Hear Proto Labs’ Recorded Webinar on Choosing Among Plastic 3D Printing Options

SLS, stereolithography or polyjet? The answer depends. Each process has its strengths.

Which is the right polymer 3D printing process out of selective laser sintering (SLS), stereolithography and polyjet? The answer, of course, depends on the application. All three of these processes have their strengths, and all three pose different challenges.

Eric Utley discussed these three processes in a recent webinar. Utley is an application engineer with Proto Labs, which offers 3D printing services employing any of these options.

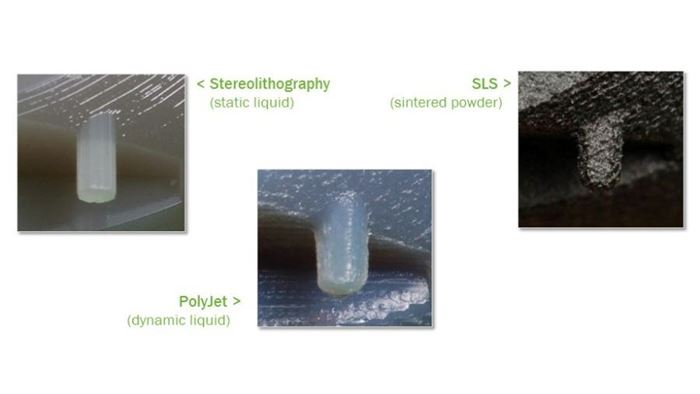

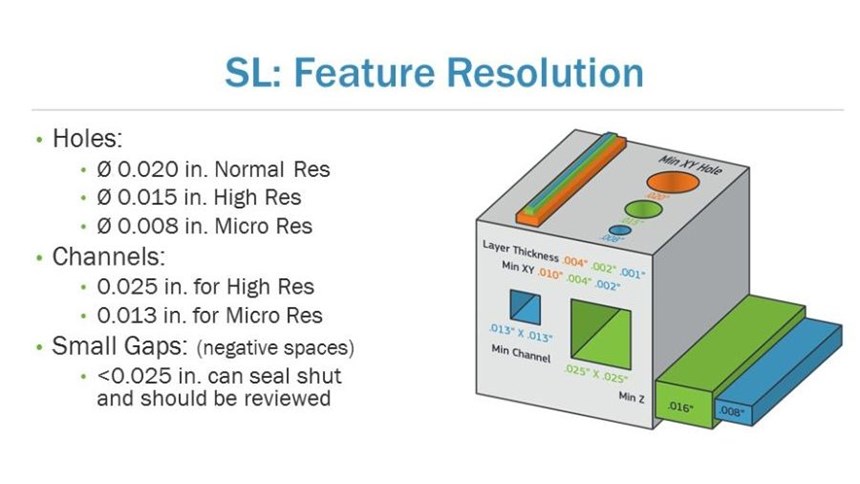

SLS, which prints in nylon, “produces some of the most durable plastic parts you’re going to get with 3D printing,” he says. Yet the surface finish, in his words, resembles unfinished drywall. Stereolithography, by contrast, permits fine resolution for smooth surfaces and crisp feature detail. But even here, there are nuances. Stereolithography’s precision is affected by its minimum build layer size in the Z direction (0.016 inch on some systems). The part should therefore be oriented so that fine feature details are formed in the X-Y plane.

From the presentation, here are Utley’s summaries of where the three processes make sense:

Why Use SLS?

The durable choice among these three options is particularly useful for....

- Reduction of components and quicker assembly times through consolidating assemblies

- Reduction of part weight through redesign for 3D printing

- Durable prototypes

- Making living hinges and other movable parts

Why Use Stereolithography?

This choice is 3D printing is valuable because it provides....

- A wide selection of material

- Fine feature resolution

- Smooth surface finishes

- An effective option for very small parts

Why Use Polyjet?

Jetting material through a mechanism not unlike a document printer, polyjet allows for the creation of parts that feature....

- Grip and impact resistance

- Soft touch

- Two-toned coloring

- Intricate detail and delicate features

While polyjet also allows for the creation of....

- Prototypes that simulate elastomers or flexible parts

- Prototypes of overmolded parts

- Gaskets and seals

- Multi-material components

In the webinar, he expands on these basic points to cover the limitations and considerations of each process. Topics covered include material choices, design considerations, support structures, and build orientation. Watch and listen to the recorded presentation.

Related Content

-

FDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

-

6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.