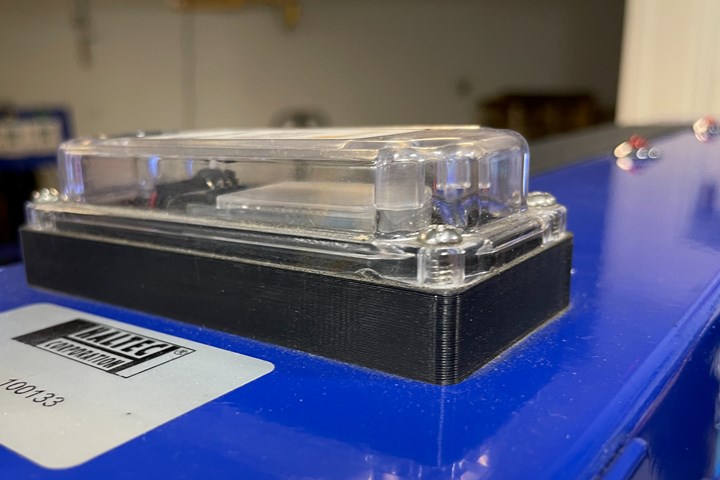

Haltec Corporation has diversified its business in the last decade to offer tire-related technologies other than valves. Inflation systems like this are customized to the client’s needs, with any number of different sensors and other electronics inside.

Vehicles of all types are becoming "smarter" in terms of sensors, warning systems and corrective assistance features. But the technology for servicing the tires of these vehicles is advancing almost as quickly — bringing increasingly shorter product development cycles for these support systems.

Haltec’s specialty is tire valves for large, heavy duty equipment (think: agricultural tractors, mining equipment and construction vehicles) which it turns mostly from brass at its Leetonia, Ohio, manufacturing campus.

“Many of our big customers have the resources to do what we do, but they use us because we’re faster,” says Adam Kemp, vice president of engineering at tire equipment manufacturer Haltec Corp.

Headquartered in Leetonia, Ohio, the company has provided valves for heavy equipment tires for more than 40 years. More recently, Haltec Corporation has begun to expand its operations into various systems around those tires, including specialized units for measuring, inflating and maintaining them. This work is where the speed matters, and where 3D printing is making a difference in how it can serve those customers.

Alongside its tire valve products, Haltec Corporation also produces inflation systems used at Love’s truck stops, Discount Tire stores and similar businesses. Rather than simple air compressors, these inflation systems can be highly complex and intelligent, and are often equipped to identify vehicles and capture data about their tire condition. The products are used in heavy industry to maintain fleets of equipment; by shipping companies to monitor the condition of their trucks; and at tire stores to let regular drivers quickly reinflate and access information about their cars.

Besides the necessary inflation equipment, each of these systems also can contain any number of sensors, communication devices or other features that the customer desires. Increasingly, the company is using its 3D printers to prototype and sometimes produce the custom brackets and other components these products need.

From “Paper Dolls” to Printed Parts

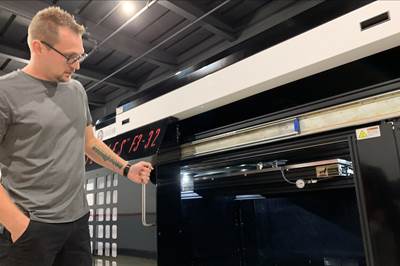

3D printing at Haltec Corporation has a short but effective history. The company added its first desktop 3D printer, a PowerSpec Ultra 2.0 purchased at Microcenter, in 2019. Two identical machines followed soon after. The 3D printers offer dual extruders and are enclosed; they are suitable for printing up to 245°C, which accommodates the ABS material that Haltec mostly uses. Two of the printers are running nearly 24/7, while the third is always left open to handle unplanned work that might come up.

Product development engineer Adam Shields stands in front of the company’s FFF 3D printers. Two of these machines are running near constantly to make prototypes, shopfloor tooling and production parts. The third is left available for other jobs, like employee of the month plaques and more experimental parts.

This 3D printing capacity was added initially for speeding product development and creating more functional prototypes. When developing a new inflation system, the company’s requirements are to deliver the features requested by the customer within a cabinet size and shape they designate.

“Everything is based on a LEGO concept,” Kemp says. “We make configurable products, and then let customers configure them.”

3D printing has also found its way onto the machine shop floor, in the form of check gages, jigs and other fixturing. Adam Kemp holds a 3D printed drill guide that holds the round handle of an inflation system in place so that holes can be drilled through.

But fitting all the necessary hardware inside of a new cabinet size or configuration does require some amount of tinkering. In the past, the R&D team’s go-to method for working out the internal layout of an inflation system involved what they call “paper dolls” — literally, pieces of paper and cardboard cut to represent different brackets, instruments and components.

With 3D printing, the team is now able to create prototype parts that are much better representations of the final products, both from a geometry and functionality standpoint. The printed parts are strong enough to enable the use of real fasteners, instruments, cabling and other internal components earlier in the product development phase, making the overall process faster for each new inflation system.

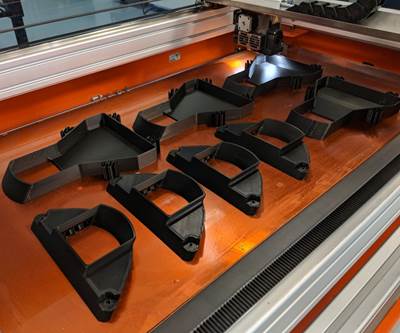

Some of the printed items have even found their way into production. Examples include a bracket that protects a printed circuit board (PCB) inside a system offering three different tire inflation setting options.

