Grid Logic’s multimaterial powder bed process uses sand to build up a support structure for metal powders. The system above is currently printing with three material feeders inside a removable build box suitable for the part size. The printing process uses no heat or binder; when the build is complete, the entire box will go on to sintering in a separate step. Photo Credit: Grid Logic

Metal 3D printing has long been seen as an alternative to powder metallurgy (PM), but the processes are fundamentally different. Where casting requires tooling, 3D printing needs none — this offers an advantage in terms of geometry and lead time, but it also means that parts are built in layers, bit by bit, instead of all at once. In high-energy 3D printing processes that rely on the power of a laser or electron beam working point by point, different areas of the build can become hotter than others and introduce thermal stresses not common to PM parts. In laser powder bed fusion in particular, part features often require support structures, extra material that will later need to be removed. And for both LPBF and EBM additive manufacturing (AM), powder materials can be expensive and diverge from conventional metallurgy.

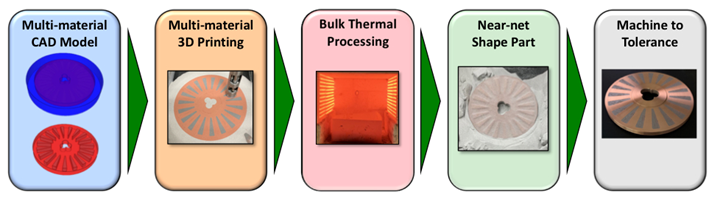

Grid Logic believes it has a solution to the challenges of both powder metallurgy and other forms of metal 3D printing with its multimaterial powder bed process. The 3D printing technique uses conventional metal powders, but leaves the melting of these materials to a separate furnace in a step that happens after printing. The material deposition can therefore take place at room temperature, in machines that consume low amounts of energy. Sintering happens all at once, avoiding the creation of hot or cold regions that can introduces stresses. The powder’s inability to support itself isn’t a challenge either: Rather than support structures, the company’s technique involves simply printing sand around the loose powder that will form the part.

The process is a bit like foundry casting, if the materials for the tooling and the part were placed roughly simultaneously. Every Grid Logic 3D printer has at least two material feeders so that sand can be deposited alternating with the metal powder. The sand serves as a temporary support, but unlike other kinds of sand foundry tooling, here there is no binder — meaning that this tooling material is infinitely reusable. After the full build box goes through sintering and the final metal parts are excavated, the sand can go straight back into the printer.

The full process from design to finished part with multimaterial 3D printing. Bulk thermal processing takes the place of point-by-point or layer-by-layer sintering, making the 3D printing process safer and easier; end-to-end, Grid Logic’s process delivers a final metal part in only a few steps. Image Credit: Grid Logic

The technique allows for many of the same lead time and geometric benefits provided by other metal 3D printing processes, but avoids many of the challenges associated with melting or sintering point by point and layer by layer. Other advantages include no hard limits on build size (the build box can be as big as necessary), self-leveling by virtue of the flow of the powdered material, and no need to wait for a preheat cycle or maintain high temperatures in the build envelope.

Co-founded by brothers Matt and Jim Holcomb, Grid Logic first premiered its multimaterial 3D printer at RAPID 2021. The company’s goal, however, is not to supply machines at the moment but instead to provide parts as a faster, more flexible alternative to conventional PM and casting. Its Lapeer, Michigan, facility is currently equipped with six multimaterial powder bed printers and three sintering furnaces, plus a selection of lab and other postprocessing equipment. Larger parts and those requiring steps like hot isostatic pressing (HIPing) are sent off site when necessary.

Identifying the right parts and markets for this additive technology is an ongoing process, but the Holcombs see particular opportunities in materials that are well-understood for powder metallurgy but difficult to 3D print through other methods. These include copper and refractory metals such as tungsten and molybdenum, which tend to reflect the beam of a laser but pose no such difficulty when sintered. Even ceramics, which require very high temperatures to melt, can be used directly in this process with no need for a slurry or other intermediate material format. Additional materials used include aluminum, steel and bronze, the latter of which can be printed alongside and infiltrate other metals during sintering. By removing many of the material challenges with 3D printing, Grid Logic can focus more on geometric possibilities.

“We’re so familiar with powder metallurgy that we just need to control where the powder is,” Matt Holcomb says.

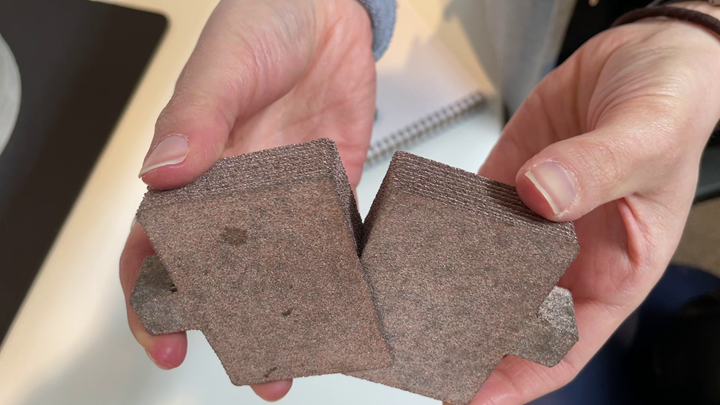

“We’re not printing 50-micron layers,” says Jim Holcomb, but nonetheless the Grid Logic process can deliver a surprising amount of detail. These demo parts were actually printed together, as an assembly; their thin fins slot together to show how precise features can be.

