AM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Share

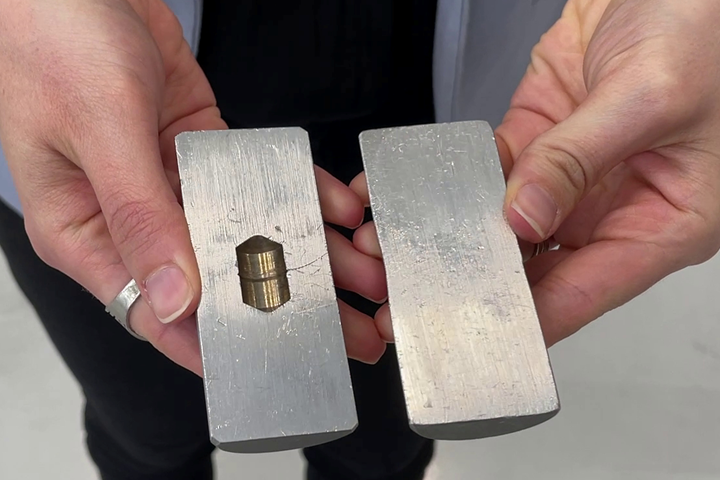

A dramatic illustration of the capabilities of HIPing. While the process is often used to mitigate porosity throughout a part, it can also be applied to close a much larger void like this one. More in the video below. JUMP TO VIDEO

What is hot isostatic pressing (HIP)?

Hot isostatic pressing (also called HIP or HIPing) is a process that consolidates material and closes pores within parts through the application of heat and pressure. It can be applied to many different materials including metals and ceramics. Like furnaces used for more general heat treating of metal parts, HIP furnaces relieve thermal stresses in cast, sintered and additively manufactured parts. However, HIP can also improve part density, ductility, fatigue resistance and other material properties. The HIP process can also include quenching, aging and other postprocessing steps.

How does HIPing work?

The HIP process takes place in a pressure vessel inside a high-temperature furnace. Parts are loaded into the chamber which is then heated, pressurized with an inert gas such as argon, and held at this temperature and pressure for a specified amount of time. The heat and pressure are applied evenly to the part (isotropically), forcing out porosity. The HIPing process can also include pressurized rapid cooling, which functions as a quenching step. HIP cycles can take 8 to 12 hours or longer.

What is the process for hot isostatic pressing of 3D printed parts?

HIPing is now being used for postprocessing of metal 3D printed parts, typically those produced by powder bed-based processes like laser powder bed fusion (LPBF) and binder jetting, though directed energy deposition (DED) parts are sometimes processed this way as well.

Printed parts — either cut off or still on their build plates — are loaded into baskets and transferred to the HIP furnace’s chamber. The chamber is filled with inert gas, heated and pressurized, then held at temperature and pressure for a specified length of time. HIPing “recipes” are customized to the particular material and desired final properties.

Parts needing HIPing are staged in metal baskets (far right) before being loaded into a pressure vessel and into the HIP furnace (left).

Why HIP 3D printed parts?

Powder-based metal 3D printed parts can suffer from issues like poor layer adhesion, porosity and other defects; HIP offers a way to mitigate these issues by consolidating the material and potentially reducing the severity of any remaining defects. HIPing creates a uniform microstructure in the material, which can improve properties.

Hot isostatic pressing also offers consolidation of steps in the manufacturing process. Many metal 3D printed parts require heat treat after printing to relieve residual thermal stresses; the HIP furnace can accomplish this heat treat alongside quenching, aging and other beneficial processes, saving time in the overall production of metal parts.

Related Content

BPMI Chooses Velo3D Metal 3D Printing System to Produce Parts for U.S. Naval Nuclear Propulsion Program

The fully integrated 3D printing solution will be operated by ATI in a newly established facility that will provide the U.S. Naval Nuclear Propulsion Program with alternatives to cast parts.

Read MoreEOS Works With Phillips Federal, Austal USA to Develop CopperAlloy CuNi30 for US Navy Submarine Industrial Base

Using the copper-nickel alloy in combination with EOS’ platforms offers new design and production capabilities for U.S. Navy submarines, while also enabling the agency to limit global supply chain disruption because parts can be produced regionally, locally and on-demand.

Read MoreAdditive Enhances Lost Foam Casting Process for Metal Manufacturing

Skuld LLC brings a new, 3D printing-enabled version of lost foam casting to market via its turnkey package for metal manufacturers. Additive Manufacturing Evaporative Casting (AMEC) enables metal parts made with sustainability and efficiency in mind.

Read MoreEaton Evaluates Foundry Lab Process as Die Cast Alternative: Aids Prototyping and Supply Chain

Foundry Lab’s digital casting is an additive-enabled process that delivers cast parts. Eaton AM manager describes how near to die casting the process comes, and what promise he sees.

Read MoreRead Next

Why Does My 3D-Printed Part Cost So Much?

The machine, the facility and the material are just three costs behind the price tag.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More.jpg;width=70;height=70;mode=crop)