Articles

Sustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

Read MoreHow Production Looks Different for 3D Printed Furniture Manufacturer Four Years Later: AM Radio #50

Furniture manufacturer Model No. has shown that there is a demand for customizable, sustainable 3D printed tables, chairs and more since we last covered the company in 2020. But today, production looks different.

ListenOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read MoreThe 3D Printed Part Protecting Drivers in the Indy500

The 108th running of the Indianapolis 500 takes place on May 26. This year, the cars on the track feature a new 3D printed component: the next generation of the titanium top frame that holds the aeroscreen and protects the driver in the event of a rollover.

Read MoreVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

WatchMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read More3 Attributes of the “Second Wave” of AM Part Producers

Successful contact manufacturers in additive look more and more like successful contract manufacturers in general.

Read MoreNPE 2024: Additive Manufacturing Assisting, Advancing the Plastics Industry

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

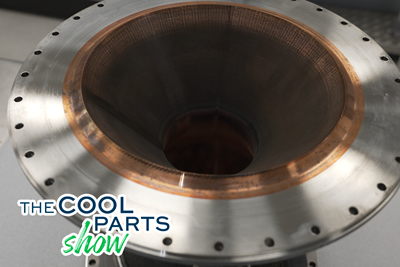

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

WatchCryogenic Tanks for Space Refueling: The Cool Parts Show All Access

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

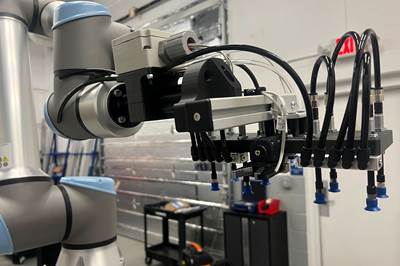

WatchRobotics Integrator Leverages 3D Printing for Faster Automation Deployment

Rapid Robotics helps manufacturers get up and running with automation quickly, by providing robots that arrive pretrained and already equipped with tooling which is often 3D printed.

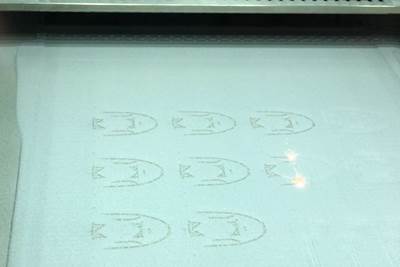

Read MoreAdditive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

Watch