“Our vision is a solutions house approach,” says Ed Thomas, 3D printing business development manager for Lubrizol. “We need to be agnostic to material and 3D printing technology, to support our customers from sketch through finished product.”

This is the kind of statement one might expect from a contract manufacturer, a company with engineering expertise and 3D printing capability seeking to develop work for production additive manufacturing (AM). To hear it from Lubrizol, a decades-old supplier of TPU polymers including additive manufacturing grades, is striking.

But the intricacies of AM and 3D printing technologies have driven the company to take a different approach to serving this marketplace. In additive manufacturing, it is no longer enough for a materials supplier to be just a materials supplier, the company believes. In fact, the best way to advance AM materials into applications may be to take that solutions house approach — to develop and implement materials in conjunction with technology and design knowledge, in service of specific end-use applications. It’s a strategy that is serving the company well, and one that could be key to driving AM forward.

Not Just Another Market for Thermoplastic Polyurethane

Headquartered in Wickliffe, Ohio, Lubrizol is one of the largest manufacturers of thermoplastic polyurethane (TPU) in the world, offering this material in a diverse selection of grades and formats. Its TPUs are found in products ranging from sneaker outsoles to cable jacketing to flexible fabrics. The company first entered the additive manufacturing space as a filament supplier in 2017, and in 2019 introduced its Estane 3D TPU M95A formulated for the Multi Jet Fusion 4200 series from HP. At the outset, 3D printing seemed like just another potential application for this class of materials, but the company has come to find that AM has different demands than other industries it serves.

“We saw no other way to maximize the value 3D printing can bring to the end user.”

Lubrizol’s activities in the space today are wide-ranging. The company’s 3D printing applications development takes place in Montmelo, Spain, and Brecksville, Ohio, as well as Loveland, Colorado, the site of contract manufacturer Avid Product Development, which Lubrizol acquired in August of 2020. Building on its long history as a materials company, Lubrizol is now also a parts provider though Avid — a move it has not made with any other production technology, but one that it has found is necessary for advancing with additive manufacturing.

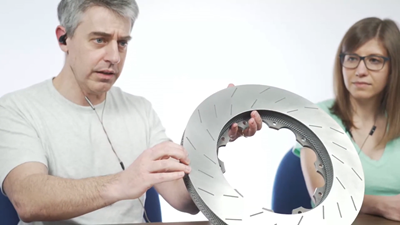

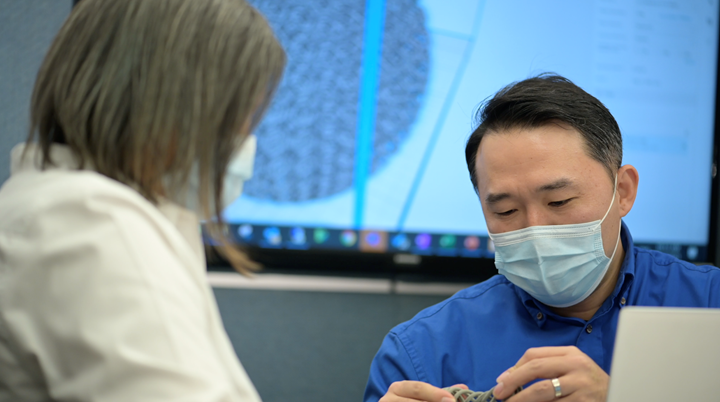

Peter Jung, Lubrizol 3D Printing Solutions Technology Development Manager, evaluates a part’s performance properties.Photo Credit: Lubrizol.

“We saw no other way to maximize the value 3D printing can bring to the end user,” says Peter Jung, 3D printing technology development manager. “We had the materials expertise, but we were missing design for additive manufacturing [DFAM] and large-scale 3D printing production capability.”

The deeper Lubrizol got into additive manufacturing, the more clearly it saw these gaps. The challenge it came to understand is less one of material formulation, and more a question of how to apply these materials effectively with additive.

“The materials are suitable, but we had very little DFAM experience and that doesn’t play to AM’s strengths,” Thomas says. “Our learning curve came in design.”

In additive manufacturing, design and material can work together to deliver a variety of results even within the same part — like the living hinge seen here. This custom packaging and electronics enclosure was designed, printed and assembled by Avid. The packaging is made from Lubrizol Estane 3D TPU M95A, a non-marring material suitable for Class A surfaces. Photo Credit: Lubrizol.

The Design Learning Curve

In order to provide the best solutions for additive manufacturing, it became evident that Lubrizol would need to get familiar with the additional challenges of production AM; the actual products and parts being made this way; and methods for achieving desired results through manipulating design. Rather than become an expert additive manufacturer outright, the company chose to pursue this expertise through the acquisition of Avid Product Development.

Why Avid in particular? Lubrizol evaluated a group of potential contract manufacturing candidates, and ultimately chose Avid Product Development for its years of product development and production via additive manufacturing, as well as its experience with a range of polymer 3D printing processes and ability to start from scratch to develop parts specifically for 3D printing. The company uses multiple 3D printing modalities including stereolithography, digital light processing (DLP) and MJF. In Avid Product Development, Lubrizol gained an affiliate with insight not just into how to apply each process, but how to optimize it through print parameters and part design.

...there may be geometric solutions to problems that until now have been characterized as materials challenges.

