One major hurdle for the adoption of 3D printing is convincing manufacturers to adopt a new process. “The biggest challenge is just people seeing what’s possible,” says Jason Murphy, director of business development at additive tooling company Next Chapter Manufacturing.

3D printing enables the addition of conformal cooling channels to mold tooling. This can reduce molding cycle times significantly, especially given that cooling a mold can account for as much as two-thirds of the cycle time.

This is especially true in difficult business conditions, such as the ones injection molders are currently experiencing. “Resin costs in the last 18 months have tripled or quadrupled. That’s crushing to an injection molder,” Murphy explains. “A lot of times, they’re the ones that are absorbing that, and they’re not as easy to pass on to their customer.” This has led molders to start using new materials, including recycled materials and bio resins, which can be more challenging to process. They could be more difficult to cool, or more likely to result in defective parts due to heat degradation, inconsistent regrind size or gas traps. As companies switch to these materials, they’re running into new problems with their existing molds.

But even as molders are looking for solutions that will help them run these materials, they often aren’t in a position to take the risk of 3D printing new molds or retrofitting existing ones. “When you look at those factors, people are not going to say, ‘Oh, let's try something completely new,’” Murphy notes. He says that Next Chapter is seeing increased demand for solutions such 3D printed mold components, including its 3D printed InnoVent ejector pins, which give users the benefit of 3D printed mold tooling without starting from scratch.

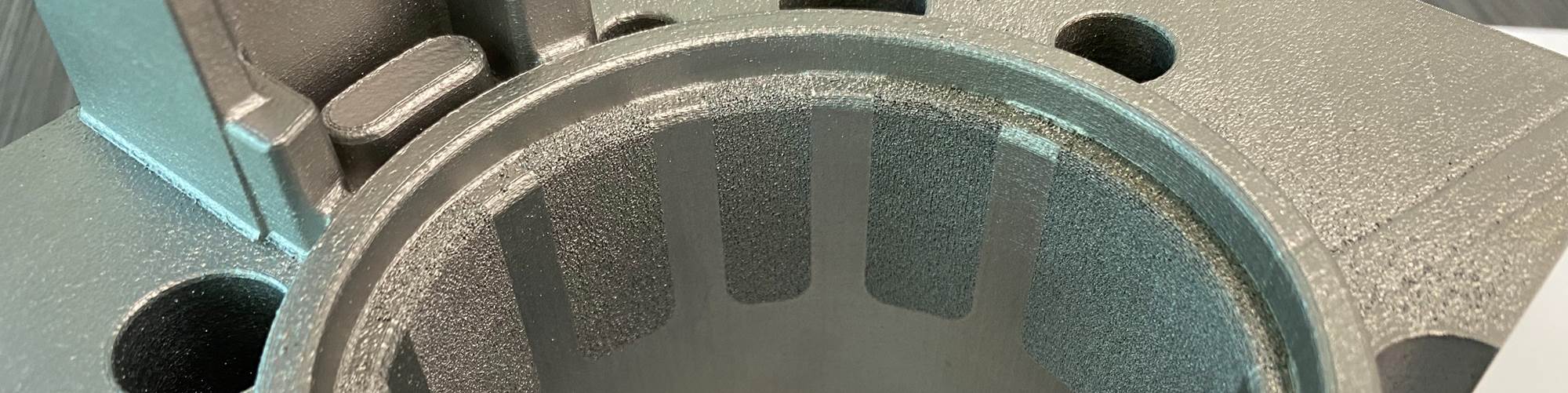

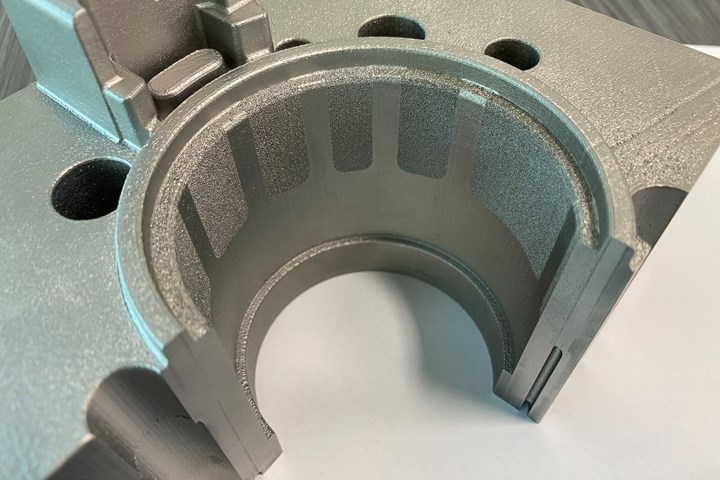

Next Chapter Manufacturing also uses 3D printing to add porous areas to mold inserts, which reduce part defects by venting gases out of the mold. This optimized design, called InnoVent, is 10 to 100 times more effective at venting than traditional solutions. Photo Credit: Next Chapter Manufacturing

The Benefits of 3D Printed Tooling

Next Chapter Manufacturing specializes in 3D printed tool steel injection molds, die cast dies and mold components using laser powder bed fusion. “We take data and analytics, and we design the tools with conformal cooling and sintered venting integrated in,” Murphy explains. “This enables us to build the most efficient tooling possible.”

