Production

For Stratasys, Acquisition of Origin Part of Strategy Focused on Production and Polymer Materials

Americas president Rich Garrity describes how the two additive manufacturing technology companies came together (COVID-19 helped), along with the value of protecting one culture while allowing another to change.

Read MoreSolukon Upgrades Automated Powder Removal Units for Large Parts

Systems are now reinforced to handle larger parts and feature a joystick to improve and individualize controlling, and an optional impactor system for breaking up clogged powder bulks.

Read MoreBell Textron, Ingersoll Machine Tools Produce 3D Printed Rotor Blade Trim Tool

Collaborative effort successfully manufactured a 22-foot-long vacuum trim tool for production of main rotor blade components.

Read MoreInkbit Vista 3D Printing System Offers Vision-Controlled Jetting Solution

Developed at MIT, this highly automated 3D printing system features closed-loop feedback control, multimaterial printing capabilities and low cost-per-part for final part production.

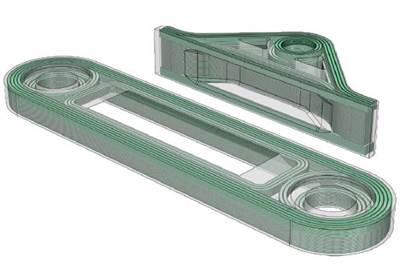

Read MoreFiber-Reinforced 3D Printing Expands Control, Applications for Composites

9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste, and more precisely control the structure of preform composites.

WatchAMEXCI, SLM Solutions Strengthen Collaboration on AM Application Studies

AMEXCI invests in the SLM500, a selective laser melting machine, for application studies to further accelerate the industrialization of metal-based additive manufacturing (AM).

Read MoreXact Metal Partners with GoEngineer for Sales, Service Support

GoEngineer to provide sales and service for Xact Metal to customers in western United States.

Read MoreMore Than Meets the Eye to Cobra’s 3D Printed Putter

Cobra Golf drew attention in November 2020 with the launch of a limited-edition putter with metal 3D printed head. What this club says about product development, reshoring manufacturing and the future of consumer goods.

Read More3D Control Systems’ Zap Workflow Software Integrates Disparate 3D Systems

Software eliminates cost variables through integration of all components to provide seamless automated interaction, resulting in reduced time and cost.

Read MoreWhy Dig a Pit in an Additive Manufacturing Facility?

Additive Engineering Solutions moved two of its BAAM 3D printers out of the way and began to dig a hole in the floor. How going lower allows AES to build higher.

Watch