Founded in 2019, Rapid Robotics Inc. (San Francisco, California.) has a novel business model for helping manufacturers automate their operations quickly and at modest cost. The company’s focus is on deploying affordable, pretrained cobots — produced by robotic partners Yaskawa Electric Corp. and Universal Robots A/S — that can perform dozens of simple mechanical tasks like packaging/boxing and inspection while meeting high-quality standards at a fraction of the cost of traditional robotic solutions or human labor.

The company notes that many factors have slowed implementation of robotics and other automation in manufacturing over the decades, including complexity of adoption, challenges using equipment correctly and the fact that most robots tend to be limited to a single purpose, which, if the needed task changes, can consign that robot to a storage closet.

With all the cost pressures manufacturers currently face, there is an urgent need to make automation faster, easier and less expensive to deploy. Furthermore, increasing automation can make it easier and more attractive for millennials, “zennials,” women and other underrepresented groups to seek job opportunities in manufacturing.

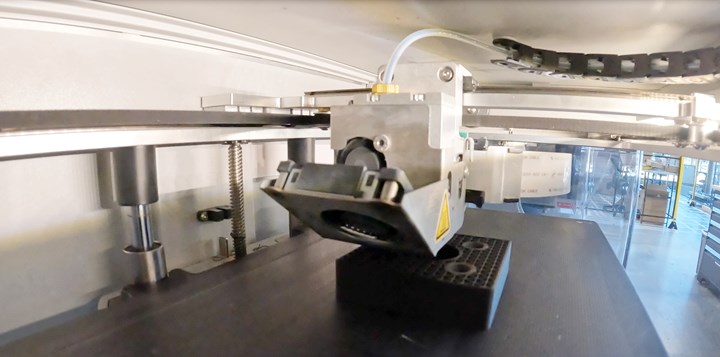

At Rapid Robotics’ San Francisco headquarters and Novi, Michigan, U.S. facility, automation cells are designed, cobots are programmed and their end effectors are built before shipping to customers. At both locations, engineering teams prototype concepts for EOAT and other manufacturing aids on FDM/FFF printers. Once designs are production ready, durable components are produced on banks of Markforged carbon fiber composite printers. Photo Credit: Rapid Robotics Inc.

Rapid’s out-of-the-box offering — which includes its rapid machine operator (RMO) software platform and wheeled cobots that can be rolled from one location to another — enables a manufacturer to deploy a cobot within hours (rather than weeks), greatly reducing disruption to manufacturing operations while permitting companies to achieve ROI within months, thereby helping make automation affordable to more and smaller companies for the first time. Moreover, cobots can be redeployed to new tasks just as quickly without the manufacturer needing expert personnel with programming or robotics skills, or requiring systems integration or specialized hardware. Reportedly, a single operator can supervise up to eight cobots simultaneously using a computer tablet. Customers hail from the automotive, packaging, medical device, and plastic and metal part production segments.

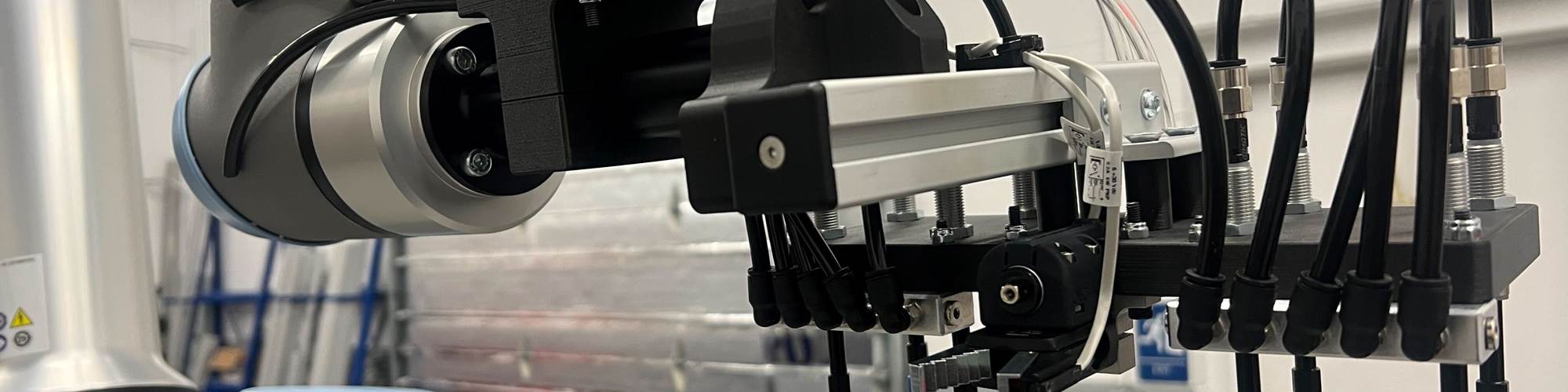

To keep automation systems affordable and cobots lightweight — which is critical to overcome their inherent payload constraints and make them safer to operate alongside humans — Rapid has used polymer AM technology since its beginning. Typical printed end-of-arm tools (EOAT) include gripper components, fingers and the platforms on which these tools sit.

“What we design and print is highly dependent on the type of task we’re trying to automate,” Forest Lee, Rapid director of brand narrative, explains. “While it’s possible to find off-the-shelf part pickers and grippers that could work, often standard offerings aren’t the right size, or they aren’t durable enough to operate in hot or dusty environments, or they’re heavier than what we can print ourselves. Weight is important as it affects the speed at which our cobots operate and that, in turn, impacts cycle times for the process we’re trying to automate. Hence, we use a lot of purpose-printed components that meet our strict reliability standards. Our goals are to be as non-disruptive to customer operations and to deploy as quickly as possible. With additive manufacturing, we have great flexibility, can prototype and produce parts faster and more efficiently and that enables us to build systems JIT [just in time]. Everything we do to make our automation solutions more efficient matters.”

The Rapid team takes advantage of additive’s ability to print lattice structures, which are lighter yet produce stronger structures, print faster, use less material and are less costly than solid structures. This permits each cobot to carry a bit more payload, move faster and operate with greater safety around humans. Shown above is an EOAT being printed using the lattice technique. Photo Credit: Rapid Robotics Inc.

Lee adds that injection molders are an important segment for the company, where cobots not only help demold parts but also cut sprues and box parts, thereby reducing cycle time, manufacturing footprint and the cost of integration.

“Serving parts to robots can present significant challenges, since robots have limited reach, and often there is a limited footprint in which an automation system can fit, which makes conveyance solutions to serve those robots costly to customers and often adds significantly to cycle time,” he continues. “Since we’re not relying on off-the-shelf solutions, we can be more innovative and deploy faster and more efficiently at lower cost. For instance, we can give a robot two ‘hands’ in two different locations that enable it to pick up more objects and stack one on the other for greater efficiency. This is complex and difficult work and there aren’t a lot of other robotic providers offering it.”

More From This Author

Peggy Malnati is a Detroit-based contributing writer for CompositesWorld magazine, for which she primarily reports on automotive and ground transportation. SUBSCRIBE HERE

Related Content

Mantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreQ&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

Read MoreRead Next

Savage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.

Read More3D Printed Conveyor Mat Aids Automation: The Cool Parts Show #55

Additive manufacturing for long, flexible sections of brush material? On this episode of The Cool Parts Show, how a continuous DLP system provides the answer for a component critical to vibratory automation systems.

Read MoreLaser-Sintered Grippers Solve Robotic Packing Challenges

Additive manufacturing produced lighter, stronger vacuum grippers for robots on a food packaging line.

Read More

.jpg;width=70;height=70;mode=crop)