Scroll to unlock this premium content if video does not play.

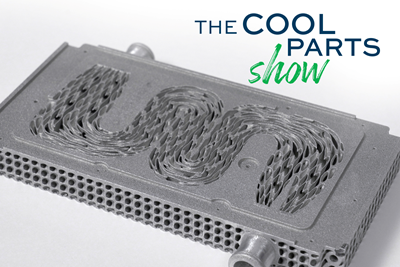

The IndyCar racing series (which includes car races such as the Indianapolis 500) mandated a new safety component on its cars beginning in 2020: the top frame. This titanium piece sits in front of and above the driver to protect him or her in the event of a crash, and holds in place the aeroscreen, a protective windshield that deflects any debris that might injure a driver on the track. The top frame was developed on a rapid timeline that only 3D printing could support. But now, the second generation of this component takes the capabilities of additive manufacturing further, leveraging AM for a design that reduces the weight of the component and improves its strength for the 2024 racing season. | This episode of The Cool Parts Show is sponsored by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- More on IndyCar’s 3D printed top frame

- A specialized heat exchanger for an electrified student race car

- 3D printed parts used in off-road racing

- How Alfa Romeo Sauber uses additive manufacturing in the development of its Formula 1 cars

Transcript

00:00:00:00 - 00:00:00:19

Pete Zelinski

I'm Pete.

00:00:00:19 - 00:00:06:01

Stephanie Hendrixson

I'm Stephanie. And this is The Cool Parts Show our show all about interesting, unusual 3D printed parts.

00:00:06:01

Pete Zelinski

We're not in our normal studio. We are in Indiana, just minutes away from the Indianapolis Motor Speedway.

00:00:12:02 - 00:00:19:22

Stephanie Hendrixson

We're here to talk about this top frame. This is a part used in Indy car racing that is now so important that it is mandated on all of the cars,

00:00:19:22

Pete Zelinski

The 3D printed topframe. We're going to find out why it's so important to IndyCar race cars, why it had to be made through additive manufacturing. On this episode of the Cool Parts Show.

00:00:55:15 - 00:00:58:00

Stephanie Hendrixson

Welcome to The Cool Parts Show on location.

00:00:58:00 - 00:01:07:00

Pete Zelinski

Thank you for watching. If you like the show, please subscribe. We have a new newsletter, The Cool Parts Show All Access with extra segments just for subscribers.

00:01:07:00

Stephanie Hendrixson

Today we're bringing you a part from the world of IndyCar racing. This 3D printed top frame is a safety component that's used in these cars. But first, we're coming to you from the Dallara IndyCar factory. Dallara is an Italian engineering and manufacturing company. They're headquartered in Italy, but they have this second location here near Indianapolis. Right now, we're actually in Speedway, Indiana. We're about a mile away from the Indianapolis Motor Speedway.

00:01:30:13

Pete Zelinski

Dallara builds and assembles race cars. Race cars for the IndyCar series.

And an IndyCar racer obviously has a lot of components. Some components are installed by the individual race teams. But we're going to talk about a part that is a standard component of every single car in that series.

00:01:50:15

Stephanie Hendrixson

That's right. This time frame is a newer addition to the Indy car. It was mandated as of the 2020 season and it sits sort of in front of and above the driver's head to protect him or her in a couple of different ways. It's primary purpose is to hold the aero screen, which is a strong windshield that protects the driver from any debris that might be coming up off the track, coming off of other cars. And then it also acts as a sort of a roll cage in case of an accident.

00:02:17:15

Pete Zelinski

So this is a very important component of the car. The top frame is this entire piece you see here, except for these thin little assembly brackets that have been added on. It's titanium. It was made through additive manufacture initially because of the very fast development time for this part. Tight time frame from initial conception through to final production. But as we're going to hear, because this was made through 3D printing, there were opportunities to refine the design later, after it had gone into production, to the point that the latest iteration of this component is a superior part to what was initially introduced. But first IndyCar. This is a special racing series with a particular connection to manufacturing.

00:03:06:19

Stephanie Hendrixson

That's right. You may have seen other 3D printed parts for racing, but most of the examples that have been publicized that are out there are things that the teams have developed and created themselves. So they might just be making maybe one or two for use on the car for a season. In IndyCar racing, the cars are much more standardized than in some of the other series. And so there are components like, for instance, this top frame that get made in higher quantities because they're going to be used by every team on every car.

