Prototyping

Molder’s Experience Illustrates How AM Will Interact with Other Advances

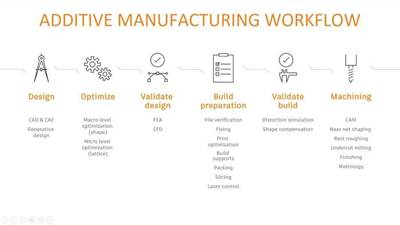

Additive manufacturing is not moving forward in isolation. It will leverage and work in harmony with other manufacturing technologies that are also moving forward.

Read MoreSuccessful Prints Require Feedback Before They Go to the Machine

DFAM is unlike designing for subtractive machining or injection molding, and requires acute understanding of the machine, process and materials involved.

Read MoreCaterpillar Leader Urges, Embrace AM for the Right Reasons

FOMO—fear of missing out—is not the right reason. Valid reasons to 3D print relate to cost or time saving and delivering value.

Read MoreProgress Toward a Model for DMLS

Research funded by America Makes is creating a model that will minimize thermal distortion in DMLS.

Read MoreHighlights from AM2016

At this year’s gathering in Chicago, presenters shared their insights and experience on the industrial application of additive manufacturing technology.

Read MoreAdditive Manufacturing Is Cyclical—Not Linear

The best use of additive manufacturing is in an integrated environment, says Benjamin Fisk of Methods 3D.

Read MoreDrilling Jig an Example of How 3D Printing Assists Machining

A machine shop benefits from 3D printing as a means of efficiently making custom hardware to aid both the process and the machines.

Read MoreWhy the Future of Additive Manufacturing May Be Hybrid Manufacturing

According to DMG MORI’s Dr. Greg Hyatt, additive and subtractive working in tandem is better than either approach on its own.

Read MoreThe Next Generation of AM Software Will Be Generative

Autodesk’s Amar Hanspal looks at additive manufacturing and the future of making things.

Read MoreEducators and Industry Discuss Need for Engineering Education to Adapt to AM

The National Forum on Additive Manufacturing Education and Training recently held at Penn State University yielded these interesting points.

Read More