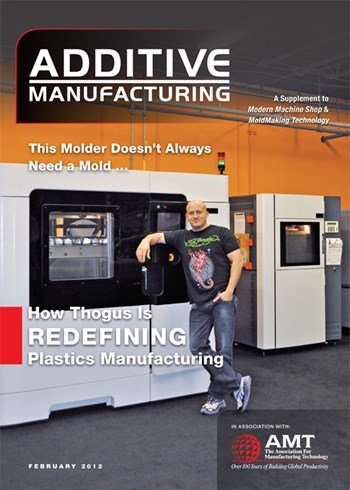

Matt Hlavin (left) founded RP+M when he consolidated the AM capability of Thogus Products Company into a separate firm, which Tracy Albers (right) now leads. Thogus was the subject of the cover story of Additive Manufacturing's first issue (below). We went back to RP+M for an update.

There is, or has recently been, an excess of 3D printing capacity relative to market demand. Matt Hlavin has seen this in the prices 3D printing service providers have been quoting for prototyping and simple, small-batch part production. Those prices have recently trended down.

Jump to the 6 considerations that have helped shape RP+M

Certain things have not changed since we first covered Thogus's embrace of AM in this article 10 years ago. After exploring additional capabilities and letting them go, the manufacturer today continues to lean on FDM.

However, there is no excess in capacity for repeatable, scale-production 3D printing. Prices in this area have held. Margins for this work have held. Hlavin is CEO of 71-year-old, 130-employee injection molder Thogus Products Company in Avon Lake, Ohio, and also founder of the 3D printing business launched by that company, Rapid Prototype and Manufacturing, or RP+M. Today, that newer company is led by president Tracy Albers, and over the years, it has become more and more focused on serving production applications with 3D printing. How many years? A little over 10 — Thogus’s entry into additive manufacturing was the subject of Additive Manufacturing’s first cover story for the debut issue of its print edition 10 years ago. I recently returned to talk to Albers and Hlavin about what RP+M has learned about succeeding with a production capability, additive manufacturing, that is on the one hand now far better established and understood, but on the other hand is, in many ways, still very new.

Ten: Keep that number in mind. What is the difference in difficulty between 3D printing for prototypes and one-off parts versus serving the market for production AM? The answer is a factor of 10. 3D printing service bureaus using fused deposition modeling or fused filament fabrication (FDM or FFF — the two terms mean the same thing) have been found to offer a coefficient of variation, a measure of the scope of a part-making process’s variability, of 25%. Albers was part of the study that found this number (see below). Meanwhile, through the course of various process measurements and controls, RP+M has been able to realize production 3D printing via FDM with a coefficient of variation 10 times tighter, at 2.5%. This is arguably the qualifying threshold for production AM, because this is a level of consistency that established production technologies realize. RP+M has found its role and its most promising opportunities not because of 3D printing, not exclusively this, but more because of systems the company was able to develop for using FDM machines from Stratasys as production units with build-to-build and machine-to-machine repeatability comparable to injection molding machines or machine tools.

It took time to get here. Thogus’s first 3D printer landed in late 2010. (That first cover story appeared at the start of 2012.) This printer was from Stratasys, which back then exclusively offered FDM. Making functional FDM parts was Thogus’s first AM ambition. Other services were later added, including binder jetting for parts related to medical imaging and laser powder bed fusion for tooling. Later still, these added services were abandoned as in-house offerings, because the first idea, production AM in polymer, remained the right idea for this organization that was already so well established in plastics production. Developing this idea would require the separate company under Albers, RP+M; it would require the production system for FDM; and it would require a focus on the industry currently best equipped to benefit from production FDM: aerospace.

A breakthrough for RP+M came with an effort supported by America Makes to identify and control the variables important for repeatability in FDM. Albers says the range of process variation was tightened to one-tenth the variability typical of FDM. RP+M practices the findings of this study, which are now publicly available.

Again, the system was the breakthrough. RP+M had the opportunity to develop a process for repeatable production on FDM machines thanks to its participation in a project led by America Makes, the U.S. government-established national accelerator providing funding and frameworks for public-private partnerships in AM. Production work has followed RP+M’s implementation of the system it helped to author. Now, the company is a production-oriented business that is financially independent of Thogus. That business looks different from a 3D printing service bureau focused on one-offs and prototypes, but in just as many ways, it also looks different from an injection molding business. Based on the lessons Hlavin and Albers have learned, what follows is a picture of that production AM business today, starting with the process.