The G-code that drives the nozzles is generated by software developed in-house; once established the toolpaths can be manipulated to speed printing, for instance building up several layers of sand for the support before filling the void with metal, or reducing the support footprint along with the part where applicable. The sintering, which takes 4 to 12 hours, is typically the slowest step.

End to end, the process is fast — almost certainly faster than conventional PM or casting with tooling, but in many cases also potentially faster than simulation. Grid Logic often finds that the quickest way to evaluate a design is simply to print it and have a part in hand within a day or two, as opposed to waiting for a computer. The speed promises rapid design iteration as well as a shorter route to near-net-shape metal parts.

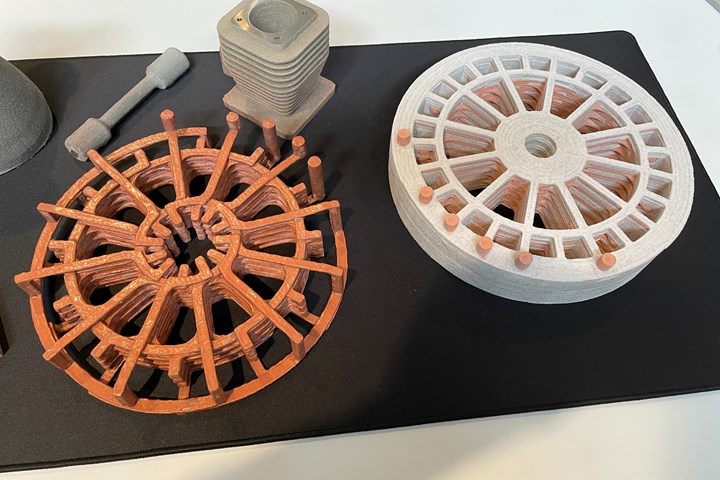

But Grid Logic’s process can also do things that are difficult or impossible with other manufacturing methods, even many forms of 3D printing. Each printer can accommodate multiple powder feeders in addition to the one used for sand, so it is possible to print with multiple materials as long as they are compatible in sintering. The multimaterial capabilities and lack of heat in the process also allow for easier processing of high-entropy and magnetic powders, where the high-value functional material could be placed just where needed inside of a larger structure.

Not only can Grid Logic print with copper, it can also combine this material with others. The completed three-phase stator coil on the right pairs a copper interior with alumina for insulation, printed together at the same time.

The next step for Grid Logic is scale. That could mean building more machines for production, but it could also mean building different types of machines, like larger scale printers with two or more nozzles running in parallel in different build zones.

“We may even build custom machines for sale at some point,” Holcomb says, “but for now, the emphasis is on parts no one else can make.”

Related Content

BMF Receives FDA Clearance for UltraThineer Dental Veneer Material

The zirconia materials are now qualified for use in the production of the world’s thinnest cosmetic veneers, which require significantly less tooth preparation or grinding, thereby preserving more of the patient’s natural enamel.

Read MoreFormlabs Expands SLA/SLS Ecosystem With New Materials, Postprocessing Tools

The new hardware, software and materials are designed to streamline postprocessing and unlock new workflows.

Read More3D Printed Reactor Core Makes Solar Fuel Production More Efficient

The solar reactor uses water and CO2 from the air and sunlight as the energy source to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

Read MoreMoldJet Technology Enables High-Throughput Metal, Ceramic Additive Manufacturing

Formnext 2023: Tritone Technologies’ additive manufacturing solutions enable industrial throughput of accurate parts with a range of metal and ceramic materials.

Read MoreRead Next

Finland Sees Swifter Castings Through Hybrid Manufacturing

Combining sand 3D printing with casting has enabled Hetitec Oy to meet the underserved small-batch Finnish casting market — in some cases, producing high-priority parts in under a week.

Read MoreVideo: Additive Manufacturing as an Alternative to Casting

Daan Kersten of Additive Industries discusses the promise of metal AM for production. Cost per piece can be lower than many expect.

Read MoreUnusual Forms of 3D Printing, and How to Categorize This Technology: AM Radio #21A

In this episode of AM Radio, Stephanie Hendrixson and Peter Zelinski quiz each other on six 3D printing processes — some common, some novel. Test your own knowledge and stick around for a discussion about how to categorize (or maybe re-categorize) AM technologies.

Read More

.jpg;width=70;height=70;mode=crop)