00:03:32:13 - 00:03:46:13

Pete Zelinski

That's what makes Indy Car distinctive. This connection that it has to production. And to talk about that, here's Tino Belli. He is director of Aerodynamic development for IndyCar.

00:03:46:13

Tino Belli

IndyCar is the sanctioning body of the NTT IndyCar World Racing Series. It's a 17 race series. The most famous race is, of course, the Indianapolis 500. So IndyCar is an open wheel racing series. We race on road and straight tracks. What really distinguishes us from any other racing series is that we then also race on ovals. So we race on short ovals like Milwaukee and Iowa, which are one mile or less. And we also race on the super speedways like Indianapolis, which is two and a half miles, very, very high speed and an average speed of 230 miles an hour or more. We're quite strong on keeping a lot of the car standard because the economics. At the end of the day, racing is a competitive series, but it's also an entertainment business. Part of the quality of entertainment is car count. We have to try and keep the number of cars up so that people are always seeing action on the track. And we don't want anybody running away and winning every race. So if we keep the cars fairly close together, it comes down to quality of the drivers, quality of the teams in their pit stops and how they set up the car, rather than making a huge technological advance which nobody else can keep up with if they can't afford to keep up with it. We encourage the little guys to be able to have a chance at winning some races.

00:05:20:13

Stephanie Hendrixson

So this is a really big deal. Prior to 2020, the drivers wore helmets, but they didn't have anything on the front of the car to do exactly what this top frame does. And drivers have been seriously injured. You can think of all the things that might go wrong when you're out on the track. So the addition of the top frame and the aero screen that it supports was a big jump forward in terms of driver safety and other series have sort of dealt with a similar problem in similar ways. Like you might have seen the Formula One Halo. IndyCar decided to take a little bit of a different approach.

00:05:52:04

Tino Belli

As you can imagine at the Indy 500, where you're traveling over a 230 mile an hour the aerodynamics of the top frame and the windscreen is quite important. So let's compare our top frame with the halo. The halo is basically a bent tube around the driver's head. Our shapes are more elliptical, more airfoil type shapes. So the top frame is quite, quite a complex and challenging

part to manufacture.

00:06:24:12 - 00:06:33:00

Pete Zelinski

IndyCar recognized it was a big deal once they saw the need for this component and they moved quickly on getting it developed.

00:06:33:00

Tino Belli

The top frame aeroscreen project was very, very short gestation. It started in May of 2019 and we had it on track here in Indianapolis in October 2019. We contracted Red Bull Advanced Technologies to be the main design contractor for the top frame. The aeroscreen and the composite structure that had to be added to the monocoque for the top frame.Our other partners of course, is Dallara, who is our main manufacturer of the race car.They really did the aerodynamic work, the CFD and the wind tunnel work to make sure that the top frame and aeroscreen integrated well into the car. And then finally we contracted with Aerodyne which is a composite company here in Indianapolis, who actually did the composite lower frame, which bonds to the cockpit opening which the top frame and the aeroscreen attach to.

00:07:36:15 - 00:07:50:23

Stephanie Hendrixson

So aerodynamics and strength were major concerns in the development of this top frame, but it also had to integrate into the car design that already exists. Here to talk about that is Dominic Coffey. He is a design engineer and project manager here at Dallara USA.

00:07:52:18 - 00:08:04:11

Dominic Coffey

So the design of the top frame is driven by the architecture of the monocoque that it sits on. So a lot of the end conditions were driven by the size of the cockpit that the driver sits in. So we had to maintain that envelope for the driver to ingress and egress from the car. So that kind of drove the top conditions of the frame, the front conditions of the frame and the windscreen were driven by the suspension that the car already had. So it's very close to the spring and damper setup of the front suspension. So that drove how far the frame and screen could go forward.

00:08:31:18

Stephanie Hendrixson

So all of this back and forth ultimately led to this kind of wishbone design that can hold the aero screen, doesn't interfere with anything else on the car, and it's still wide enough that you can get the driver out in case of an emergency. But when it came time to actually manufacture this thing, there were a whole new set of challenges to contend with.

00:08:50:10

Tino Belli

Three methods of manufacturing were considered like straight fabrication, casting and 3D printing. 3D printing really came through because we could get the shapes and the wall thicknesses and everything that we wanted more easily than casting and fabrication just plain wasn't going to work right from the beginning.

