Share

NPE: The Plastics Show returned for the first time in six years, bringing plastics manufacturing technology to Orlando, Florida, May 6-10, 2024. In the interim since the previous edition of this trade show, additive manufacturing’s adoption in plastics has advanced and expanded. While AM technology lacked a centralized footprint within NPE’s two exhibit halls, its presence was felt throughout the show, from the 3D Printing for Plastics Processors Workshop held on Wednesday to material- and technology-focused exhibits scattered throughout the exhibit floor.

In each case, additive manufacturing was presented less as an industry disruptor, and much more as an aid to toolmakers, molders and OEMs, and a means to augment what these companies are already doing. Here are a few of my takeaways from the show:

1. AM is one way of meeting workforce challenges in toolmaking.

Metal 3D printing offers a faster way to obtain injection mold inserts, such as this mold slide for an automotive trim tool 3D printed with Mantle’s technology. Printing this slide required only 4 hours of active labor from the customer’s toolmakers, versus several hundred hours to produce it conventionally.

Many experienced toolmakers are retiring or near to it, and “There’s no second bench,” as Mantle co-founder and CEO Ted Sorom puts it. Additive manufacturing technologies like Mantle’s TrueShape process (a technique that builds tooling by extruding, milling and then sintering metal paste) are gaining traction because they can consolidate workflow steps to produce mold inserts. Mantle’s process, for example, often reduces or eliminates the need for sinker EDM operations (and the associated tooling). Avoiding or reducing the time spent on process steps like this enables toolmakers to be more efficient in their work, and shortens the time line from insert design to use.

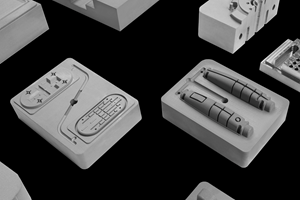

Xact Metal highlighted other potential benefits of 3D printed metal tooling with this insert. Leaving areas open enables printing this tool faster and with less material; supports cooling in injection molding; and also enables faster press operation due to lighter weight.

The prevalence of 3D printing technology in the mainstream may also help with recruiting the next generation of toolmakers. Xact Metal, which showcased the tooling production capabilities of its laser powder bed fusion platform (described in more detail below), sees 3D printing as an aid to reshoring manufacturing as well as meeting workforce challenges. “Kids today know 3D printing,” says Scott Kraemer, application engineer, “and bringing this technology into this space could entice them into a career in toolmaking.”

2. Speed is driving adoption.

This mold insert for an automotive suspension ring is 3D printed from BASF’s Ultracur3D RG3280. The tool was produced in about 12 hours with 3D printing, versus about 6 weeks to source a conventional tool cut from aluminum.

Contract manufacturers and OEMs are seeing additive manufacturing “win” when it can provide the fastest route to a part or tool. Material supplier BASF showed several sets of mold inserts in its booth printed with a ceramic material called Ultracur3D RG3280 intended for SLA and DLP-style printers. The chemistry of the slurry makes it possible to achieve a usable injection mold tool with just a short 10- to 15-minute UV cure to crosslink and densify the material, says David Constant, sales and business development manager for BASF 3D Printing Solutions North America. A longer heat treat can be done as a secondary step, if necessary, but avoiding this lengthy procedure (often 7 hours or more) helps to accelerate mold creation such that turnaround time on a new molded part can be as little as 24 hours.

For contract manufacturers such as Xometry, additive manufacturing enables faster on-demand manufacturing and product development. New designs can be iterated in a “shotgun approach” in which multiple designs are 3D printed at once to quickly arrive at the best choice, says Greg Paulsen, director of applications engineering and marketing, in his presentation during Wednesday’s 3D Printing for Plastics Processors Workshop.

The break-even point between direct polymer 3D printing and injection molding depends on a number of factors, including the part’s design, dimensions and ability to be nested within a build volume, as Greg Paulsen illustrated through several examples. Slide: Xometry

Other speakers at this event emphasized the speed at which 3D printing can deliver end-use polymer parts, not necessarily as a competitor to injection molding but to support applications that would be time-consuming or expensive to mold. Daniel Baker, program manager for plastics at Endeavor 3D, shared a case study in which his company delivered a short run of about 500 parts for a new high-end gaming controller still in development, which would have suffered a long lead time waiting for injection molding. Andrew Roderick, senior applications and sales engineer for Extol, described how his company 3D printed 53,000 automotive parts over three months in a bridge production application to prevent the shutdown of the customer’s assembly line. Spencer Loveless, founder and CEO of Merit3D described how his company manufactured 62,000 binocular case tether components in just 7 hours, delivering the parts more quickly than injection molding and saving the customer about $300,000 in potential tooling costs.

