This article originally appeared on our sister site, Modern Machine Shop. Explore more about CNC machining at mmsonline.com.

“Anything that goes ‘boom,’” says Alan Soucy when asked to describe his company’s work. With customers including Lockheed Martin, General Atomics, Raytheon, Northrup Grumman and other large defense contractors, Advanced Precision Engineering (APE) is a very different manufacturer than the one Modern Machine Shop first covered in 1997. In addition to defense applications, the company’s then-specialty in semiconductor components provided a good foundation for transitioning into medical diagnostics equipment, prosthetics and communications assemblies, which can be no less challenging to manufacture than missile housings and firing controls. As Mr. Soucy puts it, “We don’t make brackets here.”

To maintain an edge with its largely West Coast customer base, this East Coast supplier has been investing millions of dollars annually in new equipment. The shop tour resulting in this story was too early to cover some of the latest examples, such as a 40-pallet system serving three of APE’s five-axis machining centers. Evidence of growth was plain to see nonetheless, including new HMCs, part-marking equipment and four collaborative robots capable of tending VMCs, live-tool lathes or any other machine tool not already fitted with a pallet changer.

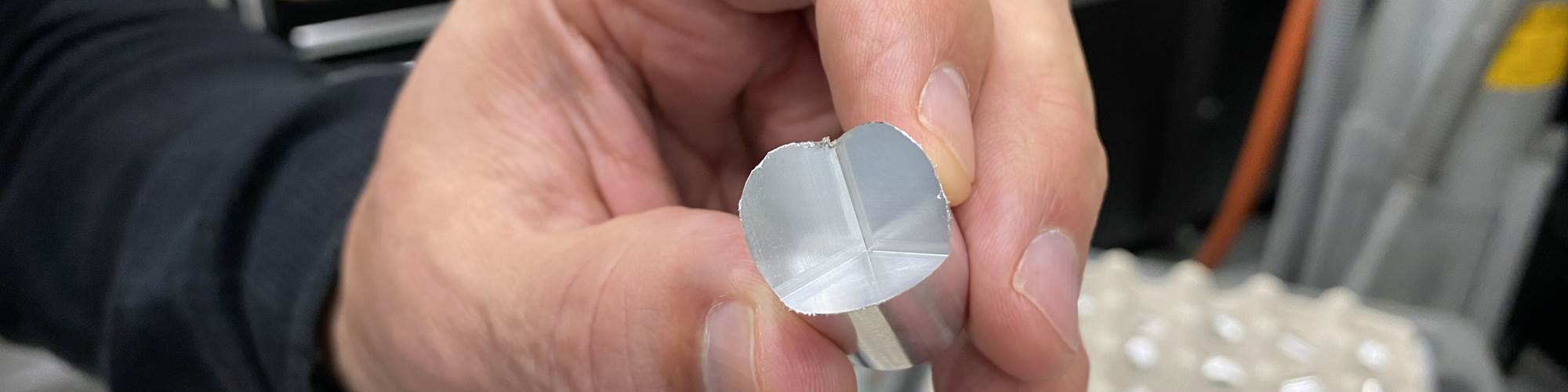

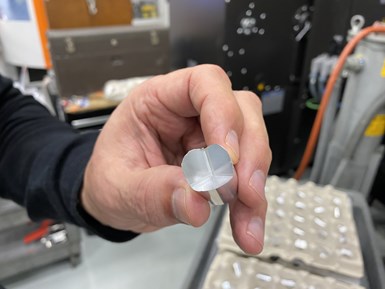

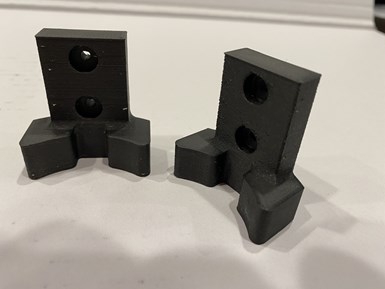

A closer look at the five-axis part for the fixture in the previous picture.

Despite all this new technology, conversations of any depth invariably returned to a less obvious development: the infiltration of additive manufacturing into every stage of the process. “It can be involved in everything you do in a machine shop,” Mr. Soucy says. “We keep finding new ways to use it.”

