Articles

The Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read More4 Weeks from Design to Molded Part for Medical with Metal 3D Printed Tooling

Mold builder Westminster Tool applied the Trueshape process from Mantle to produce tooling to take a medical device from prototype mold to full-scale production in a matter of weeks.

Read More4 Weeks from Design to Molded Part, with 3D Printed Tooling

Mold builder Westminster Tool used Mantle’s TrueShape metal 3D printing technology to develop tooling that it then applied to injection mold more than 7,000 medical parts for its customer, in less than one month.

Read More5 Observations From Dr. Tim Simpson About the State of Additive Manufacturing So Far

The outgoing co-director of Penn State’s CIMP-3D takes stock of how far AM has come, aided in no small part through the work of the organization he helped to lead.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

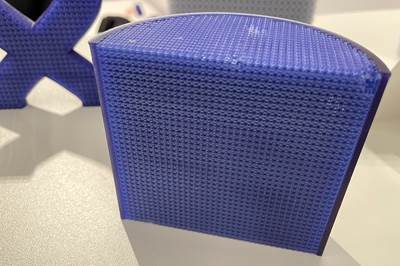

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read More3D Printed Airless Basketball Now for Sale

Wilson began selling its Airless Gen1TM 3D printed basketball on February 16, 2024. Here’s what we learned about the ball last year, in this bonus episode of The Cool Parts Show.

Read MoreTitanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

WatchMore on 3D Printed Ducts: Optimizing for Airflow

Once air ducts transition to AM, the next step is using the physics of airflow to optimize the design.

Read More