GF Machining Solutions Thinks Additive and Beyond

At the GF Machining Solutions 2019 Solution Days event, the company showcased two technologies that make clear its intention to move additive manufacturing into production.

At an event like GF Machining Solutions’ 2019 “Solution Days,” perhaps it’s not surprising for a writer/editor like me who often focuses on additive manufacturing to immediately be drawn to new 3D printing and postprocessing technologies. But it’s also fair to say that — for a company often associated with milling, wire EDM and laser micromachining — these technologies stood out on their own right.

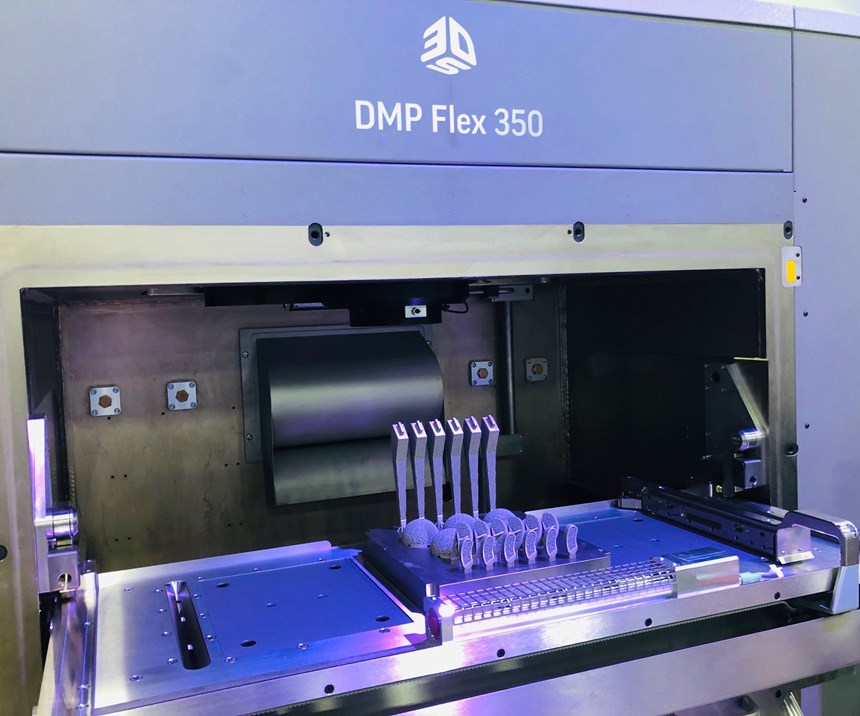

Front and center were the DMP Flex and DMP Factory 3D printers, respectively single- and triple-laser metal powder-bed fusion machines that resulted from GF Machining Solutions’ partnership with 3D Systems announced at IMTS last year. Each model number, 350 and 500 respectively, represents (roughly) the build volume in millimeters across the X, Y and Z axes. Both models are modular machines with optional integrated powder management systems for steel, Inconel and other nickel alloys, titanium, and other metals. On display at the event was only the DMP Flex machine, which still carries 3D Systems’ branding, although I was told that will change in the future.

The company highlighted the build chamber atmosphere’s purity (oxygen levels are said to be less than 25 parts per million) as being key to high repeatability, microstructure uniformity and accuracy, but equally interesting was the bidirectional material deposition resulting from new technologies incorporated into the recoater blade. For those who have upgraded the powder management system, it was said that printer cartridge changeover time is less than 30 minutes. John Carlson, GF Machining product manager, said that the DMP Factory systems “are meant to get into true production — especially when you think about our postprocessing capabilities.”

Which brings us to a unique — or at least unique to me — twist on cutting parts from the build plate via wire EDM. The not-officially-released AgieCharmilles Cut AM 500 is a horizontal wire EDM system designed specifically for additively manufactured part cut-offs. The machine, which GF Machining will debut at EMO Hannover later this year (no photos allowed until then), features an integrated swivel axis that rotates the build plate 180 degrees, submerging the parts upside-down into a special, water-based dielectric solution (the solution was said to be more viscous than typical EDM solutions). This orientation allows the parts to be cut without pressure or risk of damage via collision that can occur when being cut vertically, and also reduces the amount of supporting material that needs to be printed between the build plate and part itself. Gravity ensures that the parts won’t pinch the wire during cutting operations, which runs the risk of short-circuiting or breaking the wire. After being cut from the platform, the parts simply fall through the fluid into a basket inside the machine. The basket itself can be shelved or segmented to catch individual parts.

An available upgrade to the Cut AM 500 is a clamping and referencing option to speed up the removal of cut parts while queueing up the next build plate for part removal. Inside the machine, which features an X, Y and Z-axis travel space of 19.69 × 19.68 × 19.68 inches, are two wire spools that allow for the use of reusable Moly wire.

As additive manufacturing moves swiftly toward higher production volume capabilities, GF Machining Solutions’ back-to-back release of new printing and postprocessing machine technologies feels logical and necessary for anyone looking toward holistic AM solutions.

Related Content

AM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More