AM’s Advance into Production Reveals How Some of the Misperceptions Were Partly True

Is additive manufacturing efficient for producing current part designs? No … except also yes. Is it a replacement for current processes? No … except when it is. Recent posts reveal the role additive is likely to play in production.

When I recently visited Spirit AeroSystems, my hosts took me to the production area for Boeing 787 fuselages, so I could see the installation of the first titanium structural component for this plane to be made through additive manufacturing (AM). Even though the part is an important milestone, I wasn’t expecting a dramatic experience. I guessed the technician would install the part quickly using a few fasteners. But the experience proved even less dramatic than I might have thought, because upon our arrival on the floor, the assembly staff informed us that the stock of fittings made additively had been used. Team members were temporarily back to installing fittings that had been made the previous way, through machining. But I was told I might as well watch anyway, because the two fittings look identical. One is a direct, albeit more economical, replacement for the other.

In AM, we’ve seen certain misperceptions become less widespread. Early on, manufacturers looking to additive routinely wondered whether their current parts could be made more cheaply this way. The answer was almost always no, because current parts are designed for current processes. Additive is at its most effective when used to make a part designed for AM, leveraging the special design freedoms that AM alone can bring. This point has become more widely known. And yet, the 787 fitting underwent no redesign. In this case, additive did indeed deliver the lower-cost option for producing an existing part.

The correction to the previous misperception therefore deserves a correction of its own, or at least an asterisk: Sometimes, AM can cost-effectively deliver an existing part design. Sometimes, no redesign is needed. As a first step toward succeeding with AM as an option for production, manufacturers might do well to find the current parts fitting this description, the parts that want to be made additively even though a different process is making them now. The universe of such parts might be growing.

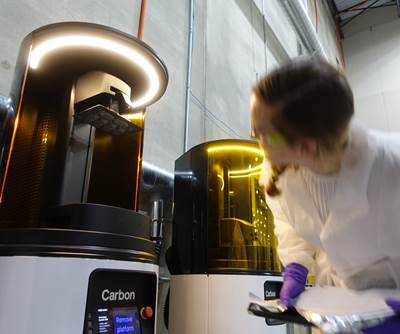

Resolution Medical is finding this out. Or more accurately, its customers are. Resolution is a user of production-oriented polymer AM technology from Carbon delivering build rates faster than conventional 3D printers and competitive with injection molding. Faster build speed reduces part cost, creating opportunities. As described in the story we recently posted, Resolution is now going to its customers to say, essentially, why don’t you let us avoid mold tooling and print the part instead? Again, little in the way of redesign is involved.

As a result, another misperception might also have been partly right. Manufacturers used to worry AM would take the place of conventional processes such as machining and molding. Most now know this isn’t true. And yet, in the case of the fitting at Spirit, in the case of various parts at Resolution, AM has indeed taken the place of a conventional process.

Even this much is not the full story. For that, see our article about Incodema3D. This company, which until now has been doing production AM for customers in fits and starts, has earned and begun to move forward with its first full-scale continuous-flow production AM job. Thousands of pieces per month will be made additively for this contract alone. And rather than replacing conventional manufacturing, this job brought it along. It commands not only metal AM capacity, but also the capacity of various CNC machine tools now committed to the parts’ secondary processing.

Production is arguably the most important topic in AM, because the advance of additive into production applications represents AM realizing its full promise. That advance is still early. However, successes are now numerous enough and far enough along to glimpse how production AM might play out. If we are learning some of the early misperceptions were partly valid, then this is only fair, because many of the early hopes are now being validated as well.

Related Content

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreRead Next

Incodema3D Reaches the Tipping Point for Production Additive Manufacturing

The New York manufacturer is launching into its first continuous flow production job for metal AM. Owner and CEO Sean Whittaker shares what it took to arrive here.

Read MoreInjection Mold or 3D Print? How Resolution Medical Pivots Production

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read MoreWhat Is the Role for Additive Manufacturing in Aircraft Structural Components?

Spirit AeroSystems recently began installing the Boeing 787’s first titanium structural component to be made through AM. The part is not critical but also not minor. I spoke with manufacturing leaders at Spirit about the meaning of the part and the way forward for additive in aircraft structures.

Read More