Metal

HAMR Joining Neighborhood 91 Additive Manufacturing Production Campus

HAMR will join Neighborhood 91’s existing additive manufacturing ecosystem which includes tenants Wabtec, Arencibia, Cumberland Additive and Metal Powder Works.

Read MoreDesktop Metal X-Series for Metal, Ceramics Additive Manufacturing

The X-Series is said to offer a differentiated approach to binder jetting enabled by Triple ACT — an advanced compaction technology for dispensing, spreading and compacting powders during the binder jet printing process.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreSpee3D’s Metal 3D Printer First in World to Print Parts on US Naval Ship

Spee3D’s WarpSpee3D additive manufacturing technology was successfully used in the U.S. Navy’s REPTX exercise, which serves to demonstrate and evaluate the viability and efficacy of products and services that could expand the Navy’s ability to perform expeditionary maintenance operations.

Read MoreFarsoon FS200M×2 System for Optimizing Productivity, Turnover Rates

The company says the printer is well suited for medium- to high-volume metal series production and prototypes.

Read MoreMultimaterial 3D Printing with Conventional Powder Metallurgy

Unbound sand serves as temporary, reusable molds for metal powders in Grid Logic’s 3D printing process.

WatchVelo3D Qualifies M300 Tool Steel for Use in Sapphire Printers

The company says the high-strength alloy combined with Velo3D’s end-to-end solution can improve the lifetime of tooling inserts and enhance manufacturing throughput for automotive manufacturers.

Read More6K Additive Partners With Incodema3D for Powder Supply, Recycling

6K Additive says its nickel alloy 625 powder surpassed every quality measure in tests performed by Incodema3D.

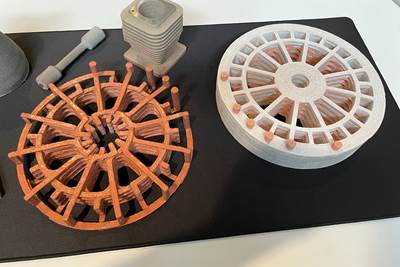

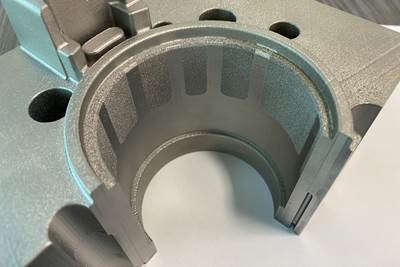

Read MoreDrop-In Solutions Give Users the Benefits of 3D Printed Mold Tooling

3D printed mold components, including ejector pins with venting to eliminate gas traps, can improve performance of traditional injection mold tooling.

Read More25 Years Later, What’s Exciting in Electron Beam Powder Bed Fusion?

Often seen as runner-up to laser powder bed fusion, are we finally in the golden age of the electron beam?

Read More