3. Additive is advancing with partnerships.

One of just a few 3D printing machines physically present on the show floor was Xact Metal’s XM200G2, a laser powder bed fusion printer which is positioned for accessibility. The machine is small enough to fit through a standard doorway, runs on 110-V electricity and offers a compact build volume that keeps operating costs down by limiting how much powder is needed to fill the bed and how much argon is required to keep the environment inert. But, just to the right of this 3D printer was a postprocessing machine, a DLyte electropolisher from GPAInnova, one of Xact Metal’s equipment partners. The company has found that, while some buyers want to research and choose their own auxiliary equipment, 3D printer adoption (and sales) can be eased by offering customers a more complete package of equipment.

While 3D printing was scattered across the show, most AM-focused exhibitors could be found in the Advanced Manufacturing Zone. Xact Metal’s booth included both support equipment, in the form of the polishing machine seen in the foreground, and its 3D printer, located just beyond.

“There’s a solution for everything out there, from software to polishing to auxiliary equipment,” Kraemer says. Xact now has relationships with a number of other companies whose products it can recommend to customers — including materials. The company recently announced a new partnership with Uddeholm to supply the latter’s Corrax tool steel in powder form.

“Toolmakers are used to making tools from Corrax billet,” Kraemer says. “Now they can 3D print with it, too.”

4. 3D printing still has a significant support role to play.

While mold inserts and directly 3D printed polymer parts were the primary areas of emphasis for AM at NPE2024, the technology is also helping manufacturers achieve other benefits in their operations. In one conversation at the show, I spoke with a member of a new additive manufacturing services company which is specifically targeting the jigs and fixtures market for clients with large factories and assembly lines, seeing this as an underserved market.

In another meeting, I talked with team members from automation technology company Universal Robots and its partner EMI Corp. about the ways in which 3D printing is enabling the adoption of collaborative robots, or cobots.

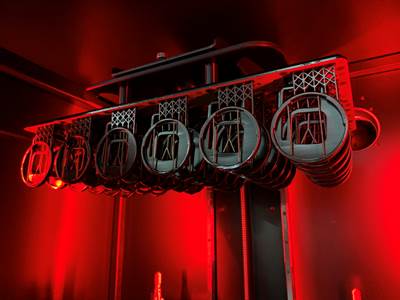

Additive manufacturing also has a role to play in aiding the adoption of other technologies. This demo in the Universal Robots booth combines a UR cobot with a vacuum gripper, part nests and other 3D printed integration elements produced by EMI Corp.

“Peripherals are the challenge,” says Travis Langford, channel and business development manager at Universal Robots. “It’s the interface between the robot and the machine, the safety measures, the end-of-arm tooling.”

To solve the latter challenge, UR often works with and recommends EMI’s services. The company, which supports automation through many services, has been applying Multi Jet Fusion (MJF) 3D printing primarily in nylon to supply automation peripherals such as cable management brackets, part nests and vacuum grippers. According to George Baker, EMI regional sales manager, the 3D printing technology from HP is cost-effective, helps to reduce the weight of peripherals and enables accelerated lead times.

“3D printed tooling helps robots get installed,” Langford says. “Solving that interaction helps automation move forward.”

Related Content

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreRead Next

How Flowable Metal Paste Could Deliver on 3D Printing's Promise for Mold Tooling

A new 3D printing process that shapes extruded metal paste before sintering can produce fine detail and surface finish suitable for injection mold cores and cavities with limited or no additional postprocessing.

Read MoreAfter Years in China, 3D Printing Lets Vacuum Accessory Maker Develop U.S. Production

The costs of injection molding had Dustless Technologies making tooling and many parts offshore. Additive manufacturing promises an alternative, as in the case of the company's newest product, which is entirely U.S.-made.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More

.jpg;width=70;height=70;mode=crop)