For another inflation system, Haltec Corporation 3D prints a “stand off,” a riser that separates the Bluetooth communications from the metal cabinet, which previously was causing the device to lose its signal when the technician moved to inflate tires on the other side of the vehicle.

This black ABS 3D printed “stand off” provides just enough separation from the metal cabinet to keep the inflation system’s Bluetooth communications working.

Prior to 3D printing, parts like this would have been machined metal or injection molded plastic — processes that the company still uses for many components. But now, according to Justin Gloeckner, director of research and development, 3D printing is becoming a preferable manufacturing (as well as prototyping) option.

“It costs about 30 cents to print one ABS bracket, and we produce about 10 per week,” he says. “The part price through injection molding would be lower, but we would face minimum order quantities in the thousands. At these volumes, 3D printing just makes sense.”

Judged by the Cover

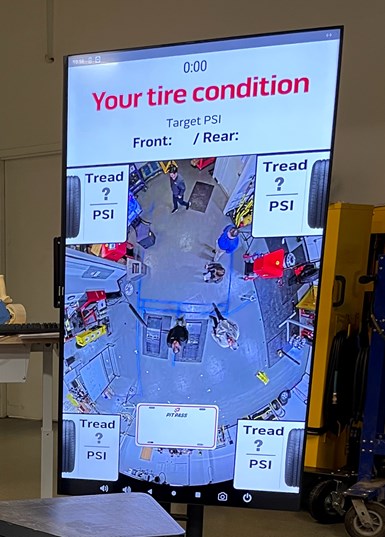

But before a new inflation system goes into production, it has to pass the ultimate test: feedback from the customer. The company’s research and development lab is constantly being rearranged, Kemp says, because this is the site where clients come to see how their systems will work in use. When I visited, a demo of a new system for Discount Tire was set up in the lab, including a drive-over sensor that measures tire tread depth as a car passes over it, and inflation cabinets for handling both the driver and passenger sides of the vehicle.

These particular cabinets represent a 3D printing success of a different kind. In production units, outer structures like this are formed from sheet metal and are typically prototyped through that same manufacturing method. But forming requires tooling and tooling takes time; in this case, Haltec Corporation did not have 6 weeks to wait for a steel prototype.

In production, tire inflation cabinets are made from formed sheet metal (left). But in developing this system for Discount Tire, Haltec Corporation instead turned to 3D printed cabinets made by Juggerbot. The first iteration (right) was too tall once installed on the stand. The R&D team adjusted the design for the next print, then sanded and painted the resulting cabinet before building it out as a working prototype (center, on stand).

This screen provides an overhead view of the R&D lab, where clients come to see products tested before going into production. The complete Discount Tire system includes two of the red inflation cabinets (one for each side of the vehicle) and a drive-over sensor for checking tread depth (center; Adam Kemp in black stands near it).

Instead, the company teamed up with Youngstown-area company Juggerbot to iterate the cabinet on the latter’s Tradesman platform. The large-format 3D printer can print a variety of thermoplastics using pellet or filament feedstocks. The team went through two iterations of the cabinet design in two weeks, tweaking the look as well as usability.

“In the first design the cabinet was too tall,” recalls Adam Shields, product development engineer. “When we had the printed version on the stand we could visualize how a user would interact with it, and see that the height needed to change.”

The prototype cabinet that was built out as a working inflation system was 3D printed from glass-filled nylon, then sanded and painted to match the client’s corporate colors. The demonstration was a success — the customer was even surprised to learn that the cabinet was 3D printed.

Exterior cabinets like this that must be watertight and stand up to the elements outside probably won’t be 3D printed for production any time soon, Kemp says. But the company does anticipate turning to 3D printing more often to prototype these components, both for the look-and-feel experience they provide and the cost savings.

“We can get to these designs better, faster and quicker without spending a ton of money in tooling,” Kemp says. The system is now in production (with a formed metal cabinet based on this prototype) and at least one is already in operation at a Discount Tire store.

Fast, Flexible, Agile

Successes thus far with 3D printed prototypes, tools and production parts are driving Haltec Corporation to expand the use of this technology. The company plans to add FFF 3D printers in the future that can maintain higher heat limits for the sake of printing with higher-strength materials, which will open the door to more production parts made this way.

The company also sees many opportunities for 3D printed elastomeric materials as alternatives to molded rubber components like grommets and other air-sealing surfaces. These might be materials applied through FFF or SLA technology, maybe added in house. (The engineering team already uses SLA services to produce some smaller components and even prototype valves.)

Newer 3D printable elastomers available in durometers similar to conventional rubber are making it possible for the company to explore prototyping and manufacturing parts like this O-ring via 3D printing.

Whether printed parts go into production or remain in the prototype stage, implementing additive has helped Haltec Corporation with its mission to be a “fast, flexible and agile” partner for these inflation systems, Kemp says. Although many of its larger customers in theory have the resources to do this type of development themselves, they continue to turn to Haltec for its configurable platform and ability to quickly iterate systems until they are just right — enabled in part by 3D printing.

Related Content

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read More3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read More8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

Read MoreRead Next

How a Prototyping 3D Printer Became a Production 3D Printer

Boyce Technologies was already a leader in manufacturing communications devices, but 3D printing and a partnership with BigRep have helped it remain competitive—first through prototyping, and now in production.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read More3D Printing at the Turn of Iten’s Century

This specialist in laminates, composites and plastics manufacturing will turn 100 years old in 2022. 3D printing in polymer will be part of the company’s next hundred years, leadership says.

Read More

.jpg;width=70;height=70;mode=crop)