Agile Automation

Tucked away in an office area, APE’s Markforged X7 3D printer was installed in 2016 to complement the cobots. On-demand, custom grippers that mirror the workpiece geometry expands the range of work suitable for robotic machine tending, Mr. Soucy says. Meanwhile, the cobots themselves break their own barriers to automation. Lacking the complex programming and installation procedures of their industrial cousins, these arms can be wheeled as-needed to any workstation as long as the part quantity is high enough and the cycle time is long enough.

Grippers are designed from part CAD files to mirror the clamped geometry, which at APE generally involves contoured surfaces that would stymie generic end-of-arm tooling. Turnaround time for new grippers is generally overnight. For minor alterations of existing designs — say, adding material to a weak point identified during prove-out or a previous part run — a few hours is usually sufficient. The printer also produces models of the parts to enable proving-out gripper sets and robot paths as quickly as possible. In many cases, all of this work is completed before the raw material for the actual parts ever arrives on the shop floor.

Laying Kevlar reinforcement material can be challenging for programmers.

The gripper material is a variety of carbon fiber impregnated with varying amounts of reinforcing Kevlar, depending on the weight of the part, says Dana Laing, manufacturing engineer, who works closely with the additive machine. Strong but not brittle, this supplementary material ensures parts can be held securely without the gripper snapping under pressure. Two nozzles print these parts layer-by-layer, one of which is dedicated to the overall structure and the other to the strengthening Kevlar fibers.

In addition to tuning basic settings, such as the part’s orientation on the bed or the printing density, programmers must path the Kevlar reinforcement material through the specified sections of the gripper structure, Mr. Laing says. This task can be challenging with thin structures that cannot accommodate the fixed-width fibers.

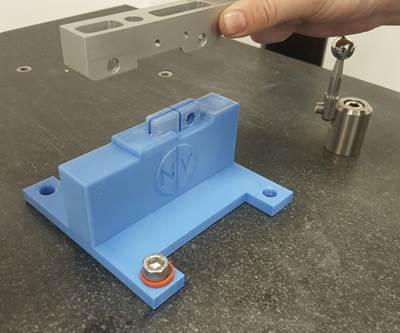

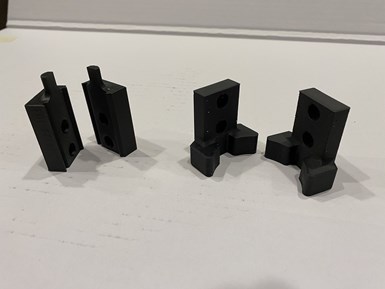

Common to every 3D-printed robot gripper at APE, the two holes interface with the robot arm. The rest of the geometry mirrors the part.

Other tuning might involve spacing the layers to resist certain forces (for instance, using a “sandwiching” effect to resist side flexing), or adjusting machine parameters such as build density or support structure geometry. Although literature and training from the machine’s manufacturer helped smooth the additive manufacturing learning curve, Mr. Soucy also credits the ingenuity of Mr. Laing and other members of his team (more on that below).

Additive Assists

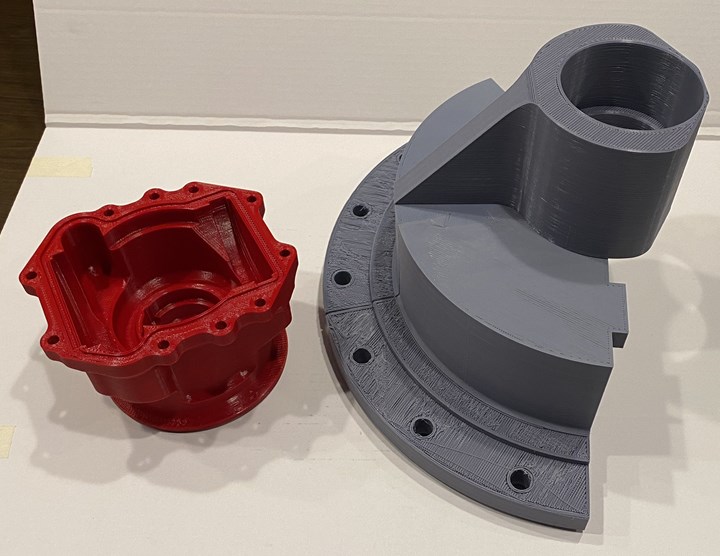

3D-printed replicas of new parts are always available for examination at the company’s regular, highly regimented process-planning meetings. During planning and quoting, this practice has been more beneficial than anyone could have imagined, Mr. Soucy says.

