Prototyping

Media Mix Finishes 3D Printed Plastic Components in Single Step

Because the new MJF/SLS media already contains an optimum mix of different shapes and sizes, the need for media changes in multistage finishing processes can be completely eliminated.

Read MoreBurloak Adds Capacity, Services with California Manufacturing Facility

Company also forms agreement with Carpenter Technology to collaborate on future product design and development opportunities.

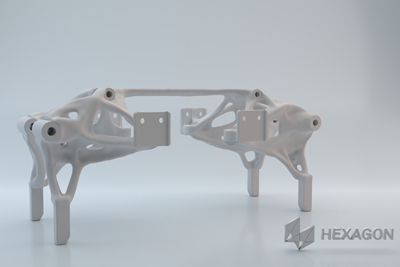

Read MoreImproving AM’s Efficiency with Generative Design

By engineering parts as opposed to designing them, MSC Apex Generative Design improves the efficiency of not only the final parts, but of the design and manufacturing processes as well.

Read MoreRenishaw, CCAT Partner to Accelerate Technology Adoption

Renishaw has provided industrial metrology and additive manufacturing equipment to the Connecticut Center for Advanced Technology Inc. (CCAT), as well as sales and applications liaisons for product demonstrations, webinars, training and support.

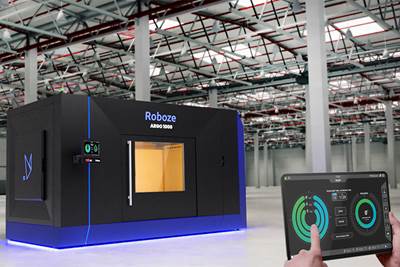

Read MoreRoboze’s ARGO 1000 Fabricates Large Parts Using Super Polymers, Composites

Printer uses more sustainable, high-performing super polymers and composites such as PEEK, Carbon PEEK and ULTEM AM9085F to reduce the strain on global supply chains.

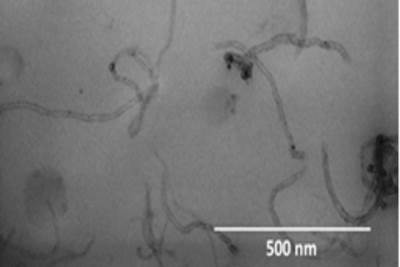

Read MoreUntangling the Promise of Carbon Nanotubes for 3D Printing

Recently emerged from stealth mode, Mechnano is bringing the promise of carbon nanotubes (CNTs) to life within various modalities of 3D printing. How these tiny additives deliver macro-level material improvements.

Read More3D Printed Cooling Bars Will Improve Observability of Antimatter

An experiment at CERN’s Large Hadron Collider (LHC) will be better able to detect the paths of particles thanks to efficient cooling delivered by metal 3D printed tubes.

Read MoreConcept Machine Tool Appointed Distributor for Farsoon Technologies

Concept Machine will serve as exclusive distributor for Farsoon’s metal and plastic laser powder bed fusion 3D printers and additive manufacturing products through nine states for sales, service and consumables.

Read MoreDesktop Metal Acquires Aerosint

Aerosint’s multimaterial printing unlocks a range of new applications for powder-based additive manufacturing solutions.

Read MoreIs AM in Competition With Conventional Manufacturing? Tooling Is on Conventional’s Side

Recent articles consider the other way additive manufacturing is advancing production: not by 3D printing parts, but in the ways 3D printed tooling makes casting, machining, molding and other processes better.

Read More