Velo3D’s Flow 5.0 Software Enhances Control Over 3D Printing Process

The software’s new features include user-selectable core parameters, preprint analysis to identify potential costly and time-consuming errors, and rapid resequencing for multipart prints.

Share

Read Next

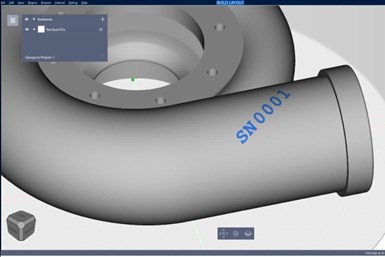

With the new labeling module in Flow 5.0, users can quickly add text to the print file, enabling serialization of parts or other identifying marks. Photo Credit: Velo3D

Velo3D, a metal additive manufacturing (AM) technology company for mission-critical parts, has updated its Flow print preparation software. Flow 5.0 was developed to unlock an array of new capabilities for engineers using Velo3D’s fully integrated solution, including user-selectable core parameter sets that provide enhanced control over builds with the ability to assign different parameters to any part on the build plate. This improvement, in addition to Flow’s ability to apply skin and contour overrides, gives customers enhanced control over the final material properties of printed parts.

“Through our software, we are able to continually expand our manufacturing capabilities based on customers’ needs and feedback,” says Alexander Varlahanov, vice president of engineering at Velo3D. “By enabling selectable core parameters for customers, engineers can modify the material properties of their parts to better suit the need of the application, including more isotropic parts. This even works on builds with multiple types of parts where each requires a different core parameter set.”

Flow 5.0 includes checks and messages that identify possible errors before a build even starts, reducing the likelihood of customers experiencing failures in their builds. In doing so, engineers can be confident that a part will print successfully before the process begins. Flow also includes labeling for objects. Customers can easily add alphanumeric characters, such as serial numbers or other unique identifying text, to their builds within the Flow print preparation software to clearly identify and label instances of their parts. Once the print file is produced, the characters can be updated through a Label Updater tool.

The release also enables a faster method to calculate build times for builds of different part quantity. After a part has been prepared for print, users can vary the quantity of that part and see updated build times to better understand the economics of scaled production. This enables contract manufacturers to speed up their quoting process and accelerate OEM planning and scheduling.

The Flow print preparation software is a key part of Velo3D’s fully integrated metal AM solution. The software takes traditional CAD files and turns them into print files without any specialization or design for additive manufacturing (DfAM). Other parts of the solution include the Sapphire family of printers, Assure quality assurance software, and the underlying Intelligent Fusion manufacturing process that ensures consistent, repeatable outcomes across different Sapphire printers from the same print file.

- Read about Visser Precision joining Velo3D’s Global Contract Manufacturing Network after purchasing and receiving two Velo3D Sapphire printers to expand its additive manufacturing capabilities for its aerospace customers.

- Learn about Zeda’s new additive manufacturing factory in Ohio which will provide medical, military and aerospace production. The site features laser powder bed fusion machines from Velo3D.

- Check out this post about 3D printed metal parts going hypersonic at zero mph. Purdue Researchers are using additively manufactured injector components from Velo3D to create Mach 6 conditions for a ground-testing facility.

Related Content

Spherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read More3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More