Students Use Micro Metal 3D Printing for ISS Microgravity Experiment

Qualified3D printed lattice parts for the students using microstereolithography (micro SLA), which seemed to be the only process able to produce the parts with sufficient accuracy.

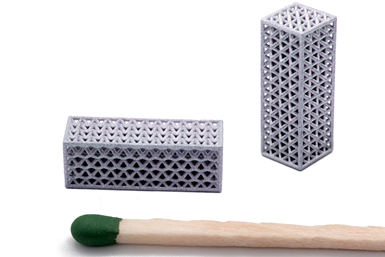

Stainless steel microlattice structures developed by VCS for an experiment on capillary action in microgravity on the International Space Station. Photo Credit:

When a team of high school students from the International Space Station Research (ISS) National Lab program at Valley Christian School (VCS) in San Jose, California, needed millimeter-scale lattices for an experiment on capillary action in microgravity, they turned to Qualified3D to get parts printed using microstereolithography (micro SLA).

Led by students Rohan Sachdeva and Daisy Zeng, the team designed lattices that had struts as thin as 0.5 mm in diameter, and micro SLA seemed to be the only process able to produce parts with sufficient accuracy.

While dimensionally precise, parts made from photopolymer resin were not an ideal match for the requirements of space flight due to their lack of resistance to vibrations, low temperatures and heat. Metal offered a better set of properties for the ISS experiment, but, unfortunately, the lattice design was not printable with conventional metal powder bed fusion and binder jetting 3D printing technologies.

Enter lithography-based metal manufacturing (LMM), a new 3D printing process which utilizes the principle of photopolymerization — where a metal powder is dispersed in a photosensitive resin and selectively polymerized by a Digital Light Processing (DLP) projector. This technology is capable of producing parts with extremely thin walls (125 microns) and smooth surfaces (2-5 micron surface roughness before polishing) in a variety of metals, including stainless steel and titanium.

Germany-based startup Metshape is recognized globally for its expertise in 3D printing and sintering LMM micro parts. It also sells its services to U.S. customers through Qualified3D. “Some of our students discovered that the miniature lattice design was printable using the LMM technology and proactively reached out to them,” says Emeka Okekeocha, ISS Program Manager at VCS. “After a technical review, we accepted the proposed change from acrylate resin to stainless steel.”

The students in the ISS Research Lab received their parts within a few weeks and are now looking forward to putting them to use for their experiment in microgravity. The experiment package should be launched up to the ISS in mid-February 2023 and should begin returning data in March 2023.

“We are very thankful to Qualified3D for how they always quickly responded to our requests and questions,” says David Kou, an 11th grade member of the VCS team. “Even with the many changes we requested, the parts were still delivered on time, which helped us to transition smoothly between planning and building our microgravity experiment.”

On a broader level, controlled capillarity in 3D printed metallic lattices is expected to open new technical possibilities in future outer space applications such as gas filtration, aerosol sample collection and temperature management. Another application is being able to passively control where water is in a container because, without this technology, it would be difficult to predict the location of the water in microgravity which has applications in plant growth.

- Listen to this episode of AM Radio to learn how 3D printing applications are playing a role in space exploration.

- Six reasons why space exploration will need additive manufacturing.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More