00:09:14:01 - 00:09:27:15

Stephanie Hendrixson

So these top frames are 3D printed and assembled in Austria at a company called Pankl, which is a supplier to the automotive and motorsports industries. Here is Stefan Seidel, the CTO of Pankl Racing Systems.

00:09:27:15 - 00:09:48:12

Stefan Seidel

10 years ago, Pankl Racing System decided to introduce additive manufacturing to our already vast machining portfolio. It enabled us to create designs and products that had not been possible before, and hence it's a very interesting addition and enables us to push the limits wherever we can.

00:09:48:12 - 00:10:09:11

Stefan Seidel

The time frame for this whole project, Initially, it was very tight. Therefore, we had to look at design and production methodologies that enabled us to have the first prototypes on the car very, very fast. 3D printing is the ideal production method for this, and that's why it was for us the only choice to go this route.

00:10:09:11 - 00:10:13:13

Pete Zelinski

The 3D printing method is laser powder bed fusion.

00:10:13:14 - 00:10:18:04

Pete Zelinski

The top frames are produced on an additive manufacturing machine from EOS,

00:10:18:04 - 00:10:47:07

Pete Zelinski

This top frame is way larger than the build chamber of that machine. To enable one build cycle to produce one top frame, the part is split into five different pieces that can nest together into a more compact build. It’s welded together afterwards to produce the solid part. Pankl manufactured one top frame per IndyCar this way actually manufactured more than that.

00:10:47:07 - 00:10:57:21

Tino Belli

The original top frame, we produced 66 of them and the reason we produce 66 is we have 33 cars at the Indianapolis 500.

00:10:57:21 - 00:11:04:03

Tino Belli

So we needed one for each car. And every car has a spare, so we just doubled it to 66

00:11:04:03 - 00:11:12:21

Pete Zelinski

And those 66 top frames come here to Dallara. This is where assembly happens. Here's Dominic again to talk about

00:11:12:21 - 00:11:15:19

Pete Zelinski

what happens once the top frames arrive.

00:11:15:19 - 00:11:28:23

Dominic Coffey

When we get the top frame from Pankl it's an uncoated condition. So we sand it down, we paint it, and then we install some composite, what we call Z-brackets on the frame that the windscreen attaches to.

00:11:28:23 - 00:11:45:09

Dominic Coffey

So the top frame is fastened to the monocoque with 14 fasteners. There are six at the front leg of the top frame just in front of the driver. Therefore immediately next to the driver's head, two on each side. And then there are four back to the monocoque roll hoop.

00:11:45:09 - 00:11:49:07

Dominic Coffey

So IndyCar has been running the same monocoque since 2012.

00:11:49:07 - 00:12:05:19

Dominic Coffey

At the time we were wanting to retrofit the tubs that the teams had. So there was a lot of work going into optimizing it to fit was already there, which led into a lot of work being done with working with the tolerances of the monocoque.

00:12:05:19 - 00:12:06:20

Pete Zelinski

So this part has

00:12:06:20 - 00:12:11:00

Pete Zelinski

been a success, not just on the track, but even before it got to the track.

00:12:11:00 - 00:12:13:23

Pete Zelinski

In Indy Cars testing.

00:12:13:23 - 00:12:26:10

Tino Belli

We load tested the top frames. Obviously the the top frame is designed with FEA analysis and then we made a fixture at Cranfield Impact Centre in

00:12:26:10 - 00:12:36:15

Tino Belli

the UK and we loaded up the top frame to 150 killer neutons, which is about six Chevy Silverado trucks

00:12:36:15 - 00:12:45:03

Tino Belli

None of the top frames actually failed up to that load, so they also didn't take permanent

00:12:45:03 - 00:12:50:18

Tino Belli

defamation. So those top frames have actually been on race cars for the last three years as well.

00:12:50:18 - 00:13:01:09

Tino Belli

The only time we damaged a top frame is when a car gets upside down, inverted on the track and the titanium rubbed away on the asphalt.

00:13:01:09 - 00:13:08:20

Tino Belli

A great advantage to it has been that previously if that had happened, we would have rubbed the way

00:13:08:20 - 00:13:15:19

Tino Belli

through the carbon fiber of the monocoque cockpit opening and that's irreparable.

