Prototyping

Desktop Metal’s Robotic Additive Manufacturing System for Sand Printing

The ExOne S-Max Flex system use single-pass jetting technology to deliver 3D printing at high speeds for low-cost parts.

Read MoreCapture 3D’s Small, Portable GOM Scan 1

The company says the scanner is well suited for digitizing small- to medium-sized objects in high-quality data.

Read MoreStatus Check: Repeatable and Distributed Manufacturing in AM — Ready Yet?

With potential drift and IP barriers, is metal additive manufacturing ready to contribute to distributed manufacturing?

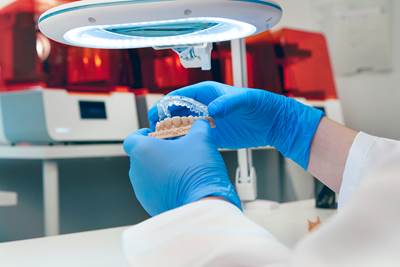

Read MoreFormlabs Dental, Medit Collaborate to Streamline Chairside 3D Printing

Combining their technology is said to enable clinicians to easily 3D print dental components with greater speed and efficiency through a simplified in-office workflow.

Read MoreThe Second Wave of Disruption: From “How Do I Design?” to “How Do I Scale?” (Video)

Serial additive manufacturing business founder Greg Morris on changes in the understanding of AM over time.

WatchGE Aviation Invests in 5 M Line Metal Additive Production Systems

The system is designed to enable customers with large part size demand to increase productivity and reduce cost for additive production.

Read MoreKent State, Iten Industries Partner for 3D Printing Education

Iten Industries’ goal is to drive internship and engineering experience in the area with students getting hands-on experience with the company’s additive manufacturing printers.

Read MoreSiemens Opens Charlotte Advanced Technology Collaboration Hub

Siemens says it will use this research and development space to collaborate with key OEMs, end users and U.S. national laboratories to help advance the successful industrialization of additive manufacturing.

Read MoreArburg Freeformer Machines Produce Complex, Functional Parts

Rapid + TCT 2022: Arburg’s Freeformer machines feature an open system enabling the properties of the additively manufactured parts to be specifically adapted.

Read MoreAdditive Manufacturing to the Rescue — Again

AM is the perfect candidate to solve production problems that began during the pandemic.

Read More