Kent State, Iten Industries Partner for 3D Printing Education

Iten Industries’ goal is to drive internship and engineering experience in the area with students getting hands-on experience with the company’s additive manufacturing printers.

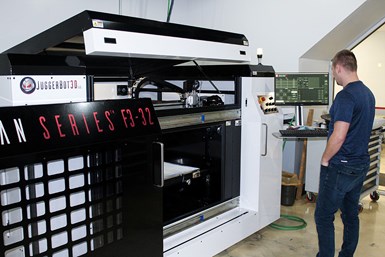

Devin Curtis, Iten quality engineer, prepares a build on the Juggerbot 3D Tradesman SeriesTM F3-32. Photo Credit: Iten Industries

Kent State’s Ashtabula and Tuscarawas campuses are teaming up with Iten Industries for a 3D printing and manufacturing education program, which is designed to give students hands-on experience with Iten’s 3D printers.

“The direction of engineering technology and future success is in 3D printing, and our goal is to drive internship and engineering experience in that area,” says Ron Emery, business development director at Iten Industries.

Starting this fall, students can take eight courses in the proposed 3D printing curriculum. Courses include engineering drawing principles, 3D modeling introduction, polymers, manufacturing processes and more. The courses are currently taught as part of the Tuscarawas engineering technology degree programs, which include associate degrees in electrical/electronic engineering technology, mechanical engineering technology and technical modeling design, as well as a bachelor’s degree offering several engineering technology concentrations.

This program is the first step in potentially developing a certificate or “stackable credential” in 3D printing and manufacturing that would transition into the associate and ultimately bachelor’s degree programs. “We’re looking at the future of our workforce and the transition of industry in Ashtabula County,” Emery says. "Iten has been very successful now for over 100 years, but we’re looking at what will drive us in the future and we believe it will be in 3D printing.”

Iten is headquartered in Ashtabula and manufactures thermoplastic and thermoset stamped, molded and machined plastic parts, producing over 215 million components each month. The collaboration with Kent State includes a state-of-the-art laboratory for emerging technology within school’s College of Applied and Technical Studies as part of Kent State Tuscarawas’ engineering technology program.

“3D printing is an emerging field that people are really interested in,” says Michael Czayka, an engineering senior lecturer at Kent State. “Iten is positioning themselves as a leader in this field and it’s exciting to work with a local company as an institution to provide a pathway to education in a field that is hot and in-demand right now.”

“We’ve invested heavily in recent years in 3D printing and in advanced computer numerical control (CNC) equipment,” Emery says. “These advances cut down on engineering development time, cost and time-to-market for us and our customers.”

Iten currently has on-site a JuggerBot 3D Tradesman Series F3-32 filament fabrication system that can create builds as large as 36" by 24" by 36". The company says it is adding a pellet-extrusion machine, a JuggerBot P3-44 model said to be three times the size of the current 1,200-lb printer with a build area of 48" by 36" by 48".

“These new machines allow us to rapidly prototype parts for customers so they are able to look and feel how a product may look when we are helping the customer conceive a product,” says Devin Curtis, an Iten quality engineer who specializes in AM and Ramp Armor sales. “We’ve also used the machine to make custom jigs for some of our smaller injected molded parts, so they can be measured with our digital comparator, which allows us to speed up the process of measuring parts for our quality checks.”

Curtis says that AM is opening up new possibilities in a variety of industries, including medical equipment, surgical and prosthetic industries. “We’re on the verge of an industrial revolution, as this technology opens up these possibilities for anyone,” Curtis says. “All it takes is one to have an idea and run with it.”

As with any new technology, there can be a considerable learning curve to getting good results with different processes and materials, the company says. Coming into the industry with prior 3D manufacturing education and experience has significant and measurable advantages.

This means the educational program has the potential to impact the plastics industry throughout the region. “Our footprint is growing and we’re using equipment no one else has, developing cool technology no one in this area utilizes and it’s leading to increased production,” Emery adds. “But we need people with experience and knowledge to run the equipment.”

Note: For more information about Iten Industries, read “3D Printing at the Turn of Iten’s Century.”

Related Content

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read More6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More