The Second Wave of Disruption: From “How Do I Design?” to “How Do I Scale?” (Video)

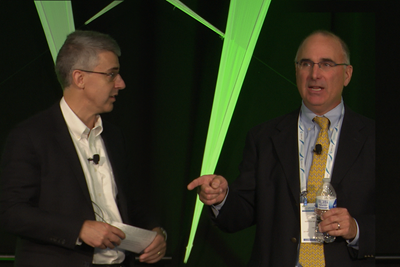

Serial additive manufacturing business founder Greg Morris on changes in the understanding of AM over time.

Share

Read Next

Vertex Manufacturing is the second business thriving with additive manufacturing that Greg Morris has co-founded. The first was Morris Technologies, which was acquired by GE. What has changed in the view or understanding of AM from the time of the first company to the time of the second? Morris reflected on this in a conversation he and I had as part of the Additive Manufacturing Conference in 2021.

Editor’s note: Vertex Manufacturing is now part of Zeda, Inc.

Transcript

Audience Member

We talk about additive as a new disruptive technology but it's pretty old now. What have you seen? What's been the sea change in additive? Greg kind of hinted at this that we'd get to it and I knew we would but what's been the disruption for additive production?

Peter Zelinski

What has changed, as someone who has stewarded now two different businesses delivering additive, but also to the question Justin asked maybe what have you seen recently disrupting this disruptive technology?

Greg Morris

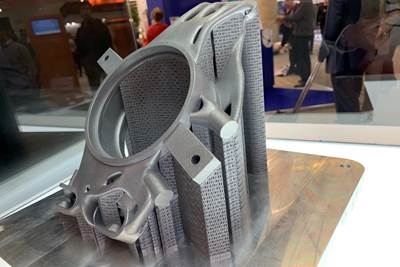

So I think it's a great point. And and by no means do I think I have the answer for all that question. There's probably a lot of opinions out there. So I'll try to give you mine at least. First, I would say that the technology still continues to be somewhat disruptive. And I think, when when we look back, the obvious people who started to take advantage of the technology were, again, some of these guys who had real complex geometries that they could benefit using the technology, or they had materials that were particularly conducive. So titanium, inconels, cobalt chromes, etc. So those made it very conducive to use the technology. So that was kind of the first wave, at least that I saw. And back in the Morris Tech days, it was really a huge amount of just explaining what the heck the technology was, what was this complex part and how it was made. That was where we were back then. I was just talking to somebody this morning about that. It used to be you'd go to a show like this, you'd have these complex parts, and you would have traditional manufacturing folks come up and go, How in the world did you make that? That doesn't happen anymore. That's gone. And most times people come up, they know exactly how it's probably been made. They might not know exactly what machine it was made on, but they got a good idea of how it was made. So we've switched now to where over the course of I would call it the last 10 years. We're moving from the novelty of how do you design for it? And that's still out there as well. But now, how do I scale? How do I manufacture this thing in a way that I can get the price points, and I think that's one of the disruptions, hopefully, that's coming is that we're starting to see technologies, machines and technologies and advancements that allow us to start to hit price points maybe, that make it a technology that you can actually go produce 100,000 pieces on. And you're starting to hear, hey, I need 60 machines, I need 100 machines to produce my widget. My widget might be 300,000 pieces I need to produce. Those are the conversations that are starting to happen today. And what's the most efficient layout? What are the best machines for that? So I think that's the disruption that I see and we're not quite there across the board. I still think we have a way to go before we can say that I can compete against the traditional manufacturing methodology. But when you combine design for additive, which can be put in its own box right, now you can't cast it, you can't fabricate it, you can't machine it any other way besides additive, then you need to start to switch into the conversation around cost. And cost to me is going to be one of the focus areas, it is one of the focus areas in the industry. But we have to start to see that continue to come down in one form or another in order to have these opportunities to see higher volume mass production.

Related Content

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

Additive Manufacturing Is More Than 3D Printing: The Importance of Complementary Capabilities (Video)

Vertex Manufacturing founder Greg Morris on machining, inspection and other operations that complete AM.

Read MoreRecapping the 2021 Additive Manufacturing Conference + Expo: AM Radio #5

The program covered everything from tooling to personnel challenges involved in implementing additive. Peter Zelinski, Stephanie Hendrixson and Julia Hider recap the event.

Read MoreAM So Far: A Conversation on 10 Years of Covering Additive Manufacturing: AM Radio #11A

Additive Manufacturing Media marks its 10-year anniversary. AM Radio hosts Stephanie Hendrixson and Peter Zelinski look back, talking about the advance of industrial 3D printing and expansion of the ways we report on it.

Read More