Prototyping

Researchers Develop High-Strength Aluminum Wire Feedstock for 3D Printing

IMCRC, AML3D and Deakin University’s Institute for Frontier Materials (IFM) have developed a high-strength aluminum wire feedstock they say can transform the way complex metal objects are manufactured.

Read MorePiab’s Small Vacuum Conveyor Safely Handles Metal Powders

Typical applications include metal powder transfer to or from a hopper or a sieve, feeding a 3D printer or recirculating material from the overflow bin.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

ListenChromatic 3D Materials Meets Flammability Requirements for Aerospace Industry

NIAR testing shows that multiple polyurethanes 3D printed by Chromatic are compliant with U.S. standards for use in aircraft interiors.

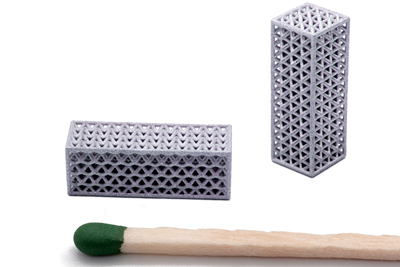

Read MoreStudents Use Micro Metal 3D Printing for ISS Microgravity Experiment

Qualified3D printed lattice parts for the students using microstereolithography (micro SLA), which seemed to be the only process able to produce the parts with sufficient accuracy.

Read MoreAM's Progress: How Far Additive Manufacturing Has Come in 6 Years

Tim Simpson reflects on how additive manufacturing has progressed since he began his column six years ago. Standards and software are two examples.

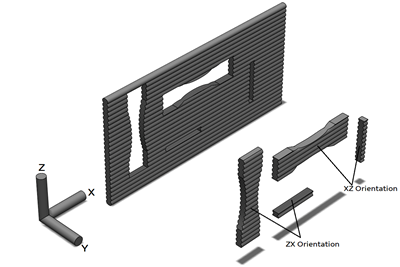

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreBraskem Acquires Taulman3D

The acquisition of Taulman3D further accelerates Braskem’s growth strategy in the additive manufacturing market with a complementary portfolio of 3D materials.

Read MoreAM Schedule Optimizer Enables Cost Optimization for Production Processes

Gravity Pull System’s Schedule Optimizer and Management software optimizes the additive manufacturing production process for cost and maximum machine utilization.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Watch