It’s this last point that is particularly interesting, for both Lubrizol and its customers. Whereas other suppliers serving additive have approached materials as an R&D hurdle to be overcome with an expanding portfolio, Lubrizol has come to understand that there are viable existing materials with potential still yet to be unlocked through design for additive manufacturing. In other words, there may be geometric solutions to problems that until now have been characterized as materials challenges.

This shock absorber highlights the interoperability of various 3D printed materials as well as design possibilities with additive manufacturing. The part features a PA11 coil spring and multiple components produced in PA12, as well as panels that highlight different postprocessing techniques. The absorber was designed, manufacturing, postprocessed and assembled at Avid. Photo Credit: Lubrizol.

Design Expands Material Applications

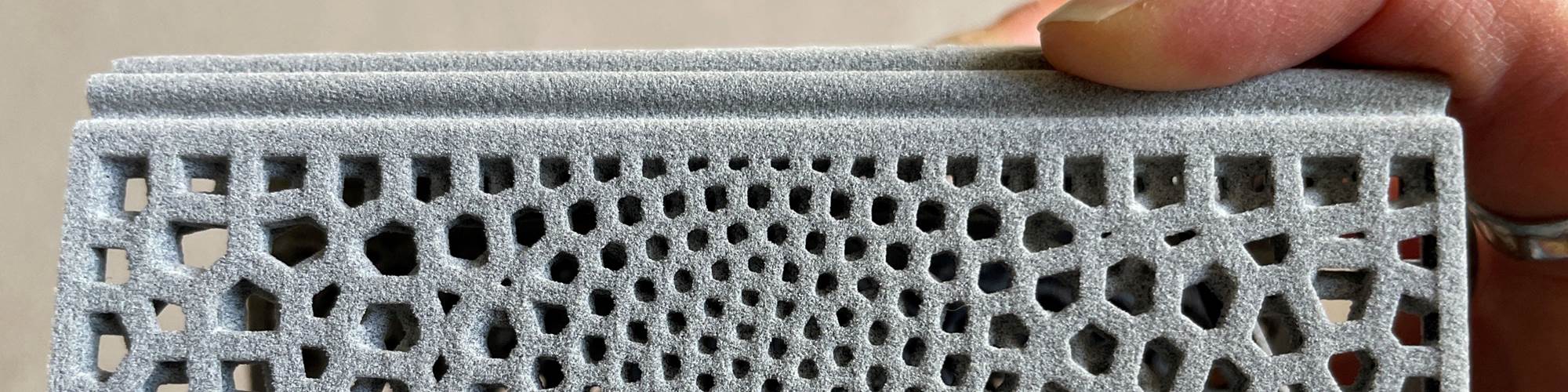

From Lubrizol’s perspective, this design freedom is AM’s untapped superpower. TPU alone can achieve an array of different characteristics from similar or even the same formulation just by manipulating elements such as lattice cell shapes or strut sizes, but it takes 3D printing prowess and exposure to real applications to learn to apply these principles. While new material formulations will continue to be developed for 3D printing, they will always need to work in conjunction with design as well as the production method.

One example that illustrates the material-design-printer dynamic is VarioShore TPU, a ColorFabb product that is based on Lubrizol resin. The TPU filament is an “active foaming” material that expands as it is printed, activated by the heat of the nozzle. Printing temperatures in the range of 200 to 250°C will cause the filament to expand up to 1.6 times its original volume and become softer; below this range, the material will not foam. Prints using this material can vary in durometer across their geometry, delivering cushioning or flexibility in some areas but greater rigidity in others — meaning that just one filament can fill a variety of possible application needs.

The material is currently being applied by a ColorFabb spinoff to make insoles for diabetics, who require specific areas of support in their shoes. But this is not the only use for VarioShore TPU; the impact-resistant material could also be applied for prosthetic liners, crutch grips and other custom assistive devices, granting designers endless possibilities for customization through variable flexibility alongside 3D printing design freedom. The material exemplifies what can happen when material, design and printer work together: an incredible diversity of material properties in the same print, derived from a single material.

“We haven’t exhausted all the existing material capabilities.”

While VarioShore TPU is a newer product, Lubrizol sees other opportunities to apply existing materials in a similar fashion. Design capabilities can provide for customization of medical devices and footwear, for example. 3D printed TPU materials can replace high-density foams in protective gear, and by varying the lattice infill even provide better shock absorption than conventional materials. Working closely with Avid Product Development and partner companies engaged in production work helps Lubrizol better understand production needs and when and how to apply materials like this, so that each new problem doesn’t necessarily require a new materials solution.

“Many solutions that customers are looking for could likely be solved with design,” Jung says. “We haven’t exhausted all the existing material capabilities.”

Related Content

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Materials are Key to 3D Printed Injection Mold Tooling

IC3D’s combination of experience with filament production, building 3D printers and service bureau work is helping it expand the possibilities of 3D printed injection mold tooling.

Read MoreMaterial Innovation Is a Powerful Freedom of AM: Here Are Examples

Possibilities that were speculative a few years ago are coming true today. Applications of metal matrix composite provide an example. Recent articles explore the ongoing advance of 3D printed materials.

Read MoreCustom Heels Are a Step Up for Circular Fashion, Sustainable Manufacturing

Custom shoe company Hilos demonstrates how, with additive manufacturing, relative outsiders can not only launch a product, but implement a new production mindset into an established industry. The company is bringing comfort and customization to fashion footwear with sustainable, on-demand production based on 3D printing.

Read More

.jpg;width=70;height=70;mode=crop)