00:13:15:21 - 00:13:35:01

Tino Belli

So all of the monocoque’s that have been in accidents like this have actually stayed in commission and continue to race, whereas in the past they would have been scrapped. So in the long run the top frame has saved us or saved the teams a significant amount of money.

00:13:35:01 - 00:13:54:12

Pete Zelinski

So the top frame has been very successful, but the manufacturing partners involved with this part recognized it could be made better. So back to 3D printing, back to additive manufacturing as the means of producing this part. We heard Stefan describe why additive was chosen initially.

00:13:54:12 - 00:14:27:09

Pete Zelinski

It's because of the fast development time for this part. The idea was conceived in May and it was on race cars on the track in October. It went that fast. It got into production that fast. But once it was in production and once it was proven on the cars, there was the opportunity at that point because it was made through 3D printing to step back and bring in some of the other advantages that additive manufacturing can bring to the possibilities for a part like this.

00:14:27:09 - 00:14:40:23

Stefan Seidel

With all of our experience on the design, on the simulation, on the material, as well as on the production side of the top frame, we decided to have another go and to optimize the first frame as far as possible.

00:14:40:23 - 00:14:43:03

Stefan Seidel

In the second generation,

00:14:43:05 - 00:15:02:14

Stefan Seidel

Our goal was to further optimize the design and to reduce the weight and offer also a commercial benefit, because in additive manufacturing, reduced volume, reduced weight also means reduced cost because there is less volume to be printed, less material used.

00:15:02:14 - 00:15:09:12

Stefan Seidel

So we could offer the IndyCar and all its customers an optimized version at reduced cost.

00:15:09:12 - 00:15:29:16

Stefan Seidel

We used topology optimization as well as several simulation tools in additive manufacturing to really get the optimum out of both worlds because you always need to consider material, process, and design in order to get the optimal out of the performance.

00:15:29:16 - 00:15:37:09

Stephanie Hendrixson

So Pankl, Dallara, IndyCar have been working on the second generation of these top frames, which have been further optimized.

00:15:37:09 - 00:15:54:02

Stephanie Hendrixson

They're going to be about 7 pounds lighter and they're going to be going onto the cars as of the 2024 season. That's important because it also coincides with a new change in racing. The IndyCars are going to a hybrid engine and so there have been a lot of efforts to remove weight out of the car overall,

00:15:54:02 - 00:15:57:00

Stephanie Hendrixson

the redesigned top frame is going to contribute to that.

00:15:57:00 - 00:15:58:18

Pete Zelinski

All right, let's wrap this up.

00:15:58:20 - 00:16:24:10

Pete Zelinski

This is an IndyCar top frame, relatively new component of IndyCar race cars. It protects the driver. It protects in the event of a rollover. It protects against objects that might be flying toward the car on the course. It was made through additive manufacturing initially because this component was developed quickly, brought into production quickly. It's made through laser powder bed fusion.

00:16:24:10 - 00:16:40:10

Stephanie Hendrixson

This top frame is titanium. It is 3D printed in five pieces, which are then welded together, machined painted before being assembled onto the cars here at Dallara, USA. The first generation of this top frame was pretty lightweight already, but the second generation is coming for the 2024 season

00:16:40:10 - 00:16:46:04

Stephanie Hendrixson

that's 7 pounds lighter. It's going to help reduce the weight of the car, which is really important as these cars switch over

00:16:46:04 - 00:16:47:13

Stephanie Hendrixson

to hybrid engines.

00:16:47:13 - 00:16:52:11

Pete Zelinski

I want to say thank you to Pankl and IndyCar for sharing this story with us.

00:16:52:11 - 00:16:55:21

Pete Zelinski

Big thanks to Dallara for letting us film in their facility.

00:16:56:02 - 00:16:59:22

Stephanie Hendrixson

Yes. A big thank you to everyone who helped us out for this episode.

00:16:59:22 - 00:17:09:18

Stephanie Hendrixson

If you like the show, you want to see more of The Cool Parts Show. Find all of our episodes at TheCoolPartsShow.com and on our YouTube channel. And if you really like the show, sign up for our All Access newsletter.

00:17:09:18 - 00:17:21:13

Stephanie Hendrixson

This month, subscribers got to see an exclusive extra about one of the other 3D printed components that are going to be used on any cars soon. So you can see that too. And sign up at TheCoolPartsShow.com/AllAccess.