How Repeatability Improved

From the outset, Hlavin’s aims did not focus on inventing with 3D printing, but rather focused on manufacturing with it. “I haven’t wanted to be the thought leader in additive. I want RP+M to be the process leader,” he says.

RP+M currently has seven Stratasys FDM machines, of varying sizes. Not all of their work is repetitive production. Aerospace production is RP+M's highest-margin work, but it is subject to surges. Remaining responsive to prototyping work helps fill open capacity.

Yet for most of the history of the technology, it has been easier to innovate with 3D printing than to produce with it. FDM in particular was originally applied to prototyping or making non-precision parts. It has always held promise for manufacturing precise components repeatably, but realizing this promise potentially entailed identifying and controlling too many process variables for one company to take on all by itself. Thogus and RP+M came to recognize the scope of this challenge over time. America Makes recognizing it proved to be a vital breakthrough. With Stratasys, America Makes provided a grant to develop production FDM for aircraft component manufacturing using an established material and platform combination, Stratasys’s Ultem 9085 thermoplastic on its Fortus 900mc 3D printer. As an established user of this machine type, as a company aiming toward repeatable production with this machine type, RP+M joined the effort as both a well-equipped and motivated participant.

In fact, there were two grants, at two separate times. Albers also worked on the first, which aimed at the less ambitious goal of characterizing FDM variability. The work, drawing on studies of many FDM users and applications, arrived at the 25% figure for coefficient of variation. A key finding: Personal style in applying FDM was one of the leading sources of process variability. This revealed how much work there was to do in developing a production system around these machines. Consider that practically no one in manufacturing ever speaks of or concerns themselves with personal style in the way that, say, injection molding machines are used.

The polymer AM company is located in the same facility as its parent, Thogus. The latter company's knowledge in plastics postprocessing is often valuable in fulfilling AM production jobs, which practically always involve demands beyond the 3D printing.

The second, later, larger grant aimed at developing the production process specification for FDM using Ultem. Another group involved in this work was NIAR, the National Institute for Aviation Research at Wichita State University. While RP+M worked on machine-related parameters for production, NIAR studied and qualified the consistency of the material production. In the case of RP+M’s half of the work, the starting point was brainstorming: What are all of the settings and conditions within the machine, and environmental factors outside the machine, that might be significant to the outcome of the process? Once this list was articulated, the work — considerable work — involved controlled experiments in changing each of these variables to measure the effect, and the optimal range of control over that variable that production 3D printing on this FDM platform requires.

Now, that work is done. The resulting process specification has been published as NCAMP (National Center for Advanced Material Performance) Document 89085. As originator of the specification, RP+M is a confident practitioner of it — a distinction the company has been able to demonstrate to the satisfaction of Boeing and Lockheed Martin, two aerospace OEMs now running part production work through the company.

But even this specification is really just the beginning. It assures a formula for production, not necessarily the way to form the business and procedures around this formula. For RP+M, the way forward therefore has also involved many other considerations in refining and developing the company and its work. They include all of these:

1. Remaining Responsive to Prototyping

“Our workload for production parts comes in surges,” Albers says. It can fill machine capacity, and then there are periods when machine capacity is open. Part of staying viable for production therefore means meeting opportunities outside of production as well.

Why surges? Multiple reasons. Some of the aircraft part production involves legacy parts formerly made conventionally for which a supplier comparable to the original producer no longer exists within the aircraft company’s network. These parts are ordered not according to production schedules, but according to the stocking needs of a service group.

Meanwhile, both new and legacy parts intended for additive go through long delays before the part is approved for production. Albers believes she knows what is happening in these cases. AM is so new, it takes many internal conversations before the OEM’s stakeholders reach the consensus that 3D printing is acceptable for production.

The result of both of these circumstances: Work for RP+M, even significant work, has a way of coming out of the blue.

Meanwhile, a company needs cash flow. Remaining in the prototyping business, remaining good at this, is one way to assure a leveling of income. While I was visiting, Albers looked at a one-off job running on one of the machines: a prototype for a furniture maker’s new chair. Precise production it was not, but still a valuable part of the business.

2. Few Employees

RP+M’s exploration of possible opportunity over the years has ranged to include multiple AM markets, multiple industry sectors and multiple AM processes, including metal. At its peak staffing and not counting anyone from parent company Thogus, the company had 18 employees.