The two 3D printed features that Murphy mentions, conformal cooling and sintered venting, provide different benefits.

Conformal Cooling

Conformal cooling channels can reduce molding cycle times by as much as 80%, according to Murphy. And because cooling can account for as much as two-thirds of a mold’s cycle time, the time savings can be significant, particularly in high-volume industries such as packaging.

Sintered Venting

Sintered venting, on the other hand, has the benefit of reducing part defects, which is crucial in industries with strict quality standards, including medical. Sintered venting accomplishes this by eliminating gas traps, which are a major source of part defects.

Gas traps occur when an injection mold is filled with plastic, and the air that’s already inside the mold is displaced. Molds need venting to let this air out, and the holes in these vents need to be very small so as to not let the plastic escape the mold. “We're talking micron level, or tenths of a thousandth in a lot of cases,” Murphy says.

One typical venting solution is to make molds from blocks of porous, sintered material. But this results in molds with thick sections of porous material between the inside of the mold and the atmosphere outside of it. These long, tortuous, narrow chambers can get clogged, particularly when materials have additives such as flame retardants, flow additives, lubricants and release agents that leave residues.

Another solution is to grind flats onto the sides of a mold’s ejector pins, so that gas can escape through the extra space between the pin’s flat sides and the mold. However, residue can also get trapped and build up in these spaces, eventually causing the mold to wear out as the pins move. The residue can also make its way onto the parts, leaving marks and contamination where the pins contact the parts.

Optimized Venting

Next Chapter Manufacturing uses 3D printing to produce molds with optimized venting. “In very specific and precise areas, we're able to change the density of the steel using the laser bed fusion process, and actually make certain areas porous,” Murphy explains. The company has developed a venting design, called InnoVent, that addresses the issues with traditional venting solutions. Unlike with blocks of porous material, InnoVent’s porous structure is specially designed for venting. A thin layer of the metal on the inside of the mold contains pores small enough for gas to escape without letting out any of the material. These pores lead to wider channels that are designed to vent the gases out to the atmosphere as fast as possible without clogging. According to Murphy, InnoVent technology produces anywhere from 10 to 100 times more venting than traditional solutions.

InnoVent also solves another limitation of conventional venting solutions. Traditionally, features on a mold can be cooled or they can be vented, but not both. “The beauty of the InnoVent technology is we’re actually able to put venting in right next to the conformal cooling,” Murphy says. With 3D printing, Next Chapter can control the placement of the sintered vents precisely, so that they don’t interfere with the conformal cooling channels, causing them to leak. This allows users to gain both the benefits of reduced cycle times and reduced part defects. He described one sample part the company had recently run. The part was large, with around 50 ribs. Thanks to a combination of conformal cooling and InnoVent venting, cycle times were reduced by 38% and had no defects. “They would have probably struggled for weeks or maybe months trying to eliminate all those gas traps as they qualified the tool,” he says.

The company works with customers to design and produce new 3D printed molds with these features, as well as retrofitting existing molds. This could involve cutting up an existing mold and rebuilding certain sections with venting or conformal cooling channels, or building new sub inserts for an existing mold.