One of the most useful applications of additive is the one for which the earliest 3D printers were designed: prototyping. Models of new parts, like these, are always passed around during APE’s process-planning meetings.

Even with the most precise 3D CAD model, something as simple as part size can be easy to misjudge. “Sometimes, it’s like going out into a forest to choose a Christmas tree and thinking, ‘Oh yeah, this’ll fit,’ only to find that it’s much larger than anticipated,” he explains. “Or, you find yourself going, ‘Hey wait a minute, that’s a really small corner radius that’s really deep.’ Or, maybe you notice how a blended 3D surface comes right up to an edge and doesn’t give you the opportunity to use anything but a sharp-cornered end mill, which means more time surfacing.”

Experimentation with additive manufacturing also has led to a host of other new applications. Examples include:

- Gaging kits. Custom, 3D-printed kits carry all the measuring devices and other hand-held equipment required for a job. The quality control department receives an identical kit for validation. Each kit features nesting slots to prevent misplaced or lost tools or mistakes, such as choosing the wrong gage. As pictured below, each slot is labeled with the gage size, part-print “balloon” numbers for measured features, and other relevant information.

Shopfloor and quality control personnel receive custom, 3D-printed cases for all the hand tools needed for any new job. Photo: APE

- Coolant nozzles. Various shapes are not difficult to find on the open market, but 3D printing is faster and easier. Many cases involve extending coolant rings to prevent obstructions, such as VMC fourth axes, from blocking coolant, or printing fan-like shapes to ensure coolant reaches the cutting area.

- Coolant shrouds. These components prevent coolant or other debris from blocking tool-breakage detection lasers on the shop’s palletized machinery.

- Hose mounts. Shopfloor personnel can move 3D-printed, magnetized air-hose mounts like the one pictured below to any location that feels right for them.

Additive manufacturing makes shopfloor life easier.

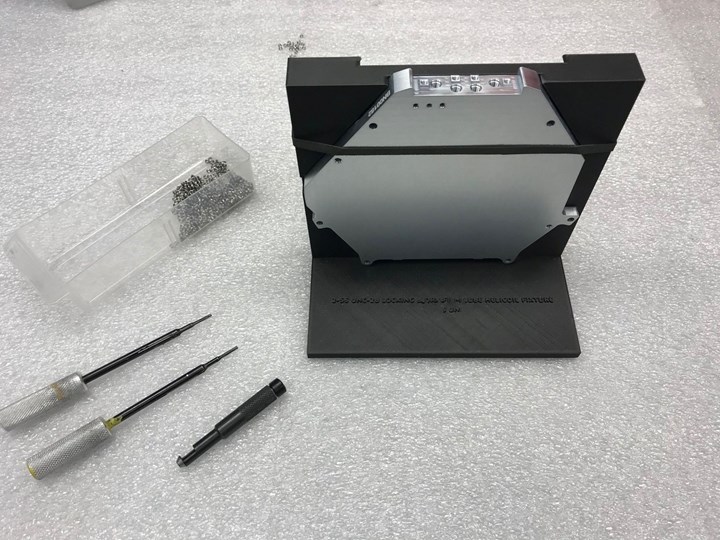

- Assembly aids. APE’s assembly personnel use various 3D-printed aids to prevent costly errors. For example, 3D-printed “masks” help avoid the risks inherent in installing helicoils (thread-strengthening components that require careful, manual insertion into machined holes). Any given housing might require multiple types of helicoils with different sizes and pitches, and avoiding mistakes is critical. “The housings we make for defense companies have super-critical surface finishes, and if you nick an edge, there’s no repairing it,” Mr. Soucy says. “The masks also expose only the holes that need the helicoils.”