Now there are four. Focusing on one purpose — plastic part production for aerospace via fused deposition modeling — has allowed RP+M to pare down necessary duties and dramatically reduce staffing.

Staffing will grow again as production work and the number of machines grows. But at its current level serving two major aerospace OEM customers with seven FDM machines, says Albers, “Four people who really get it is all we need.”

Machines outnumber employees at RP+M. Focusing on a niche, FDM for aerospace parts, has allowed the company to tighten staffing. "Four people who get it is all we need," says Albers. One of those employees is production manager Cameron Rogers, speaking with me here.

3. Ownership of Maintenance

With regard to maintaining its machines, RP+M has had to become precisely like its injection molding parent: It performs its own machine service and repair.

An injection molder cannot wait for an outside machine service technician to repair an idle machine. Production 3D printing faces the same uptime demands. The RP+M team has had to acquire the skill and tools to keep its FDM machines serviced and running.

4. ERP Like a CNC Machine Shop

Parent company Thogus relies on an enterprise resource planning (ERP) system to manage production, but the software providing this oversight for injection molding actually proved to be an awkward fit for RP+M. In terms of pacing, quantity and output, 3D printing via FDM is more like the work of a machine shop than an injection molder. So RP+M abandoned Thogus’s system to instead adopt an ERP system (from Shoptech) that is tailored to machine shops.

5. Cold Water on Some Prospective Customers

Prospects for additive manufacturing work are sometimes driven by a desire simply to try this new(ish) manufacturing method, or even just by the sense of wanting to explore something “high tech.” The part in question may not be a good candidate for 3D printing. Many manufactured parts — arguably most manufactured parts — can be more economically made through conventional methods such as molding or machining.

Albers says her frequent response in cases like this is to say, “I’ll be happy to quote you on this job, but you’ll be offended.” The price to mass-produce a part through AM that is not suited to AM can be shockingly high.

Even the parts well-suited to AM depart from the economics that govern other types of production, she notes. “A customer might ask: Will you give me a discount if I order 200,000 pieces?” The answer is, perhaps surprisingly, no. It has to be no, because the per-part costs of AM do not decrease with quantity. With other manufacturing methods, the per-part cost of tooling and setup can be reduced if that investment can be applied to more units. But: “In additive, there is no tool!”

6. Can-Do Attitude

“We just say yes,” Albers says. This, too, has proven to be a powerful tactic for advancing additive manufacturing into production.

A production AM part almost always entails additional details apart from 3D printing, and downstream from this step. Thogus’s plastics experience provides valuable knowledge in the area of postprocessing polymer AM parts, but the considerations can also land outside this experience, perhaps necessitating outsourcing. One AM part for Boeing demanded a sheet metal component neither RP+M nor Thogus could make to match the needed precision. Finding the right just-in-time supplier of the fabricated metal subcomponent became paramount to delivering the job.

“We will figure it out,” she says. This is the assumption the company has to make. It is the only way to win and carry out production jobs, she says, and therefore it is the only way for AM to obtain the most profitable opportunities. Prototyping and one-off work is far more likely to consist mostly or entirely of 3D printing, free of additional demanding steps or components. But additive manufacturing — production additive manufacturing — routinely consists of not just 3D printing but also other important steps.

In some cases these steps are perplexing when RP+M first takes the job, but those steps can’t be allowed to be a barrier to accepting the work.

Noting the prototype running in one of the printers, Albers says, “You need a can-do attitude, or you’ll end up doing nothing but simple, lower-margin work every day.”

Related Content

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreRead Next

The Race to Faster, Cheaper and Better AM for Aviation

An aviation industry partner called NIAR may be the largest institute you've never heard of. But through a new materials and process database for additive, it’s promising to help aviation manufacturers produce AM parts faster, cheaper and more reliably than ever before.

Read MoreBoeing Qualifies Stratasys’ Antero 800NA for 3D Printed Flight Parts

Enhanced chemical resistance and fatigue performance of the PEKK-based material provide Boeing with a new, high-performance option for polymer flight parts.

Read MoreOil Collector Upgrade for Legacy Helicopters Is a 3D Printed Pathfinder Part

The lightweight part was delivered faster and made more easily via electron beam melting (EBM) than a conventionally manufactured alternative could be produced, while also illuminating a way forward for upgrading other existing systems.

Read More