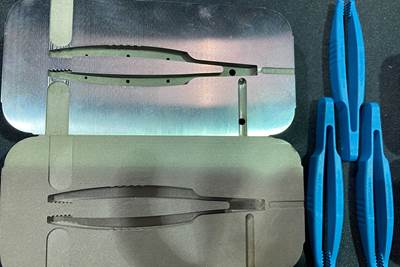

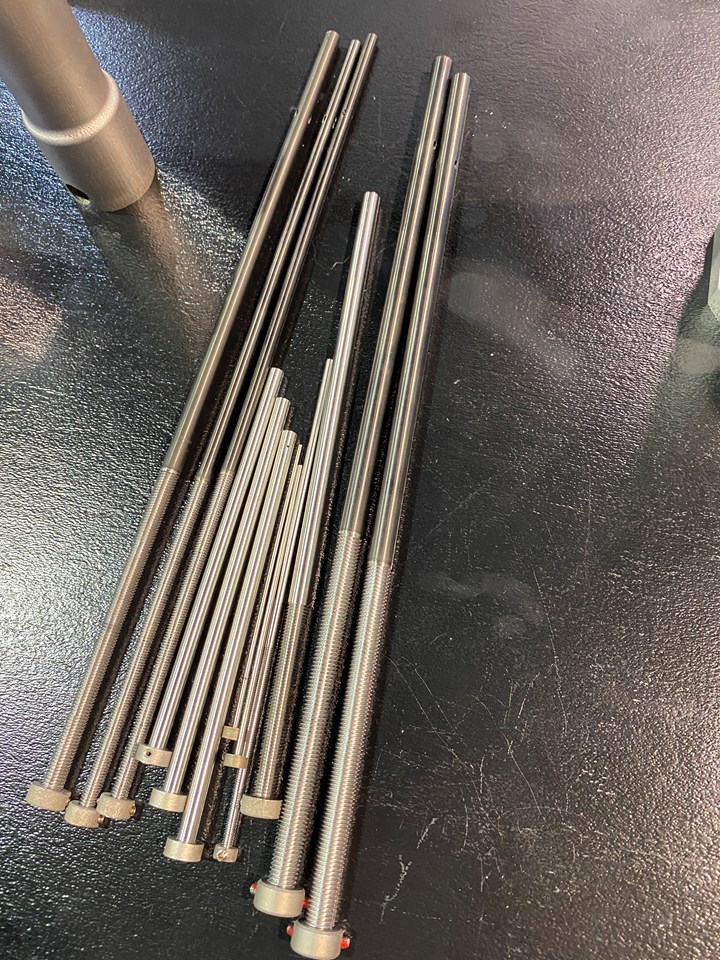

Next Chapter applied its InnoVent design to ejector pins, giving molders a way to reduce part defects without building a new mold or retrofitting an existing mold.

A Cost Effective Solution

Next Chapter Manufacturing also 3D prints mold components. “The first additively manufactured standard mold component we produced years ago was our sprue bushings,” Murphy says. “We took a sprue bushing, we put conformal cooling in it and offered it as a standard, drop-in, off-the-shelf replacement.”

The company wanted a way to offer its InnoVent technology to more molders as well. It started with customers asking for 3D printed bricks of material with InnoVent venting that they could machine into molds. Next Chapter determined that this wouldn’t be efficient to print, but it came up with a solution that is. “We ultimately settled on the ejector pin because most every mold has a pin, sometimes up to 100 or 200 pins on a mold, and those pins are strategically placed throughout the mold,” Murphy says. “They're typically put where the where the gas is going to be trapped at, like the end of fill.”

The InnoVent pins, much like the InnoVent technology that’s integrated into 3D printed molds, are optimized for venting gases out of molds. Instead of grinding flats onto traditional ejector pins to vent gases out around the pins and dealing with residue build up, the InnoVent pins vent gases through the center of the pin, leaving the outside of the pin clean and able to be coated with lubricant so it doesn’t wear out the mold. Murphy says that the pins will last through a full preventive maintenance cycle, at which point users can pull the pins out and clean them. They can be cleaned along with other mold components using a number of processes that are already available to molders, including ultrasonic cleaning, acetone or baking.

Like Next Chapter’s 3D printed mold tooling, the InnoVent pins are made from 3D printed tool steels with the possibility to add surface treatments and coatings. The pins are currently available in 56 sizes, with more on the way. And if a molder needs a size that’s not currently available, Murphy notes that the pins can be easily and quickly modified to the correct size.

Murphy says that the company is able to produce the pins very efficiently, the result of its focus on lean additive manufacturing. He also notes that it can add pins to build plates when printing other parts. “The more you put on a build plate, the faster it prints, right?” he says. “So this is something that we're really leveraging.”

Custom, 3D printed solutions for injection molders remains the core of Next Chapter Manufacturing. “But I think the fact that we can offer a standard off the shelf component is really, really vital,” Murphy adds, especially for companies that need to solve their problems quickly and don’t have the time for custom applications. At most, for the InnoVent pins, users will have to ream a hole to install the pin. He says, “I think this is a good compromise to get the most cost effective solution.”

Related Content

Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreRead Next

3D Printing Enables Mold Shop to Rapidly Prototype Medical Parts (Video)

A case study involving Mantle’s 3D printing technology allowed moldmaker Westminster Tool to go from design to injection molded prototype medical parts in three weeks.

Read More3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Read MoreMicro 3D Printer Complements Micro Moldmaking Capabilities

For micro mold provider Accumold, the Nano Dimension 3D printer provides a way to produce micro-scale prototypes and rapid tooling.

Read More