Assembly aids are among the most useful applications of additive manufacturing at APE. This one is for inserting small inserts (helicoils) into threaded holes. Photo: APE

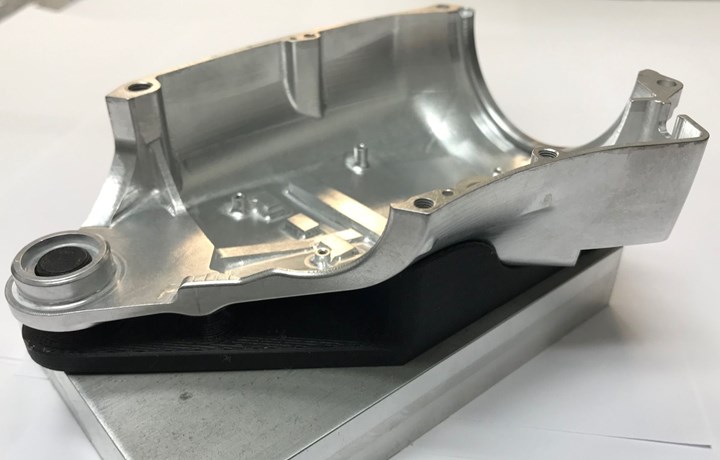

- CMM fixtures. As is the case with the robot grippers, fixtures that conform to part geometry help ensure mounting precision and repeatability. This is particularly important for CMM inspection. Consider a workpiece that must be mounted at an angle. The programmer might adjust the plane of the CMM program in order to check relationships between features. However, doing so might lead to a misreading of another callout. For instance, parts like the one pictured below often require certain levels of coplanarity among multiple surfaces. However, tilting the plane of reference to measure coplanarity might lead to an erroneous reading for the parallelism of those surfaces to yet another surface.

Given the complexity of APE’s work, CMM inspection would be more challenging without 3D printed grippers that mirror the part geometry. Photo: APE

Smarts and Hearts

These additive applications are only initial steps for APE, Mr. Soucy says. He hopes to begin printing machine fixtures as well. “When machines have 36,000-rpm spindles and move at 3,900 inches per minute, taking the weight out of the fixture puts less wear and tear on the machine axes,” Mr. Soucy says, referring specifically to the shop’s five-axis machining centers (Mikrons from GF Machining Solutions). “Another advantage would be if the operator is taking the fixture on and off the pallet to load another part. Removing unnecessary material on the fixture makes for a lighter fixture for the operator to handle.”

Making this happen will require technology that makes it easier to remove parts from the build plate without compromising flatness. Machining fixtures are not as forgiving as CMM fixtures, which generally exert less pressure. With APE’s current capability, 3D-printing fixtures would require machining surfaces smooth to ensure precise and secure part locating. Such work would occupy valuable capacity and defeat the purpose of 3D printing fixtures in the first place. Water-soluble supports are one possible solution the company is investigating, Mr. Soucy says.

The 3D printer itself seems modest, but it’s impact has been significant to say the least.

Longer-term plans include an entire additive manufacturing lab, which will be equipped to build end-use parts not only in carbon fiber, but also in metal. Confidence in the future of additive is well-founded because the shop has the right kind of people to move in this direction, Mr. Soucy says. This, in turn, is a result of a deliberate shift in hiring more than just skilled machinists.

For instance, seven employees are degreed mechanical engineers. Two have additive manufacturing machines at home, and both have contributed significantly to APE’s advance into this technology. As long as their employer supplies the material, they are happy to print anything on their machines that does not require the higher-quality material or higher precision of the machine at the shop.

However, Mr. Soucy emphasizes that skills and smarts aren’t enough to get a job at APE. From deburring personnel to engineers, “We hire good hearts,” he said during an initial phone call about the prospect of telling another story about APE more than 20 years after the first MMS article. This was his first response when asked to detail the “change in philosophy” he cited as the biggest difference between now and then. Pride in the work is another important attribute in any new hire, as is emotional intelligence. “People who work here care about each other and take ownership of everything they do here at APE, and that’s really changed the company,” he says. “We spend eight to 10 hours a day with each other, and it makes it easier to come to work each day when you have people that have their team’s back.”

Related Content

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreCombining Metal and Polymer for Better 3D Printed Tools

Applications prone to wear call for more durable tooling than 3D printed polymer alone, but full metal is not always necessary.

Read MoreRead Next

Moldmaking Water-Flow Simulation Makes 3D-Printing Practical

Virtual prove-outs prove the worth of stirring things up, both within the cooling channels of individual molds and in the plastics industry at large.

Read MoreCMM Inspection Aided by 3D-Printed Fixtures

Cincinnati Inc. has found that 3D-printed fixtures save money and effort in the inspection process for intermediate to complex machined parts.

Read MoreAdditive Manufacturing Belongs in a Machine Shop

A fourth-generation family machine shop integrates metal additive manufacturing as another production operation.

Read More