Machining

Additive Manufacturing Is More Than 3D Printing: The Importance of Complementary Capabilities (Video)

Vertex Manufacturing founder Greg Morris on machining, inspection and other operations that complete AM.

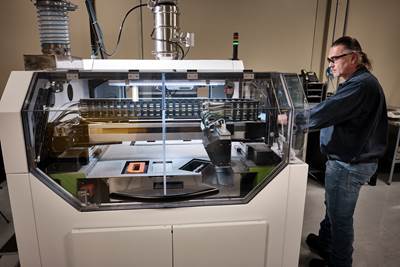

WatchAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreGE Additive Partners With Sydney University on Manufacturing-Focused Research Facility

The Sydney manufacturing hub is a new manufacturing-focused research facility that will work alongside industry to deliver cutting-edge R&D in additive manufacturing and materials processing.

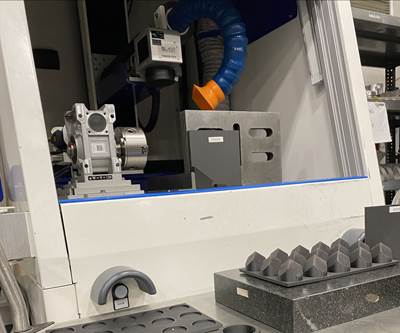

Read MoreFor Automated Machining Business, 3D Printing’s Value-Add Keeps Adding Up

Through robot grippers, assembly aids, custom kits and coolant hardware, additive manufacturing impacts every stage of production.

Read MoreDoes Manufacturing Need Additive?

If a subtractive manufacturing operation is going smoothly, AM need not replace it. So what is AM good for, and why do we need it in the first place?

Read MoreCutting Tool Maker Succeeding With 3D Printed Carbide for Oil/Gas and Other Applications

Powders, parts and products are different ways the company is advancing with AM. Carbide and tools are separate areas of success.

Read MorePrototyping Is More Than Printing: The Cool Parts Show Bonus

We hear from students who carried out other steps, beyond the 3D printing, that went into evaluating a complex metal AM component.

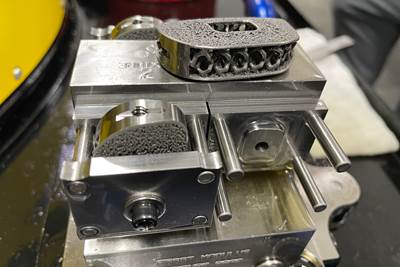

WatchMold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

Read MoreAirtech’s Dahltram Resins Qualified for Use on All CEAD AM Flexbot Platforms

The AM Flexbot is one of CEAD’s AM solutions, using Comau robots directly controlled by Siemens Sinumerik. It offers an option to combine 3D printing and milling into one automated process.

Read More3D Printed Tool for Machining Electric Vehicle Motors: The Cool Parts Show #39

Additive manufacturing achieves a large-diameter cutting tool light enough for fast, precise machining of the motor housing’s stator bore.

Watch