Prototyping

How Bridge Production Is Bringing New Possibilities: AM Radio #14A

Additive manufacturing makes bridge production a more natural factor in the production strategy overall. This has important implications for product development and even what products are possible.

ListenGE Additive Partners With Sydney University on Manufacturing-Focused Research Facility

The Sydney manufacturing hub is a new manufacturing-focused research facility that will work alongside industry to deliver cutting-edge R&D in additive manufacturing and materials processing.

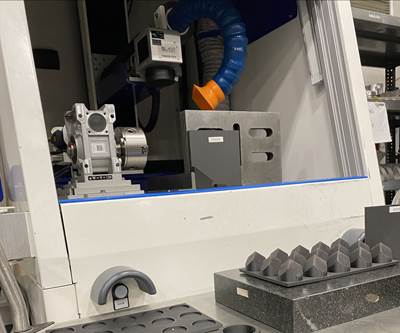

Read MoreFor Automated Machining Business, 3D Printing’s Value-Add Keeps Adding Up

Through robot grippers, assembly aids, custom kits and coolant hardware, additive manufacturing impacts every stage of production.

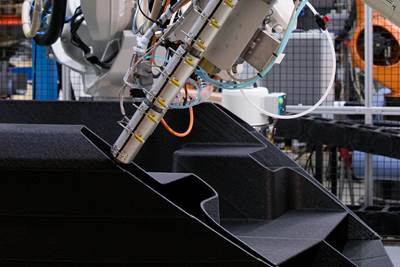

Read MoreThis Company Is Developing Software to Make Any Industrial Robot Into a 3D Printer

Do robots offer additive manufacturing capacity just waiting to be unboxed?

Read MoreRAPID + TCT 2022 Set for May 17-19

North America’s largest and most influential additive manufacturing event brings the industry together to help users discover real-world solutions to advance their manufacturing processes.

Read MoreCustom Canine Wheelchair From Carbon Fiber-Reinforced PP: The Cool Parts Show #44

A dog with a condition that affects her mobility gets a custom 3D printed wheelchair in this episode of The Cool Parts Show, enabled in part by a new polypropylene filament.

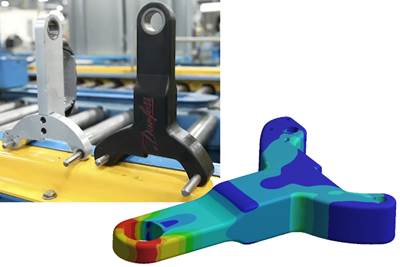

WatchWorkflow Validates 3D-Printed Composite Part Performance

A new workflow connecting 3D printing data with finite element analysis (FEA) enables simulations of fiber-reinforced 3D-printed parts that can predict mechanical and structural performance.

Read MoreMarkforged’s Precise PLA Expands Capabilities for Complete Product Life Cycle

Material expands Markforged applications from functional carbon fiber and metal parts to cost-effective design validation and rapid prototyping.

Read MoreStratasys Expands GrabCAD Software Partner Program for Additive Manufacturing

The new partners integrate with the GrabCAD additive manufacturing platform, adding manufacturing operating system and new product introduction 3D workflow software options for Stratasys customers.

Read MoreVacuum Cycling Nucleation (VCN) Removes Resin, Powders from 3D Printed Parts

Vacuum Processing Systems’ proprietary VCN process is well suited for parts with small holes and tiny passageways. A combination of vacuum and fluid clears uncured resin or unsintered metal powder. See it in action.

Watch