00:17:21:13 - 00:17:25:04

Pete Zelinski

If you have a story of a cool part, you want to share with us

00:17:25:04 - 00:17:32:20

Pete Zelinski

the way IndyCar shared the story of this top frame, email us CoolParts@AdditiveManufacturing.media. It might become an episode of the show.

00:17:32:20 - 00:17:34:20

Stephanie Hendrixson

Thanks for watching.

00:17:34:20 - 00:17:37:06

Pete & Stephanie

episode is brought to you by Carpenter Additive.

00:17:37:06 - 00:17:56:14

Pete & Stephanie

We are at the company's power production facility in Athens, Alabama, and we are standing on top of an atomizer. The Z one is Carpenter technology's largest vacuum atomizer and it has been part of the process for making additive manufacture wring metal powder here in Carpenter Avenue.

00:17:56:14 - 00:18:02:02

Pete & Stephanie

This facility is capable of producing up to £18,000 of metal powder per day.

00:18:02:04 - 00:18:05:14

Pete & Stephanie

Plant manager Jordan Ralph talked this through the process

00:18:05:14 - 00:18:14:21

Jordan Ralph

an atomizer is a piece of equipment that is capable of melting and pouring molten metal into the stream of

00:18:14:21 - 00:18:25:17

Jordan Ralph

high pressure gas that turns that molten metal into tiny, tiny droplets that ultimately cool and form our powder, which looks like a great dust.

00:18:25:17 - 00:18:35:23

Jordan Ralph

so to start our process and the ultimate in the end solution that we have here, we bring in raw materials all the way down to individual elements.

00:18:35:23 - 00:18:43:11

Jordan Ralph

So nickel, cobalt, chrome, mali, niobium, we bring all of those raw materials into the shop

00:18:43:11 - 00:19:07:04

Jordan Ralph

we utilize those materials to build the charges that go into the atomizer. as you walk that flow path, we run through our charge make up area where all of the materials are laid out very exact quantities that ensures that we're able to hit our customer specifications and hold the tight tolerances that we're looking for.

00:19:07:04 - 00:19:12:09

Jordan Ralph

On a chemistry perspective from there, the material is flown to the

00:19:12:09 - 00:19:15:07

Jordan Ralph

top of the atomizer and charged into the furnace

00:19:15:07 - 00:19:20:08

Jordan Ralph

as the materials produced, and it's poured out and is collected at the bottom of the atomizer.

00:19:20:08 - 00:19:25:03

Jordan Ralph

The material is then taken and transferred into

00:19:25:03 - 00:19:25:14

Jordan Ralph

a

00:19:25:14 - 00:19:30:19

Jordan Ralph

bulk container, for processing through the rest of the value stream.

00:19:30:23 - 00:19:55:14

Jordan Ralph

the next stop for any of our as atomized powder would be the screener. So that will remove the coarse portion of the powder. From there, we take it through air classification. It takes the fine portion of the particle size distribution out and makes the final cut for an additive material like a 10 to 45.

00:19:55:14 - 00:20:04:06

Jordan Ralph

From there we stack up all of those individual lots and put them into the £12,000 blender to make the single homogenous blends.

00:20:04:08 - 00:20:06:20

Jordan Ralph

At that point we are able to pack in

00:20:06:20 - 00:20:13:02

Jordan Ralph

any configurations the customer is looking for, whether that be drums, bottles, powder, trace hoppers.

00:20:13:02 - 00:20:16:19

Jordan Ralph

Really we've got a lot of a lot of options to meet customers needs there.

00:20:16:19 - 00:20:44:01

Jordan Ralph

the atomization capability and all of the powder capabilities gives us a unique, you know, position where we're actually able to produce the powder run testing through additive machines all the way through hip and heat treat, do final testing on those products and then make additional changes or try to optimize, you know, things like our chemistry or sizing

00:20:44:01 - 00:20:48:08

Jordan Ralph

so that we ultimately can serve our customers better.

Related Content

Video: How Multimaterial Laser Powder Bed Fusion Works

Penn State University’s CIMP-3D is exploring applications of the Schaeffler Aerosint system for multimaterial 3D printing. During a recent visit, I got an introduction to this system.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreQuadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

How to Accelerate Industrial Additive Manufacturing

The 2018 Additive World Conference was dedicated to industrial additive manufacturing and covered all relevant topics from the fields of 3D design, simulation, manufacturing and materials as well as case studies.

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More

.jpg;width=70;height=70;mode=crop)