Metal

Volkmann Modular Powder Supply Stages Material in High Volumes

The Metal Powder Supply hopper holds material in process and, once collected, the recovered metal powders may be screened and reintroduced to the printing process or stored for future reuse.

Read MoreSolukon Names US Distribution Partners

Solukon’s distribution partners in the U.S. include DMARK Corp., Hartwig, MAHAR, Phillips Corp. and BahFed.

Read MoreVelo3D Qualifies Aluminum Alloy to Support Formula 1 Customers

Aluminum alloy supports Formula 1 customers by enabling the production of parts requiring high thermal conductivity and durability, and is available to print in both 50 and 100 micron layers.

Read MoreMaterialise Opens Medical 3D Printing Facility

At the new facility in Plymouth, Michigan, Materialise specializes in the 3D printing of personalized titanium cranio-maxillofacial (CMF) implants for more patient-specific care.

Read MoreDyndrite Joins NMIS to Advance 3D Metal Manufacturing Research

Dyndrite has joined NMIS to help develop build recipes and shareable knowledge in materials process development across all major laser powder bed fusion OEM file formats.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

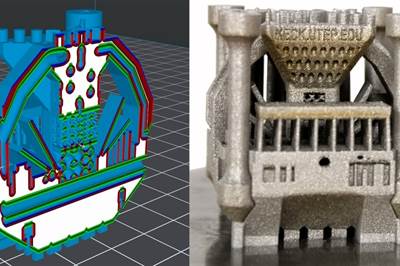

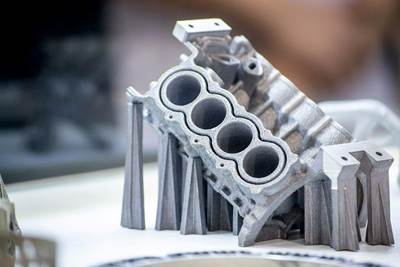

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAddUp Adds Constellium’s Aheadd CP1 Aluminum Alloy to Material Portfolio

The Aheadd CP1 aluminum alloy was developed by Constellium for the needs of additive manufacturing by laser powder bed fusion specifically for high-performance and lightweight applications.

Read MoreAmerica Makes Offers Additive Manufacturing Research Grants Worth Nearly $12 Million

This project call for additive manufacturing research projects offers the largest funding opportunity launched by America Makes since its inception in 2012.

Read MoreAmerica Awards Research Funding to Colorado School of Mines

The project team will investigate cross-platform consistency in laser powder bed fusion technologies.

Read More