Share

Read Next

Shopping through online storefronts — whether for business or personal purchases — has become the norm, as has the expectation for some level of customization for many products. Some choices, such as a standard size selected from a limited list, can be easily supported by today’s e-commerce platforms. But truly custom products that come in nonstandard sizes or support a wide range of configurations are difficult to offer this way. Purchases of everything from replacement knobs to industrial pumps can be held up in the ordering stage because of this challenge.

“It can take months just to quote a complex product,” says Mac Cameron, founder of software-as-a-service (SaaS) and online marketplace Spokbee. “Any changes involve a salesperson going back to the customer, taking their changes to engineering, and then re-quoting the whole job.”

Quoting a piece of industrial equipment, custom medical device or even a storage cabinet like this (with a variety of sizes, drawer configurations, colors, and options available) can demand considerable back-and-forth discussion to arrive at a quote. Source: Spokbee

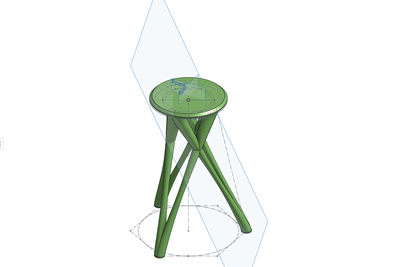

Spokbee, founded in January 2022 initially as a platform to enable a marketplace of customizable 3D printed parts, has since morphed to fill this niche. Cameron cofounded the business with his wife, Karina Cameron, a software developer, initially building a parametric design-based storefront on top of cloud-based CAD from OnShape, developed by PTC. When I first spoke with Cameron in the summer of 2022 the promise was largely confined to the realm of additive manufacturing. He saw the marketplace platform as a design enabler that would allow the average person to select and customize products that could then be distributed to manufacturing partners for 3D printed production.

Beyond Additive Manufacturing

One current client is Alba Racing, a manufacturer of all-terrain vehicles (ATVs) and utility task vehicles (UTVs). Spokbee has developed configuration tools for designing fractal wheel rims, enabling the company to prototype these parts ten times faster. The Spokbee platform has also enabled the company increase the amount of in-house 3D printing by ten times. Source: Spokbee

One current client is Alba Racing, a manufacturer of all-terrain vehicles (ATVs) and utility task vehicles (UTVs). Spokbee has developed configuration tools for designing fractal wheel rims, enabling the company to prototype these parts ten times faster. The Spokbee platform has also enabled the company increase the amount of in-house 3D printing by ten times. Source: SpokbeeThis is still a promise for the platform, but it has expanded beyond items meant to be produced additively into other types of configurable and custom-made products, manufactured through a range of different methods. Additive manufacturing is now just about one-fifth of the business. The Spokbee 3D Configurator, the company’s software tool for its Configure Price Deliver (CPD) service, is scalable to address everything from simple 3D printed parts to complex industrial machinery. Today, it is being applied for everything from 3D printed jewelry to fabricated sheet metal components to custom-engineered hydraulic presses — and bringing the same streamlined, easy-to-use experience for nontechnical buyers as originally envisioned at the company’s founding.

“It does require a lot of work up front to make this work,” Cameron says. “Designs have to be built essentially perfect — meaning they are fully parametric and fully defined.”

All this groundwork is what enables the configurator to present buyers with real-time renderings and accurate quotes. Spokbee has invested in hiring skilled and efficient CAD designers to create these “perfect” files for each product; there is an up-front development fee for launching each new product through the tool, and then clients pay for the platform as a service going forward.

A storage cabinet similar to the one pictured above, as it would have appeared in the Spokbee configurator tool. Instead of back-and-forth between the customer, salesperson and engineering team, all configurations are readily available and the quoted price is updated in real time based on modifications. Source: Spokbee

And while Spokbee still offers some of its own products in the marketplace on its website, its primary business now is supporting those custom configurators for clients. One public customer is Stor-Loc, a manufacturer of configurable tool and storage chests. In the past, sales of custom chests were time-consuming because of the work involved in designing and pricing out the specific configuration of cabinet size, drawers and other options desired by each customer. Now, all the allowable options are represented through the Spokbee 3D Configurator so that buyers can actually visualize the specific product they are ordering and receive an accurate price in real time. More than 10,000 new, previously unmarketed Stor-Loc products are available through the platform.

“Many companies are working off outdated and incomplete product catalogs,” Cameron says. “With the Configurator, we can show infinite versions of the product and accurate pricing. Revisions that used to take months can be done in seven seconds.”

3D printed fractal wheel rims for Alba Racing vehicles, designed through the Spokbee platform. Each new iteration can be created in just a few seconds, dramatically reducing time spent in development or customization of a product. Source: Spokbee

Faster Quotes for Faster Production

In some cases, the time it takes to quote could be a matter of life and death. Take, for instance, surgeries. Many procedures rely on one-time-use devices that have to be configured specifically for the patient. The design process can require substantial back-and-forth as the salesperson meets with the surgeon, conveys the needs to the engineering team (often by marking up a physical drawing), brings a demonstration product back to the surgeon, and then either sends the item into production or repeats the process to execute changes.

The development and quoting process can take so long that, in one example Cameron shared with me, a medical device company was frequently experiencing moments when it was forced to temporarily halt sales and production — and therefore hold up surgeries — because of its backlog of waiting quote requests.

With a digitized configurator such that Spokbee is enabling, much of the complexity of the process can be streamlined; a salesperson could help the surgeon customize the product in real time through the web browser and generate an accurate quote on the spot, and then send the manufacturing files straight through to engineering. Regardless of the product or manufacturing method, streamlining the customization and quoting steps speeds the rest of the production process.

“There is a burning need for this,” Cameron says. “That’s why we are a ‘Configure Price Deliver’ platform now.”

The company intends to keep enhancing the platform, with future plans to integrate both AI-driven design assistants and machine learning algorithms to streamline configuration and deliver more personalized product experiences.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read More7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

Read MoreRobot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreRead Next

To Scale Additive Manufacturing, Separate Design and Production

Spokbee’s online marketplace is designed to ease the launch and sale of customizable, 3D printed products. Its flexibility comes from cloud-based CAD and a distributed network of service bureaus for production.

Read MoreIn Additive Manufacturing, Is There a Case for Separating Design From Production? AM Radio #25A

Design and 3D printing must inform each other, but keeping them under separate ownership can benefit the designer, the producer and the consumer. More in this podcast episode.

Read MoreSustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

Read More

.jpg;width=70;height=70;mode=crop)